2024-11-04

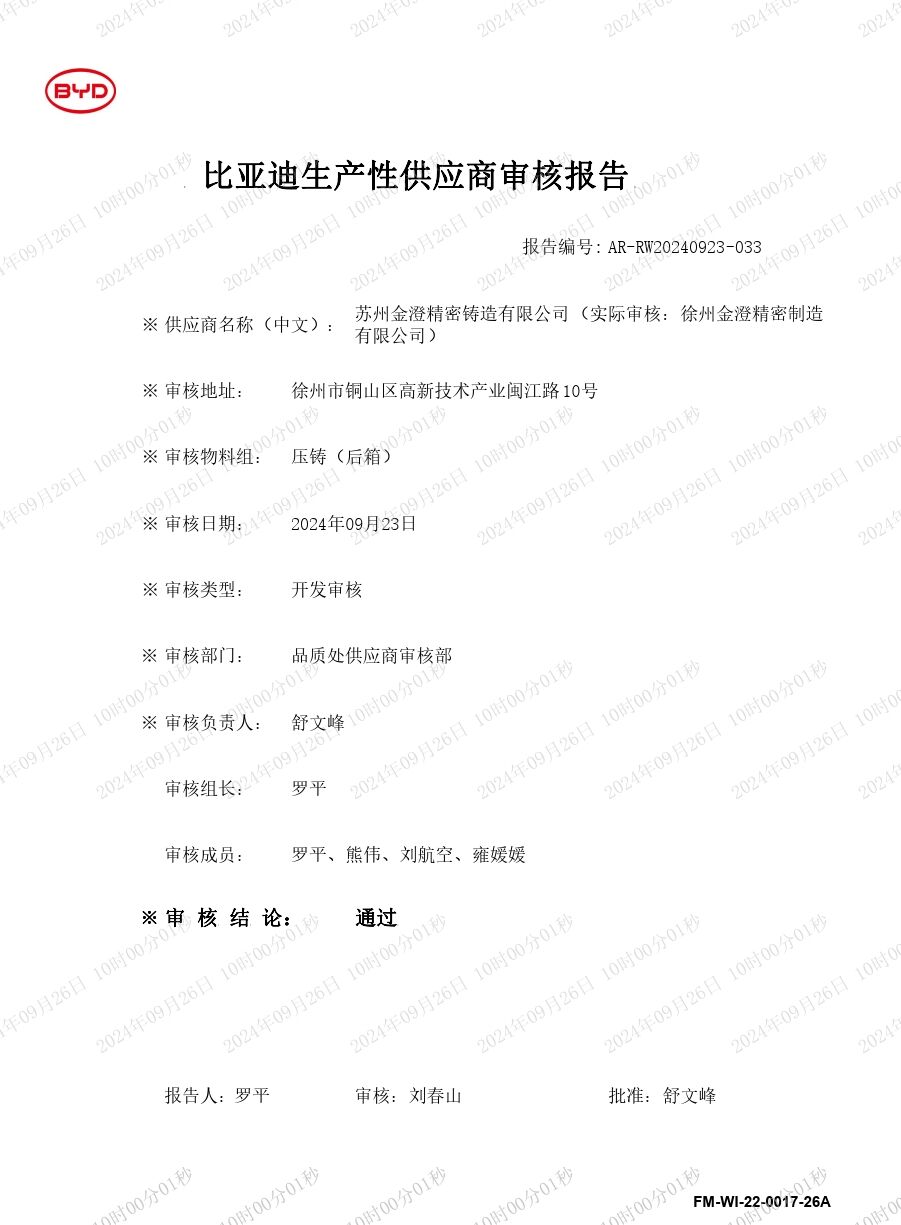

Suzhou Jincheng Precision Die Casting Co., Ltd. cooperates with BYD in aluminium alloy die-casting backboxes to meet the demand for lightweight and high-strength materials in the new energy vehicle industry. With its advanced aluminium alloy die-casting technology and strong production capacity, Jincheng Precision has become one of the important parts suppliers in BYD's supply chain. The cooperation mainly involves the production of high-performance aluminium alloy rear box components, which are crucial for vehicle weight reduction, energy efficiency and range extension.

JC Precision has an annual production capacity of 50,000 tons of aluminium alloy die casting, and the plant is equipped with multiple fully automated die casting islands and precision machining centres to efficiently support mass production. The cooperation between the two companies further strengthens BYD's competitiveness in the field of new energy vehicles, and also demonstrates JCPC's technological strength and innovation capability. These high-strength aluminium alloy components are optimally designed and precision die-cast with high structural strength and durability, meeting the strict market requirements for high-performance aluminium alloy materials. Through the cooperation with BYD, JCP can further deepen the layout in the automobile industry, promote the localisation process of new energy automobile parts and accelerate industrial upgrading and technological innovation.