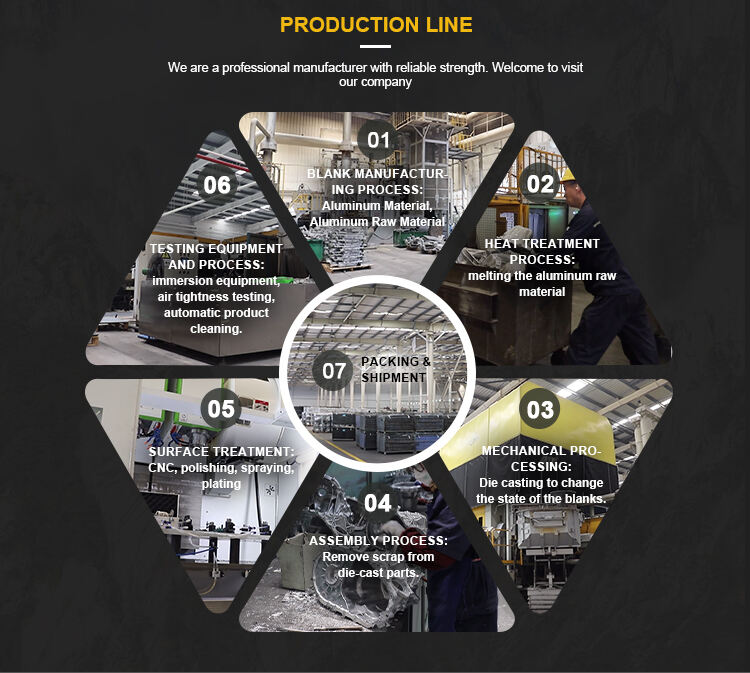

| 1, Technical advantage |

1, die casting industry experts more than 20 people, mold professional engineers more than 80 people; 2, 3D design, mold flow analysis, mold manufacturing, die casting process analysis(customized service) |

| 2, Quality monitoring advantage | 1, more than 10 quality engineers, special quality control team; 2, the number of testing equipment 10; 3, certification: ISO9001: 2008 international quality certification systen; ISO14001: 2004 system certification; ISO/TS16949: 2002 Automotive industry quality system certification; |

| 3, Advantages of mold manufacturing | 1, mold design engineer, can PRO-E, VG and other software; 2, advanced equipment, HAAS machining center, gantry CNC, etc., more than 49 equipments, an annual output of 300 sets of die casting mold; 3, can design molds for customers(provide customized services) |

| 4, Die casting manufacturing advantages |

1, 57 sets of production lines, with an annual capacity of 50000 tons of aluminum alloy die-casting parts; 2, intelligent production level: automatic soup machine, automatic spray machine, automatic pick-up machine, automatic transmission belt, high pressure point cooling machine, cutting and shaping equipment; |

| 5, Machine plus manufacturing advantage | 1, more than 600 sets of CNC machining machines and more than 60 sets of horizontal machining centers; 2, CNC machining programming engineers a total of 30 people, 30 project engineering and technical personnel; |

| 6, Surface treatment technology advantages |

1, independent spray plating supporting enterprises; 3, complete spraying and electroplating testing equipment; |

| 7, Supporting facility |

1, clean workshop: 1000 square meters GP12 clean workshop; 2, product monitoring station; 3, air tightness testing equipment; 4, infiltration equipment; 5, product automatic cleaning machine; |

Jincheng

Introducing the Custom High Precision Die Casting Aluminum Housing designed specifically for New Energy Vehicles. The product is manufactured by a well-known brand in the automotive industry.

Designed to meet up the demanding needs of modern-day electric vehicles. The aluminum housing is made to be highly durable and resist extreme temperatures making it ideal for harsh operating conditions.

Created to ensure that the motor other critical components operate at a temperature is optimal. It is prepared with a high-precision process is die-casting enhances the overall quality making sure the housing is suitable for use in high-performance applications.

Created to be economical supplying a dependable and solution is efficient automobile manufacturers looking to reduce production costs while keeping top-quality standards.

The product is easy to install which makes it perfect for both new and cars existing.

Designed to become very stylish having a design is minimalistic blends seamlessly with the vehicle's general design. The aluminum housing provides heat is very good which guarantees the longevity and dependability of vehicle elements.

Perfect to be used in numerous applications automotive. It can be utilized for electric power steering battery management systems and other vehicle is critical.

Environmentally friendly because it is produced from recycled aluminum. This makes it an option is great vehicle manufacturers looking to reduce their carbon impact and meet industry standards on sustainability.

The Custom High Precision Die Casting Aluminum Housing for Integrated Motor Controller New Energy Vehicles Heatsink Box is an excellent addition to any electric vehicle. It offers a reliable efficient solution for maintaining the optimal temperature for critical vehicle components all while being cost-effective and environmentally friendly. with Jincheng's reputation for high-quality this product is sure to exceed any customer's expectations.