| 1, kelebihan teknikal |

1, pakar industri pemutus mati lebih daripada 20 orang, jurutera profesional acuan lebih daripada 80 orang; 2, reka bentuk 3D, analisis aliran acuan, pembuatan acuan, analisis proses tuangan (perkhidmatan tersuai) |

| 2, kelebihan pemantauan kualiti | 1, lebih daripada 10 jurutera kualiti, pasukan kawalan kualiti khas; 2, bilangan peralatan ujian 10; 3, pensijilan: ISO9001: 2008 sistem pensijilan kualiti antarabangsa; pensijilan sistem ISO14001: 2004; ISO/TS16949: 2002 Pensijilan sistem kualiti industri automotif; |

| 3, Kelebihan pembuatan acuan | 1, jurutera reka bentuk acuan, boleh PRO-E, VG dan perisian lain; 2, peralatan canggih, pusat pemesinan HAAS, gantri CNC, dll., lebih daripada 49 peralatan, keluaran tahunan sebanyak 300 set acuan pemutus die; 3, boleh mereka bentuk acuan untuk pelanggan (menyediakan perkhidmatan tersuai) |

| 4, kelebihan pembuatan die casting |

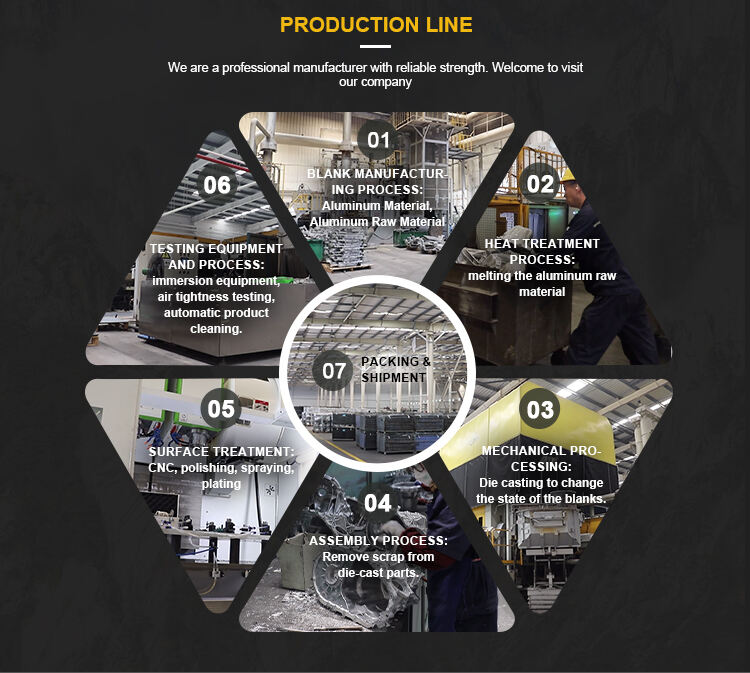

1, 57 set barisan pengeluaran, dengan kapasiti tahunan 50000 tan bahagian die-casting aloi aluminium; 2, tahap pengeluaran pintar: mesin sup automatik, mesin semburan automatik, mesin pick-up automatik, tali pinggang penghantaran automatik, mesin penyejukan titik tekanan tinggi, peralatan memotong dan membentuk; |

| 5, Mesin ditambah kelebihan pembuatan | 1, lebih daripada 600 set mesin pemesinan CNC dan lebih daripada 60 set pusat pemesinan mendatar; 2, jurutera pengaturcaraan pemesinan CNC seramai 30 orang, 30 kejuruteraan projek dan kakitangan teknikal; |

| 6, kelebihan teknologi rawatan permukaan |

1, syarikat sokongan penyaduran semburan bebas; 3, peralatan ujian penyemburan dan penyaduran lengkap; |

| 7, Kemudahan sokongan |

1, bengkel bersih: 1000 meter persegi bengkel bersih GP12; 2, stesen pemantauan produk; 3, peralatan ujian sesak udara; 4, peralatan penyusupan; 5, produk mesin pembersihan automatik; |

Jincheng

Introducing the Custom High Precision Die Casting Aluminum Housing designed specifically for New Energy Vehicles. The product is manufactured by a well-known brand in the automotive industry.

Designed to meet up the demanding needs of modern-day electric vehicles. The aluminum housing is made to be highly durable and resist extreme temperatures making it ideal for harsh operating conditions.

Created to ensure that the motor other critical components operate at a temperature is optimal. It is prepared with a high-precision process is die-casting enhances the overall quality making sure the housing is suitable for use in high-performance applications.

Created to be economical supplying a dependable and solution is efficient automobile manufacturers looking to reduce production costs while keeping top-quality standards.

The product is easy to install which makes it perfect for both new and cars existing.

Designed to become very stylish having a design is minimalistic blends seamlessly with the vehicle's general design. The aluminum housing provides heat is very good which guarantees the longevity and dependability of vehicle elements.

Perfect to be used in numerous applications automotive. It can be utilized for electric power steering battery management systems and other vehicle is critical.

Environmentally friendly because it is produced from recycled aluminum. This makes it an option is great vehicle manufacturers looking to reduce their carbon impact and meet industry standards on sustainability.

The Custom High Precision Die Casting Aluminum Housing for Integrated Motor Controller New Energy Vehicles Heatsink Box is an excellent addition to any electric vehicle. It offers a reliable efficient solution for maintaining the optimal temperature for critical vehicle components all while being cost-effective and environmentally friendly. with Jincheng's reputation for high-quality this product is sure to exceed any customer's expectations.