| 1, Technical advantage |

1, die casting industry experts more than 20 people, mold professional engineers more than 80 people; 2, 3D design, mold flow analysis, mold manufacturing, die casting process analysis(customized service) |

| 2, Quality monitoring advantage | 1, more than 10 quality engineers, special quality control team; 2, the number of testing equipment 10; 3, certification: ISO9001: 2008 international quality certification systen; ISO14001: 2004 system certification; ISO/TS16949: 2002 Automotive industry quality system certification; |

| 3, Advantages of mold manufacturing | 1, mold design engineer, can PRO-E, VG and other software; 2, advanced equipment, HAAS machining center, gantry CNC, etc., more than 49 equipments, an annual output of 300 sets of die casting mold; 3, can design molds for customers(provide customized services) |

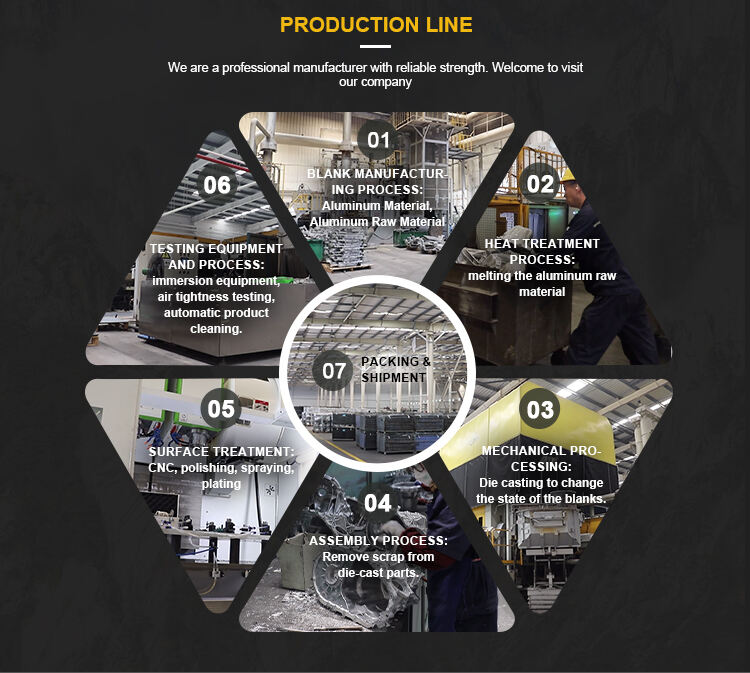

| 4, Die casting manufacturing advantages |

1, 57 sets of production lines, with an annual capacity of 50000 tons of aluminum alloy die-casting parts; 2, intelligent production level: automatic soup machine, automatic spray machine, automatic pick-up machine, automatic transmission belt, high pressure point cooling machine, cutting and shaping equipment; |

| 5, Machine plus manufacturing advantage | 1, more than 600 sets of CNC machining machines and more than 60 sets of horizontal machining centers; 2, CNC machining programming engineers a total of 30 people, 30 project engineering and technical personnel; |

| 6, Surface treatment technology advantages |

1, independent spray plating supporting enterprises; 3, complete spraying and electroplating testing equipment; |

| 7, Supporting facility |

1, clean workshop: 1000 square meters GP12 clean workshop; 2, product monitoring station; 3, air tightness testing equipment; 4, infiltration equipment; 5, product automatic cleaning machine; |

Jincheng

The 96626770 8440230 Right Side Engine Mounting Bracket may be the perfect solution Chevrolet Captiva 3.2L Engine Systems Support Foot Parts Suspension Parts.

Designed to provide superior support and security for the motor system.

Developed to withstand the temperatures that could be extreme pressures. Its construction ensures it could possibly provide the weight for the engine system without having any threat of failure or damage.

The installation is simple and, thanks to its precise design, it fits perfectly into the vehicle.

The Engine Systems Support Foot Parts Suspension Parts are designed, manufactured and tested to strict standards and are supported by General Motors.

Jincheng regularly updates production and service part designs to integrate new materials and technologies.

An excellent option for anyone trying to find a dependable engine systems suspension parts. Order yours and feel the distinction on your own today.