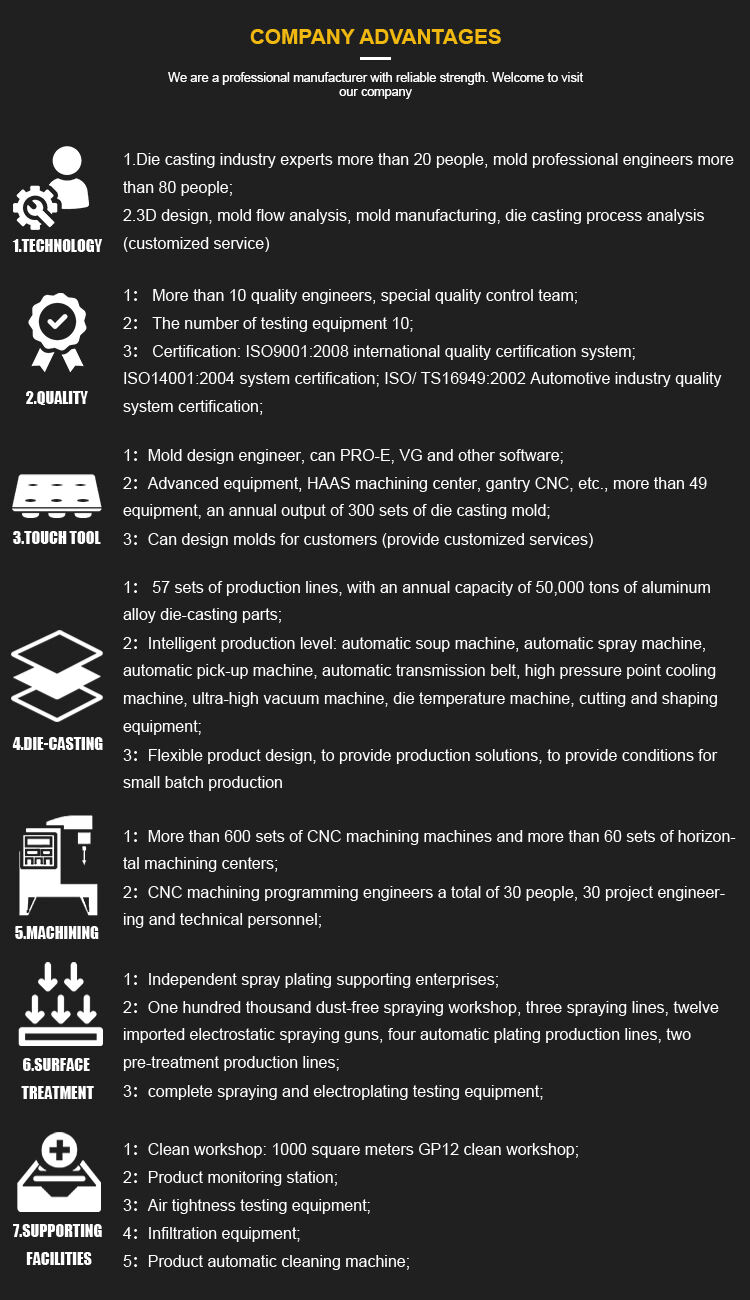

| 1, Teknikal na kalamangan |

1, mamatay casting industriya eksperto higit sa 20 mga tao, magkaroon ng amag propesyonal na mga inhinyero higit sa 80 mga tao; 2, 3D na disenyo, pagsusuri sa daloy ng amag, pagmamanupaktura ng amag, pagsusuri sa proseso ng die casting (pasadyang serbisyo) |

| 2, Kalamangan sa pagsubaybay sa kalidad | 1, higit sa 10 kalidad ng mga inhinyero, espesyal na kalidad ng control team; 2, ang bilang ng mga kagamitan sa pagsubok 10; 3, certification: ISO9001: 2008 internasyonal na kalidad certification systen; ISO14001: 2004 system certification; ISO/TS16949: 2002 Sertipikasyon ng sistema ng kalidad ng industriya ng sasakyan; |

| 3, Mga kalamangan ng paggawa ng amag | 1, amag disenyo engineer, maaari PRO-E, VG at iba pang software; 2, advanced na kagamitan, HAAS machining center, gantri CNC, atbp., higit sa 49 equipments, taunang output ng 300 set ng die casting mold; 3, maaaring magdisenyo ng mga hulma para sa mga customer (magbigay ng mga pasadyang serbisyo) |

| 4, Mamatay paghahagis pagmamanupaktura pakinabang |

1, 57 hanay ng mga linya ng produksyon, na may taunang kapasidad na 50000 tonelada ng mga bahagi ng aluminum alloy na die-casting; 2, intelligent na antas ng produksyon: awtomatikong sopas machine, awtomatikong spray machine, awtomatikong pick-up machine, awtomatikong transmission belt, mataas na presyon ng point cooling machine, pagputol at paghubog ng kagamitan; |

| 5, Machine plus pagmamanupaktura kalamangan | 1, higit sa 600 set ng CNC machining machine at higit sa 60 set ng horizontal machining centers; 2, CNC machining programming inhinyero ng isang kabuuang 30 mga tao, 30 proyekto engineering at teknikal na mga tauhan; |

| 6, Surface treatment teknolohiya bentahe |

1, independiyenteng spray kalupkop na sumusuporta sa mga negosyo; 3, kumpletong pag-spray at electroplating testing equipment; |

| 7, Pagsuporta sa pasilidad |

1, malinis na pagawaan: 1000 metro kuwadrado GP12 malinis na pagawaan; 2, istasyon ng pagmamanman ng produkto; 3, air tightness testing equipment; 4, kagamitan sa paglusot; 5, produkto awtomatikong paglilinis machine; |

jincheng

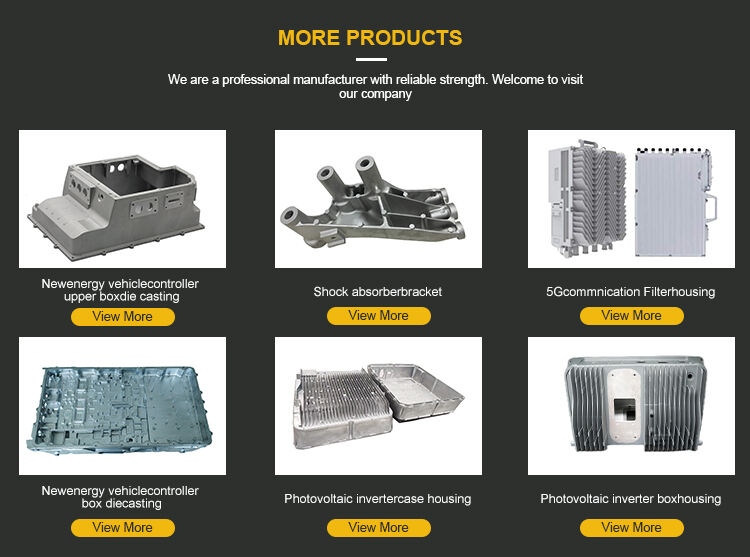

Die Casting Die Manufacturer presents superior quality New Energy Aluminum Alloy Parts quintessential. The New Energy Aluminum Alloy Parts are engineered to cater to diverse industrial needs and are an ideal solution for various applications.

The Worm Gearbox Crankcase Cover, also known as the new energy gearbox housing, is made of high-quality materials and cutting-edge technology. New energy aluminum alloy components ensure enhanced product durability, high strength and excellent corrosion resistance.

Jincheng is a professional die casting mold manufacturer, aiming to provide high efficiency and high performance products. The Worm Gearbox is composed of aluminum alloy which makes it corrosion-resistant and light-weight which improves durability and reduces maintenance costs. The Crankcase Cover Cylinder block(New energy gearbox housing) is a part is essential of vehicle engine and provides an airtight seal throughout the crankcase preventing any contamination in the engine. Crankcase covers are ideal for building high-end engines, especially for electric cars.

The Worm Gearbox Crankcase Cover is eco-friendly, energy-efficient and durable, suitable for a variety of energy saving and safety environmental protection requirements. The item offers high accuracy is dimensional various components facilitating seamless integration into the system.

Has many years of experience in providing items top-quality customers throughout the world. The organization follows a stringent quality control procedure to ensure that the items are regarding the standard is highest and provide the most performance to the clients. The company believes in providing customer is excellent and technical support to its customers after-sales.

Jincheng Die Casting Die Manufacturer has brought a quality product to the efficient market durable and sustainable. The Worm Gearbox Crankcase Cover Cylinder Block(New energy gearbox housing) and other New Energy Aluminum Alloy Parts are engineered to perfection delivering a flawless and smooth performance.