| Emri i produktit |

Kabina e personalizuar e motorit tre-një për automjet me energji të re |

| Tecnologji e prodhimit |

Makinim CNC, teknologji larg me kabel, teknologji lejet elektrike, teknologji diecasting, etj |

| Materiale të Thjeshta | Llaguri alumini |

| Cikli i prodhimit | 45 ditë për të përfunduar prodhimin dhe dorimin |

| Çmimi i produkteve | Prodhimi në fabrikë e vet, çmimi më i ulët |

| Kualiteti i Produktit | Produkti ka një lidhje e rëndësishme kontrolli kualiteti, sipas nevojave të klientit për të parashtruar raportin PPAP |

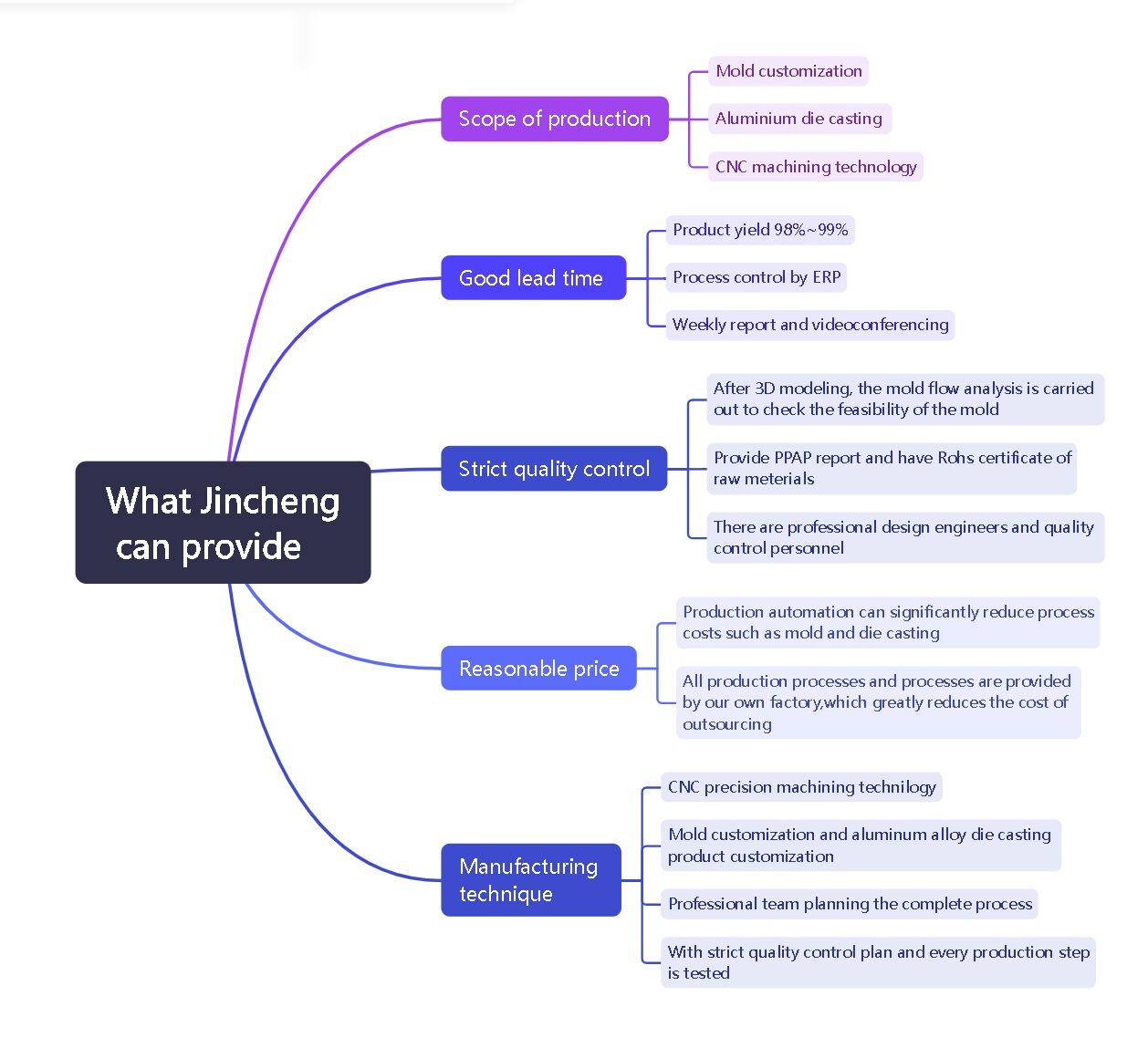

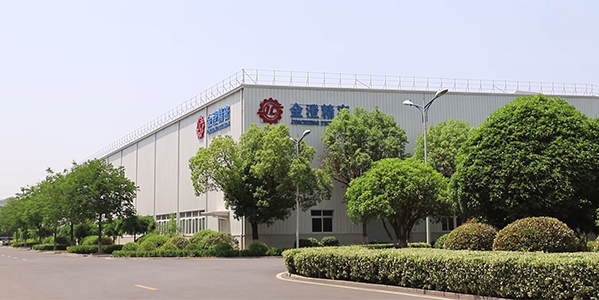

Larg Shtetit Suzhou Jincheng Precision Casting Co., Ltd. u fondua në vitin 2006, specializuar në gjetitje të kurbërave të hapur dhe ftofit të përpjekur për automjet tradicionale, automjet me energji e re, komunikim, energji fotovoltike, invertere, transport rrotullor, mjeksi dhe aviacion, dhe pjesë industriale të përgjithshme. Në vitin 2022, Xuzhou Jincheng Precision Manufacturing Co., Ltd. u bë të plotësisht e poseduar nga Xuzhou Jincheng, dhe shkalla e plotë e varfave ka kaluar 1 miliard yuan, me një sipërfaqe të 28 hektarëve dhe një zonë fabrike të 180.000 metra katror. Kompania është një ndërmarrje larg tehnologjik që integron R&D dhe prodhim. Kompania ka 60 linja produksionesh të plotësisht automatike të gjetitjeve të kurbërave të hapur me madhësi 150 ~ 4000 kg, makinash të avancuara të ftofit të përpjekur mbi 600, dhe të gjitha llojet e pajisjeve sërbore dhe makinash të matjes së precize të madhe dhe pajisje të drejtat, me kapacitet të prodhimit vjetor të 50.000 tone të pjesëve dhe komponenteve të gjetitjeve të kurbërave të hapur të hapur dhe të ftofit të përpjekur, duke arritur efektin e prodhimit në vellimi.

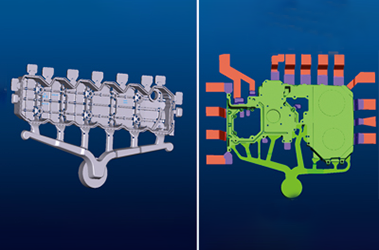

Klienti përgatiton shkallat, dhe ne kemi inxhinierë modeluese profesioniste që zgjerojnë modelim 3D sipas tyre. Pas përfundimit të modelimit, do të bëhet analiza e rritjes së formës për të kontrolluar nëse ka probleme në formën, dhe prodhimi i formave do të vazhdojë pas sigurisë se forma është e sakta.

Ajo luaj rëndësi të rëndë në lëshimin e formave, veçanërisht në procesin e pjesave të formave me precizion larg dhe formë komplekse. Rolu i saj kryesor është fletillimi me precizion: mashinat e largtijes së dradhit mund t'i ofrojnë akuracitet procesor të larg të thellë, e përshtatshme për prodhimin e holleve të kompleksa, krahër dhe karakteristikave të detajuara të formave të precize, si p.sh. format larg, lojër precize, brina jo rregullare dhe të tilla tjera.

Ekipamente me precizion për procesimin pa kontakt të materialeve metalike duke përdorur principin e largimit elektrik. Rolu i saj kryesor është në procesin e prodhimit të formave, për procesimin detajuara të acjarit të formave ose të tjera materiale metalike që janë të vështira për procesim, veçanërisht për formimet e formave komplekse, holle dhe strukturat mikro të materialave me larg dhe të erdhe.

Përdoret kryesisht për gresjen e precize të sipërfaqes së pjesës të punës për të arritur nivelin e nevojshëm të rrafshmit, finish dhe akuratësisë dimensionale.

Ofron zgjidhje eficiente, me precizion larg dhe stabilitet larg për procesimin e formave dhe është një pajisje procesimi larg e ndonjësishme në industrijën e prodhimit të formave.

Pas procesit të shumtëfushëm të prodhimit, plotësohet prodhimi i formave, dhe pastaj bëhet inspeksioni i cilësisë së tyre për të siguruar cilësinë e tyre.

Specializohet në automjete tradicionale, vehicle me energji të re, komunikime, energji fotovoltaike, depozitimi, invertere, transport rrotullor, aviacion mjeke dhe pjesë industriale të përgjithshme nga lekaje die casting, larg dhe procesim preciz.

Madhësia e plotë e varurive të ndërfaqes ka kaluar 1 miliard yuan, ka një sipërfaqe prej gjerave 200.000 metra katror, sipërfaqja e fabrikeve është 180.000 metra katror, është një ndërmarrje larg dhe produksion të teknologjisë larg.

Zbatimi i ligjove të aluminjit në një kamin.

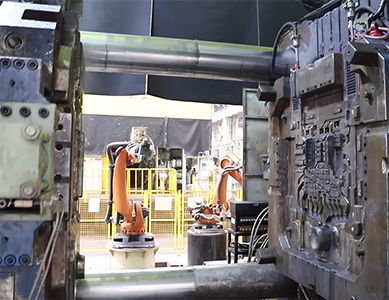

gjetitje 4000T në punë

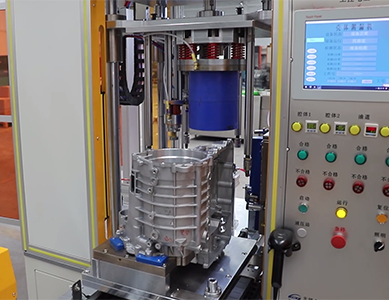

Përgatitja e formave në mashinari për gjetim me dhi

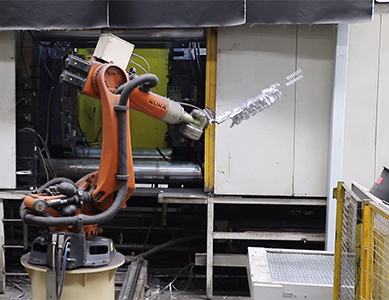

Produkte të ekstraktuara me kornizë robotike

Punonjesh që politojnë produkte

Makinë për shpargje abrasive për të kryer punën dhe të integrohet produkti

Testimi i kalitet të produkteve në laborator. Testimi i përbërësish të produkteve

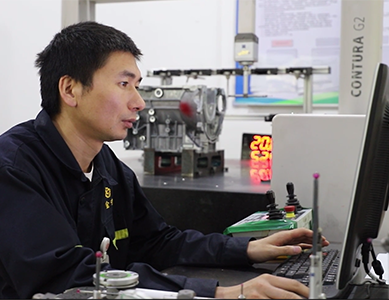

Koordinim i inspeksionit të dimenzioneve të produktit

Ekip i imersjes për të provuar sigurinën e prodhimeve

Provimi i sigurisë me ujë për të zbuluar sigurinën e prodhimeve

Testimi i sigurisë zbulon sigurinën e prodhimeve

Pastrojmë me ultrazot sipërfaqet e prodhimeve për të mbajtur ato të qeta

| 1. Larg dhe avantazhe teknike | 1. Ekspertë në industrinë e formave të gjasave mbi 20 njerëz, inxhinierë profesionistë të formave mbi 80 njerëz; 2. Dizajn 3D, analizë rrjedhore e formave, prodhim i formave, analizë e procesit të gjasave të formave (shërbim personalizuar) |

| 2. Avantazh monitorimi kualiteti | 1. Mbi 10 inxhinierë të kualitetit, ekip kontrolli kualiteti specializuar; 2. Numri i pajisjeve të provimit 10; 3. Larg: ISO9001:2008 sistem certifikimi kualiteti ndërkombëtar; Sistem certifikimi ISO14001:2004; Certifikim sistemi kualiteti industris automobilistike ISO/TS16949:2002; |

| 3. Larg nga avantazhet e prodhimit të formave | 1. Inxhinier dizajni formave, mund të përdor software PRO-E, VG dhe të tjerë; 2. Pajisje avancuara, qendra mashinxhere HAAS, CNC me hapsirë, etj., mbi 49 pajisje, prodhim vjetor 300 sete formash të gjasje; 3. Ne mund të projektojmë formash për konsumatorë (ofrojmë shërbime personalizuara) |

| 4. Avantazhet e prodhimit të gjasjes | 1. 57 rreshta produksionesh, me kapacitet vjetor 50000 tonë pjesë të gjasjes në allumin 2. Nivel inteligjent produksioni: makina tom kaq, makina e automatizuar për spritzim, makina e automatizuar për mbërthim, trasmision automatik, makina larg kalori në pikë të larg, pajisje për zgjerim dhe formim; 3. Dizajn produkti fleksibil, për të furnizuar zgjidhje për prodhim, për të parashtruar kushte për prodhim në grupe të vegjël |

| 5. Makinari plus lloji i larg |

1. Mbi 600 bashkëngjitje CNC dhe mbi 60 bashkëngjitje centra horizontale të punësimit; 2. Inxhinierë programues CNC gjithsej 30 njerëz, 30 inxhinierë dhe staf teknik për projekta; |

| 6. Tratime sipërfaqe avantazhe teknologjike |

1. Larg dhe shpejtësi ndërkombëtare që mbulon bizneset; 2. Atelier spritje pa dyqan në nivel njëqind mijë, tre linja për spritim, dymbdjhet pistole elektrostatike të importuara për spritim, katër linja automatike për kapsonj dhe dy linja për trajtim para kapsonjit; 3. Ekipi i plotë për larg dhe shpejtësi dhe trajtim; |

| 7. Larg dhe mbështetje | 1. Larg dhe montazh: 1000 metra katror GP12 larg dhe montazh; 2. Stacion monitorimi produkti; 3. Ekipi për provimin e sigurisë aerore; 4. Ekipi për infiltimit; 5. Mjekër automatik përshtatje produkti; |