Integration of precision casting + machining: provide one-stop solution from casting to subsequent CNC finishing, reduce supply chain management costs and improve delivery efficiency.

1. Die casting industry experts more than 20 people, mold professional engineers more than 80 people;

2. 3D design, mold flow analysis, mold manufacturing, die casting process analysis (customized service)

1.More than 10 quality engineers, special quality control team;

2.The number of testing equipment 10;

3.Certification: ISO9001:2008 international quality certification system; ISO14001:2004 system certification; ISO/ TS16949:2002 Automotive industry quality system certification

1.Mold design engineer, can PRO-E, VG and other software;

2.Advanced equipment, HAAS machining center, gantry CNC, etc., more than 49 equipment, an annual output of 300 sets of die casting mold;

3.Can design molds for customers (provide customized services)

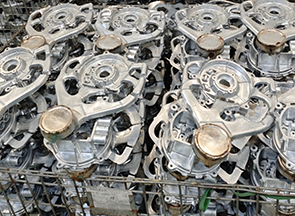

1.57 sets of production lines, with an annual capacity of 50,000 tons of aluminum alloy die-casting parts;

2.Iintelligent production level: automatic soup machine, automatic spray machine, automatic pick-up machine, automatic transmission belt, high pressure point cooling machine, ultra-high vacuum machine, die temperature machine, cutting and shaping equipment;

3.Flexible product design, to provide production solutions, to provide conditions for small batch production

1.More than 600 sets of CNC machining machines and more than 60 sets of horizontal machining centers;

2.CNC machining programming engineers a total of 30 people, 30 project engineering and technical personnel

1.Independent spray plating supporting enterprises;

2.One hundred thousand dust-free spraying workshop, three spraying lines, twelve imported electrostatic spraying guns, four automatic plating production lines, two pre-treatment production lines;

3.Complete spraying and electroplating testing equipment

Commonly used aluminum alloys are **ADC12, A380, A356, 6061, 6063 and so on.

Refining agent: such as Ti-B, Al-Ti-B alloy

Detergent: e.g. Sr, Na

Alloying elements: silicon , copper, magnesium, zinc, iron, etc;

(1) aluminum alloy

Common models: 6061, 6063, 7075, 5052, 2024, ADC12 (die-casting aluminum) and so on.

(2) stainless steel

Common models: 304, 316, 316L, 420, 430, 17-4PH, etc.

(3) Carbon and alloy steel

Common models: 1018, 1045, 4140, A36, 40Cr, 20CrMo, 45# steel, etc.

(4) Copper and copper alloy

Common models: H59, H62 (brass), T2 (copper), C11000, C17200 (beryllium copper)

(5) Titanium alloy

Common models: TC4 (Ti-6Al-4V), TA2, TB5 and so on.

(6) Magnesium alloy

Common models: AZ31B, AZ91D, etc.

(1) Engineering plastics

POM, ABS, PC, PA, PEEK

(2) Soft plastics

PTFE, PP

Integration of precision casting + machining: provide one-stop solution from casting to subsequent CNC finishing, reduce supply chain management costs and improve delivery efficiency.

High-precision machining: adopting advanced CNC equipment, it can meet the requirement of ±0.01mm or even higher machining precision, which is suitable for high-end manufacturing field.

Equipped with: high-pressure casting, low-pressure casting, sand casting, lost wax casting and other casting processes, we can choose the most suitable program according to the demand.

Equipped with: five-axis CNC machining centers, CNC lathes, milling machines, grinding machines and other equipment to ensure high-precision processing of complex parts.

Can process: aluminum alloy, stainless steel, carbon steel, copper alloy, titanium alloy and other materials for different application scenarios.

We provide aluminum alloy die-casting (such as ADC12, A356, A380), stainless steel precision casting (such as 304, 316) and other material choices to meet the needs of high strength and corrosion resistance.

Passed: ISO 9001, IATF 16949 and other quality management system certification, to ensure that the products comply with international standards.

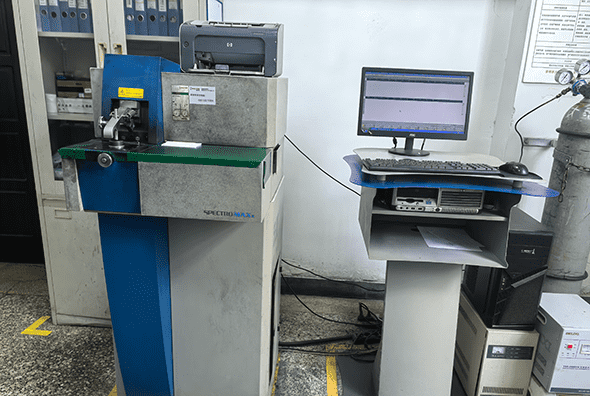

Adopting: X-ray inspection, coordinate measurement (CMM), spectral analysis, tensile testing and other quality inspection methods to strictly control product quality.

Combined with precision casting + CNC machining, it reduces material waste and improves production efficiency, thus reducing the unit cost.

The production base is located in Suzhou, enjoying the industrial chain and logistics advantage of the Yangtze River Delta region, which can provide competitive price and fast delivery.

Located in the Yangtze River Delta region with convenient transportation, we can respond quickly to domestic and international order demands.

With stable raw material suppliers and mature production management system to ensure stable and reliable delivery cycle.

Automotive parts: engine cases, gearbox components, brackets, etc.

Aerospace: high-strength aluminum alloy structural parts, stainless steel precision parts

Medical devices; surgical tools, implant stents, instrument parts

Electronic equipment: 5G base station heat sinks, laptop brackets, intelligent hardware shells

Industrial machinery: hydraulic valve body, pump body, automation equipment parts

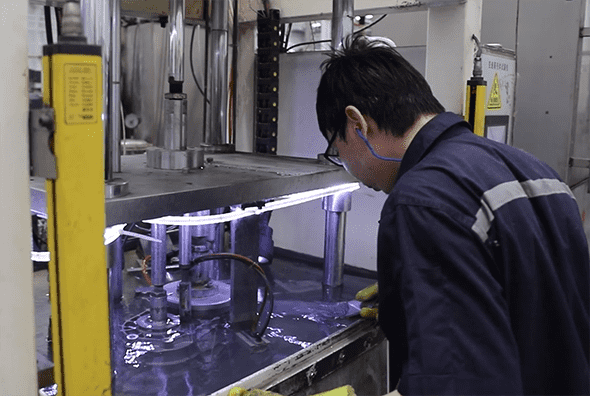

Airtightness testing equipment for die-casting aluminum alloy auto parts is an important link to ensure product safety, improve quality, increase production efficiency and meet regulatory requirements, which is of great significance to enhance the overall performance of the car and user safety experience.

Material spectrometer in aluminum alloy die-casting process not only helps to improve production efficiency and casting quality, but also can stabilize the process, is a die-casting plant must have an important testing equipment.

Coordinate inspection in aluminum alloy die-casting process plays a role in precision control and quality assurance, help to improve product accuracy, reduce defects, optimize the process.

Salt spray test plays an important role of quality control and performance verification in aluminum alloy die-casting process, which helps to improve the corrosion resistance of castings, extend service life, reduce failure rate, so as to ensure the reliability and stability of the products in the complex environment.

Hardness test in aluminum alloy die casting process can effectively assess the mechanical properties of castings, quality stability and surface treatment effect, to optimize the process and improve product quality to provide key data support.

X-ray nondestructive testing is a commonly used nondestructive testing technique, especially suitable for die casting quality inspection.X-ray nondestructive testing penetrates the material through X-rays and generates an image of the internal structure, thus detecting potential defects.