How CNC manufacturing is used to produce a variety of products, from toys to cars to rockets. CNC manufacturing can be understood by this text.

What is CNC Manufacturing?

CNC means Computer Numerical Control. That means we program machines that create products with the help of computers. In CNC manufacturing, a computer drives tools such as drills and lathes to cut materials into a desired shape. This facilitates more accurate component and product manufacturing.

Various Categories of CNC Machines and Software

Many products are produced in CNC manufacturing using a variety of machines. Examples of popular machinetypes include CNC mills, CNC lathes and CNC routers. Such machines employ diverse tools to slice and mold elements such as metal, wood, and plastic.

These machines need specialised software to design the product and how the machine should create it. This allows a user to enter the size, shapes, and patterns of the product. Then the machine uses those instructions to create the end product.

How CNC Manufacturing Works

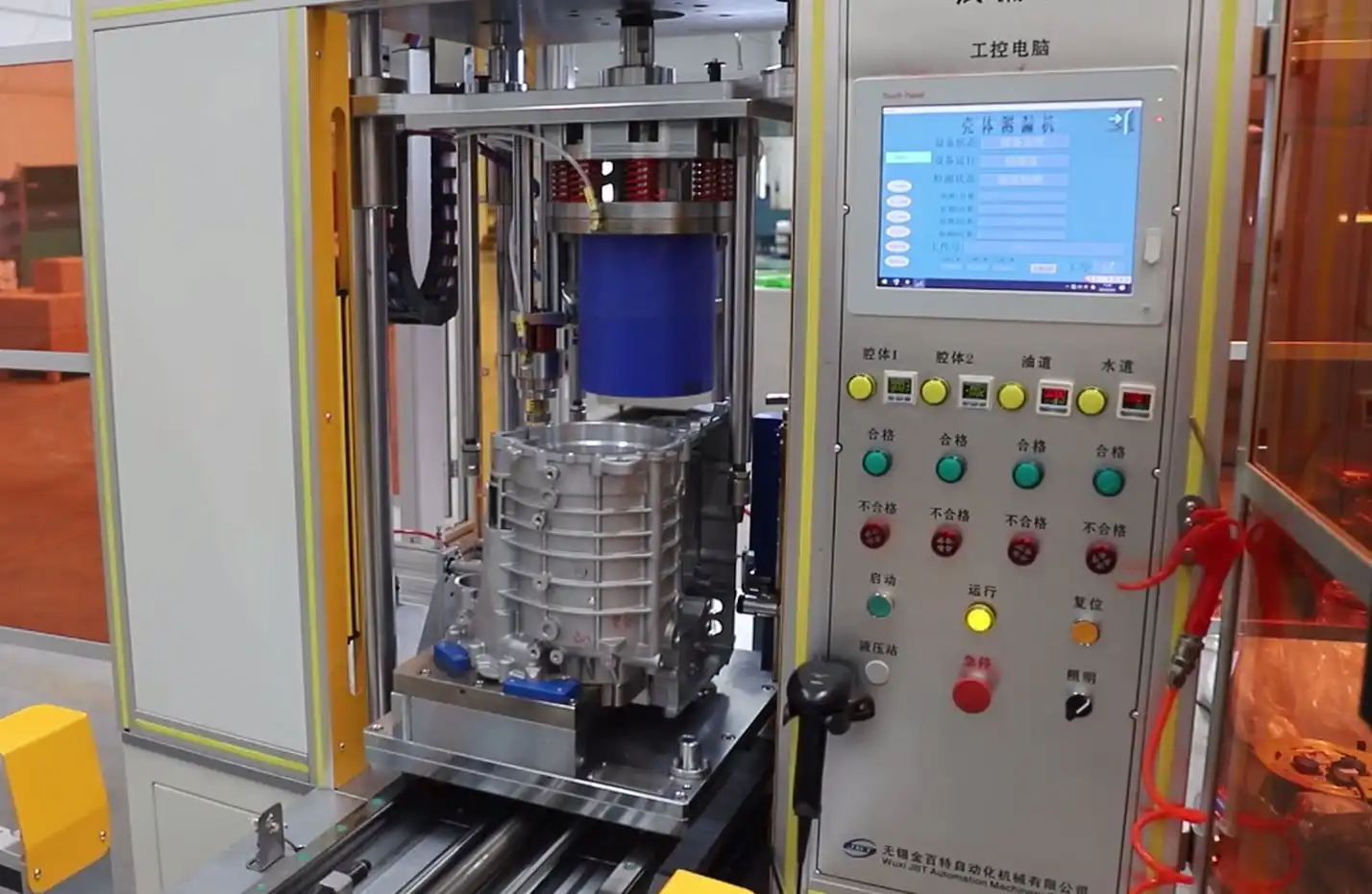

There are various steps in the product creation in cnc milling machine. It usually consists of several processes like milling, turning, drilling, and cutting. The process involves distinct tools at each stage to mold the substances into the end outcome.

The role of materials and tools in CNC Manufacturing

CNC manufacturing involves a variety of materials that require different tooling and processes. Common materials include aluminum and steel, plastic, and wood. Different material require different tools and speeds in order to shape them properly.

CNC Production: Tips for Safe and Efficient Machining

Safety and efficiency are key elements of the cnc engine block. Machines and tools need to be correctly configured to run efficiently, and they require maintenance to continue to function. Adhering to safety guidelines and wearing protective equipment are also key to preventing accidents.

CNC manufacturing is a fascinating subject that uses computers to drive machines to create products. cnc lathe includes machine, software, process, material, safety tips, etc., that a very basic understanding of CNC manufacturing can tell you about this industry. Happy learning!

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

KA

KA

BN

BN

LA

LA

MY

MY