|

produk Nama |

Penyesuaian produk pengecoran mati paduan aluminium - pemasok pengecoran mati China berkualitas tinggi menyesuaikan produk pengecoran mati paduan aluminium, semua jenis produk pengecoran mati paduan aluminium diterima untuk disesuaikan |

|

Produksi TEKNOLOGI |

pemesinan CNC, teknologi pemotongan kawat, teknologi pelepasan listrik, teknologi pengecoran die, dll |

|

Bahan Mentah Bahan |

Paduan Aluminium |

|

Produksi Siklus |

45 hari untuk menyelesaikan produksi dan Pengiriman |

|

produk Harga |

Pabrik produksi sendiri, harga terendah |

|

produk kualitas |

Produk memiliki kualitas yang ketat tahap pemeriksaan, sesuai dengan kebutuhan pelanggan untuk menyediakan laporan PPAP |

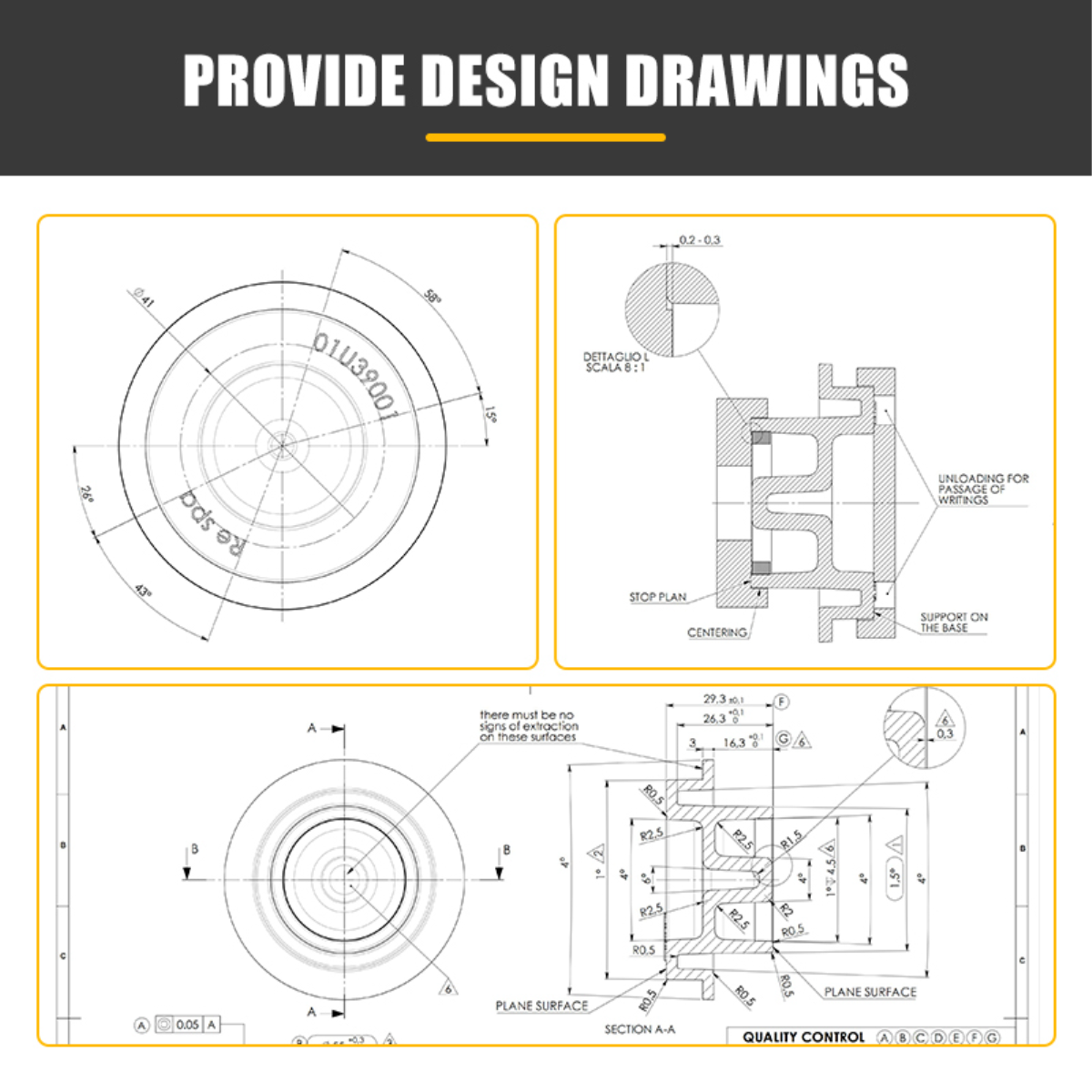

Pelanggan menyediakan gambar

Diproduksi sesuai dengan persyaratan pelanggan

Kontrol kualitas produk dan pengaturan pengiriman

| Bahan produk | ADC12,ADC14,A380,A354,A356,ALSi10Mg,ALSi10Mg(Fe),ALSi12Fe,ALSi8,ALSi9CU3,HA7-M |

| Perlakuan Permukaan | Peleburan AL, Pengecoran cetak, Penghapusan bur, Mesin CNC, Pembersihan, Pelapisan, PowderCoating, Perakitan & Uji kebocoran 100%; |

| Ukuran | 1, Menurut gambar pelanggan |

| Format Gambar | step, dwg, igs, pdf |

| Sertifikat | ISO 9001:2015 & IATF 16949; IEC 62321; ISO 45001; ISO 50001; ISO 14001; |

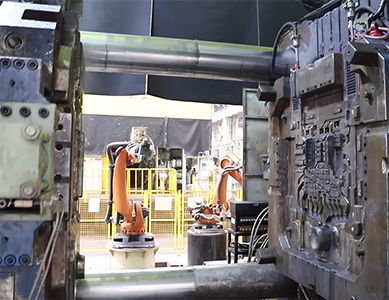

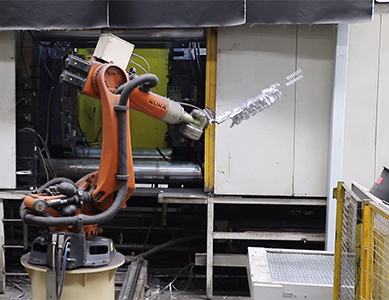

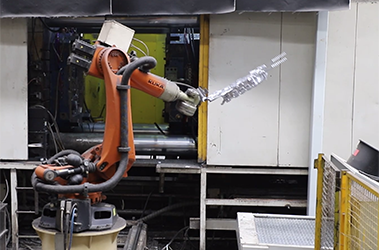

| Perangkat produksi pengecoran cetak | Lebih dari 60 mesin produksi pengecoran cetak. Semua mesin dilengkapi dengan sistem pengangguran otomatis, sistem penyemprotan otomatis, sistem konveyor ekstraktor otomatis dan tungku pemegang untuk mesin berkapasitas besar dilengkapi dengan lengan robot ABB dan robot penyemprot KUKA untuk meningkatkan efisiensi operasi dan kualitas yang stabil. 180T,280T,350T,420T,500T,560T,630T,800T,1250T,1600T,2000T,2500T,4000T |

| Tungku peleburan pusat LPG/Gas Alam | 8 unit tungku peleburan pusat LPG/ Gas Alam. Dilengkapi dengan unit kontrol suhu alat dan unit vakum untuk meningkatkan kualitas dan stabilitas produk. |

| Pusat Pemesinan CNC & Dukungan | 600 set pusat mesin CNC (terdiri dari US HAAS VF3, Jepang FanucT14i-Ee, Taiwan Wintec-MV45, US Akira Seiki) dan 5 set Korea KIA, LG MAZAK HMC. |

| E-Plating & Powder Painting | Kami memiliki pemasok pendukung yang khusus bergerak dalam pelapisan bubuk dan plating, termasuk Cu, Ag. Ni, Chromating, dll. Selain itu, kami memiliki berbagai peralatan inspeksi untuk pelapisan bubuk dan plating, seperti pengujian dampak, pengujian ketebalan film, pengujian perbedaan warna, pengujian kecerahan, pengujian semprotan garam. Alat-alat inspeksi ini dapat secara efektif mengontrol kualitas produk dan memperoleh kepercayaan pelanggan kami. |

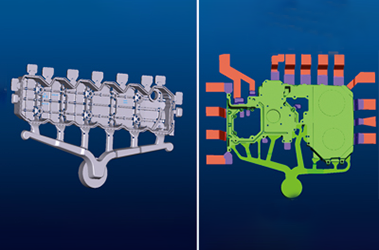

| perangkat lunak | ANYSAST,MAGMA,PRO-E,MASTER-CAM,AUTO-CAD,SOLIDWORKS |

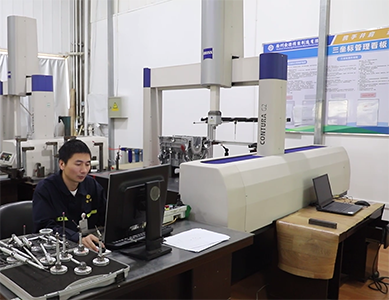

| Perangkat Inspeksi Utama | CMM, OBLE Spektrometer, Mesin Uji Universal, Mikroskop Metalografi, Mesin Analisis ROHS, Proyektor Optik, Mesin Pengujian NDT X-ray, Pengujian Keras Brinell |

| Kebijakan & Sistem Kualitas | APQP,SPC,MSA,FMEA,PPAP |

| bagian layanan: | 1, layanan online manual 24 jam; 2, satu tim layanan untuk melayani satu proyek; 3, mendukung komunikasi bahasa kecil; |

| Bagian teknologi | tujuh proses produksi, dukungan teknis, inspeksi kualitas, pembuatan cetakan, produksi pengecoran die, produksi mesin, proses pengolahan permukaan, fasilitas pendukung; |

| Bagian harga | Semua produk diproduksi di pabrik kami sendiri, harganya adalah yang terbaik di pasaran dan memiliki kinerja biaya terbaik; |

| Ukuran Pabrik | Kami memiliki 3 basis produksi kami sendiri, Weitang Auto Parts Casting Factory, Suzhou Jincheng Precision Casting Co., Ltd., Xuzhou Jincheng Precision Manufacturing Co., Ltd., skala total aset telah melebihi 1 miliar yuan, menempati lahan seluas hampir 300 mu, luas pabrik 180.000 meter persegi, dengan 60 jalur produksi pengecoran die-casting kamar dingin otomatis sepenuhnya dari 150~4.000 ton, lebih dari 600 set pusat mesin presisi canggih dan berbagai fasilitas pendukung serta alat ukur presisi besar dan peralatan puluhan unit. Fasilitas dan alat ukur presisi besar puluhan set, dengan kapasitas produksi tahunan 50.000 ton bagian dan komponen pengecoran die-casting aluminium untuk penelitian dan pengembangan, produksi, dan pemrosesan presisi; |

Profil Perusahaan

Perusahaan ini memfokuskan diri pada pengecoran die aluminium paduan dan mesin presisi untuk mobil tradisional, mobil energi baru, komunikasi, penyimpanan energi fotovoltaik, inverter, transportasi rel, penerbangan medis, dan komponen industri umum. Total aset perusahaan telah melebihi 1 miliar yuan, menutupi luas hampir 200.000 meter persegi, dengan luas area pabrik 180.000 meter persegi, dan merupakan perusahaan teknologi tinggi yang mengintegrasikan R&D dan produksi. Perusahaan memiliki 60 jalur produksi pengecoran die otomatis lengkap dengan ruang dingin berkapasitas 150 ~ 4000 ton, lebih dari 600 pusat mesin presisi canggih, serta berbagai fasilitas pendukung dan alat ukur presisi besar sebanyak puluhan unit. Kapasitas produksi tahunan mencapai 50.000 ton bagian dan komponen pengecoran die aluminium paduan dengan kemampuan riset, pengembangan, produksi, dan mesin presisi, sehingga mencapai efek produksi skala besar.

Pelanggan menyediakan gambar, dan kami memiliki insinyur pemodelan profesional untuk melakukan pemodelan 3D sesuai dengan gambar. Setelah pemodelan selesai, analisis aliran cetakan akan dilakukan untuk memeriksa apakah ada masalah dalam cetakan, dan produksi cetakan akan dilakukan setelah memastikan bahwa cetakan benar.

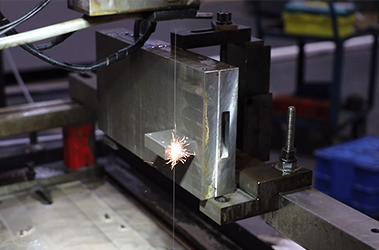

Memainkan peran penting dalam pembuatan cetakan, terutama dalam pengolahan bagian cetakan presisi tinggi dan bentuk kompleks. Perannya utama adalah pemrosesan presisi tinggi: mesin pemotongan kawat dapat memberikan akurasi pemrosesan yang sangat tinggi, cocok untuk membuat rongga kompleks, tepi potong, dan fitur halus dari cetakan presisi, seperti cetakan punch, lubang presisi, tepi tidak beraturan, dan sebagainya.

Peralatan presisi untuk pemrosesan bahan logam tanpa kontak menggunakan prinsip pelepasan listrik. Perannya yang utama adalah dalam proses pembuatan cetakan, untuk pemrosesan presisi baja cetakan atau bahan logam lain yang sulit diproses, terutama untuk bentuk kompleks, material dengan kekerasan tinggi, rongga, lubang, dan struktur mikro.

Digunakan terutama untuk penggerindaan presisi permukaan benda kerja untuk mencapai ketebalan, kehalusan, dan ketelitian dimensi yang diinginkan.

Menyediakan solusi efisien, presisi tinggi, dan stabil untuk pemrosesan cetakan, dan merupakan peralatan pengolahan kelas tinggi yang tidak tergantikan dalam industri pembuatan cetakan.

Setelah melalui proses produksi yang ketat, penyelesaian akhir pembuatan cetakan, dan pemeriksaan kualitas cetakan, kualitas cetakan yang diproduksi terjamin.

Pelelehan paduan aluminium dalam tungku.

Injeksi 4000T untuk pekerjaan

Persiapan cetakan pada mesin injeksi

Produk Ekstraksi Lengan Robotik

Pemoles produk oleh pekerja ahli

Mesin blast pasir untuk melaksanakan pekerjaan dan mengintegrasikan produk

Pengujian kualitas produk di laboratorium. pengujian bahan produk

Pemeriksaan koordinat dimensi produk

Peralatan imersi untuk menguji ketatnya produk terhadap udara

Uji ketat udara dengan air untuk mendeteksi ketatnya produk terhadap udara

Pengujian ketat udara mendeteksi ketatnya produk terhadap udara

Pembersihan ultrasonik pada permukaan produk untuk menjaga kebersihannya

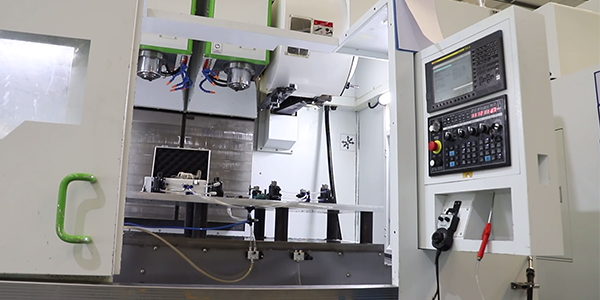

| nama mesin | Perangkat pusat mesin CNC vertikal (spindle ganda) |

| Keunggulan Kinerja Mekanis |

1. Meningkatkan efisiensi pemrosesan 2. Mengurangi jumlah pengikatan 3. Pemrosesan bagian kompleks 4. Mengurangi jejak lahan 5. Mengurangi biaya operasional 6. Meningkatkan presisi dan kualitas 7.Penggantian alat cepat dan fleksibilitas |

| nama mesin | Peralatan pusat mesin CNC (horizontal) |

| Keunggulan Kinerja Mekanis |

1.Meningkatkan kestabilan dan presisi pemrosesan 2.Meningkatkan efisiensi pemrosesan 3.Cocok untuk pengolahan benda kerja besar dan kompleks 4.Tingkat otomasi dan integrasi yang tinggi 5.Fleksibilitas dan serbaguna 6.Pengoptimalan penghilangan chips dan pendinginan 7.Cocok untuk cetakan presisi dan kompleks |

Wire EDM adalah alat pendukung yang kuat dalam pembuatan cetakan. Ini memainkan peran yang tidak dapat digantikan dalam meningkatkan keakuratan, kompleksitas, kecepatan pengembangan, dan efisiensi biaya cetakan, serta merupakan alat teknis yang tidak terpisahkan dalam industri manufaktur cetakan.

WEDM adalah pemrosesan tanpa kontak, tidak menghasilkan stres mekanis pada benda kerja, yang membantu mempertahankan sifat asli material cetakan, mengurangi deformasi, dan memperpanjang umur cetakan.

Dalam proses pembuatan cetakan, baja cetakan atau material logam lainnya yang sulit diproses mengalami pemrosesan bentuk halus, terutama untuk rongga, lubang, dan mikrostruktur dengan bentuk kompleks dan material berkeras tinggi.

Mesin penyemprot pasir menggunakan pasir kaca untuk mengolah produk, tidak hanya untuk meningkatkan penampilan dan tekstur produk, tetapi juga untuk meningkatkan fungsinya dan ketahanannya, merupakan salah satu cara efektif untuk meningkatkan nilai tambah produk.

1. Penyumbatan mikroporus: meningkatkan kedap udara dari logam cor.

2. Meningkatkan kekuatan dan ketahanan

3. Mengurangi tingkat limbah untuk mengurangi biaya produksi dan meningkatkan tingkat produk jadi

Melalui mekanisme pembersihan fisik yang unik, ini memberikan solusi pembersihan yang efisien, ramah lingkungan, teliti, dan melindungi produk yang telah diproses, yang sangat penting dalam industri dengan manufaktur presisi dan pengendalian kualitas yang ketat.

Paduan aluminium dilelehkan pada suhu lebih dari 700 derajat Celsius dan material cair tersebut kemudian dituangkan ke dalam cetakan injeksi.

Kami memiliki mesin casting injeksi 180T~4000T, semua produk mesin casting paduan aluminium dapat diproduksi, cukup berikan gambar;

Perusahaan memiliki lebih dari 60 lini produksi otomatis, yang dapat memproduksi produk yang dibutuhkan pelanggan tanpa henti, dan produk-produk tersebut memiliki pengendalian kualitas yang ketat.

| 1. Keunggulan teknis |

1. Ahli industri die casting lebih dari 20 orang, insinyur profesional mold lebih dari 80 orang; 2. Desain 3D, analisis aliran mold, pembuatan mold, analisis proses die casting (layanan khusus); |

| 2. Keunggulan pemantauan kualitas |

1. Lebih dari 10 insinyur kualitas, tim pengendalian kualitas khusus; 2. Jumlah peralatan uji 10; 3. Sertifikasi: sistem kualitas internasional ISO9001:2008; sertifikasi sistem ISO14001:2004; sertifikasi sistem kualitas industri otomotif ISO/TS16949:2002; |

| 3. Keunggulan pembuatan mold |

1. Insinyur desain cetakan, dapat menggunakan perangkat lunak PRO-E, VG, dan lainnya; 2. Peralatan canggih, pusat mesin HAAS, CNC gantry, dll., lebih dari 49 peralatan, produksi tahunan 300 set mold die casting; 3. Kami dapat mendesain mold untuk pelanggan (menyediakan layanan khusus) |

| 4. Keunggulan manufaktur die casting |

1. 57 set lini produksi, dengan kapasitas tahunan 50.000 ton bagian die-casting aluminium; 2. Tingkat produksi cerdas: mesin sup otomatis, mesin semprot otomatis, mesin pengambil otomatis, konveyor otomatis, mesin pendinginan titik tekanan tinggi, peralatan pemotongan dan penyetelan; 3. Desain produk yang fleksibel, untuk memberikan solusi produksi, untuk memberikan kondisi bagi produksi dalam jumlah kecil |

| 5. Keunggulan mesin ditambah manufaktur |

1. Lebih dari 600 set mesin penggilingan CNC dan lebih dari 60 set pusat penggilingan horizontal; 2. Insinyur pemrograman CNC total 30 orang, 30 insinyur proyek dan personel teknis; |

| 6. Keunggulan teknologi pengolahan permukaan |

1. Perusahaan pendukung pengecatan mandiri; 2. Bengkel penyemprotan bebas debu seratus ribu, tiga jalur penyemprotan, dua belas pistol penyemprotan elektrostatik impor, empat jalur produksi galvanis otomatis, dua jalur produksi pra-pengolahan; 3. Peralatan pengujian pengecatan dan elektroda yang lengkap; |

| 7. Fasilitas pendukung |

1. Bengkel bersih: bengkel GP12 bersih seluas 1000 meter persegi; 2. Stasiun pemantauan produk; 3. Peralatan uji ketat gas; 4. Peralatan infiltras; 5. Mesin pembersih produk otomatis; |