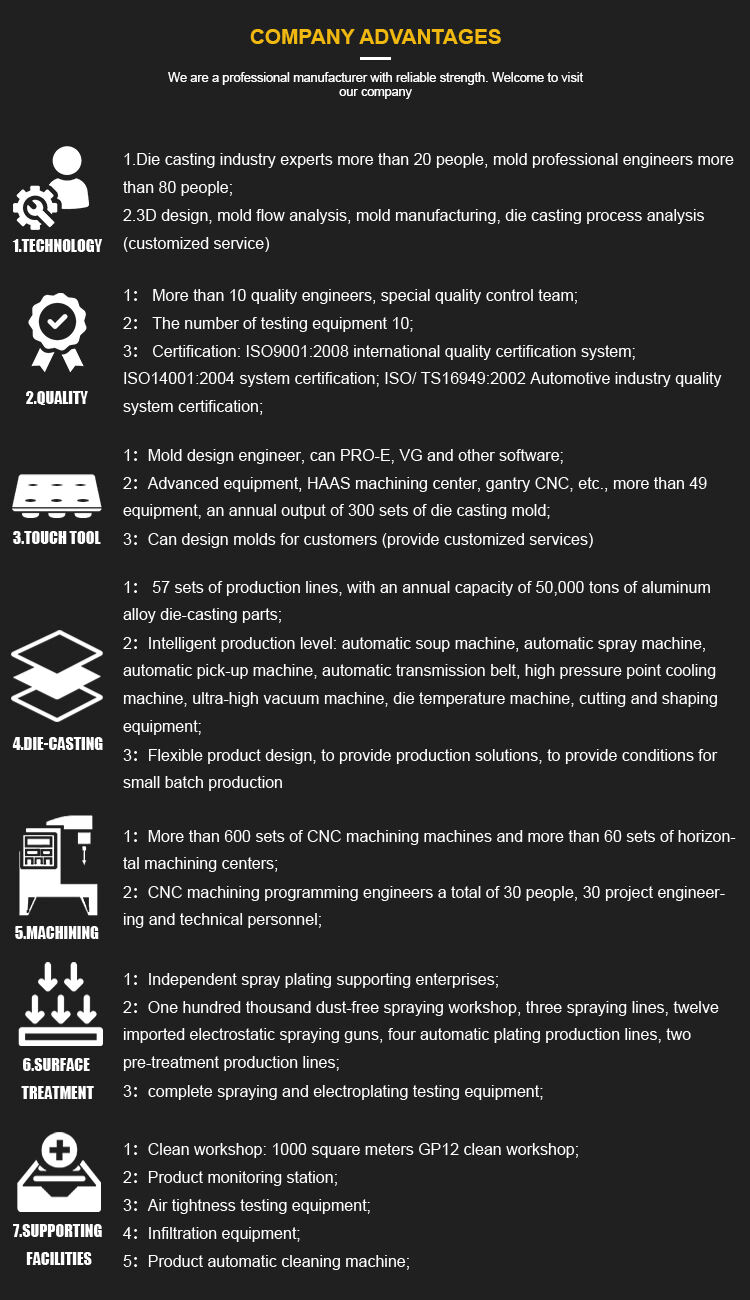

| 1, Teknisk fordel |

1, dø-avstøpning industrieksperter mer enn 20 personer, mold profesjonelle ingeniører mer enn 80 personer; 2, 3D-design, støpestrømsanalyse, støpeformproduksjon, støpeprosessanalyse (tilpasset service) |

| 2, Kvalitetsovervåking fordel | 1, mer enn 10 kvalitetsingeniører, spesielle kvalitetskontrollteam; 2, antall testutstyr 10; 3, sertifisering: ISO9001: 2008 internasjonal kvalitet sertifiseringssystem; ISO14001: 2004-systemsertifisering; ISO/TS16949: 2002 Sertifisering av bilindustriens kvalitetssystem; |

| 3, Fordeler med muggproduksjon | 1, mold design ingeniør, kan PRO-E, VG og annen programvare; 2, avansert utstyr, HAAS maskineringssenter, portal CNC, etc., mer enn 49 utstyr, en årlig produksjon på 300 sett med støpestøpeform; 3, kan designe former for kunder (gi tilpassede tjenester) |

| 4, Die casting produksjon fordeler |

1, 57 sett med produksjonslinjer, med en årlig kapasitet på 50000 XNUMX tonn aluminiumslegering støping deler; 2, intelligent produksjonsnivå: automatisk suppemaskin, automatisk sprøytemaskin, automatisk hentemaskin, automatisk girreim, høytrykkskjølemaskin, skjære- og formingsutstyr; |

| 5, Maskin pluss produksjonsfordel | 1, mer enn 600 sett med CNC-maskiner og mer enn 60 sett med horisontale bearbeidingssentre; 2, CNC Maskinering programmering ingeniører totalt 30 personer, 30 prosjekt ingeniører og teknisk personell; |

| 6, Overflatebehandling teknologi fordeler |

1, uavhengig spray Plating støtte bedrifter; 3, komplett sprøyting og galvanisering testing utstyr; |

| 7, Støtteanlegg |

1, rent verksted: 1000 kvadratmeter GP12 rent verksted; 2, produkt overvåking stasjon; 3, lufttetthet testing utstyr; 4, infiltrasjon utstyr; 5, produkt automatisk rengjøring maskin; |

Jincheng

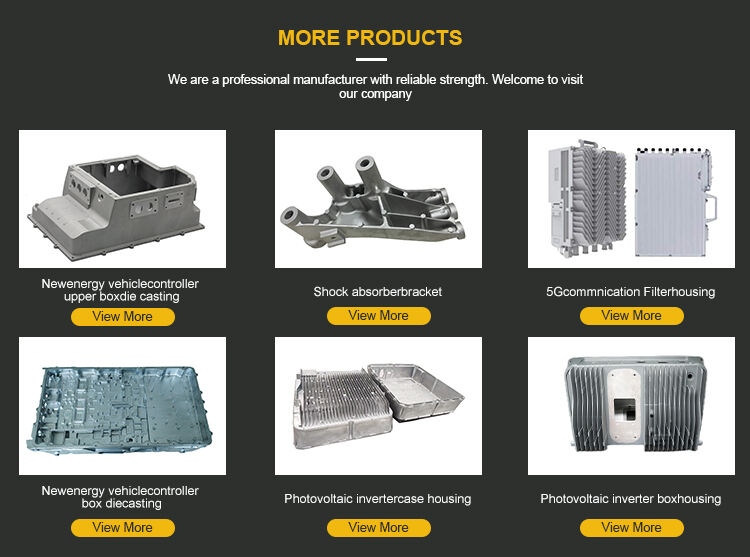

Die Casting Die Manufacturer presents superior quality New Energy Aluminum Alloy Parts quintessential. The New Energy Aluminum Alloy Parts are engineered to cater to diverse industrial needs and are an ideal solution for various applications.

The Worm Gearbox Crankcase Cover, also known as the new energy gearbox housing, is made of high-quality materials and cutting-edge technology. New energy aluminum alloy components ensure enhanced product durability, high strength and excellent corrosion resistance.

Jincheng is a professional die casting mold manufacturer, aiming to provide high efficiency and high performance products. The Worm Gearbox is composed of aluminum alloy which makes it corrosion-resistant and light-weight which improves durability and reduces maintenance costs. The Crankcase Cover Cylinder block(New energy gearbox housing) is a part is essential of vehicle engine and provides an airtight seal throughout the crankcase preventing any contamination in the engine. Crankcase covers are ideal for building high-end engines, especially for electric cars.

The Worm Gearbox Crankcase Cover is eco-friendly, energy-efficient and durable, suitable for a variety of energy saving and safety environmental protection requirements. The item offers high accuracy is dimensional various components facilitating seamless integration into the system.

Has many years of experience in providing items top-quality customers throughout the world. The organization follows a stringent quality control procedure to ensure that the items are regarding the standard is highest and provide the most performance to the clients. The company believes in providing customer is excellent and technical support to its customers after-sales.

Jincheng Die Casting Die Manufacturer has brought a quality product to the efficient market durable and sustainable. The Worm Gearbox Crankcase Cover Cylinder Block(New energy gearbox housing) and other New Energy Aluminum Alloy Parts are engineered to perfection delivering a flawless and smooth performance.