Die casting aluminum and plaques/fwlink. icoAluminum die-casting is a fascinating process that uses melted aluminum to form a variety of objects. Reputation: They are fast, easy to produce and withstanding processes. In this post, we will have an insight into the various advantages and applications of aluminum die casting along with some ways to improve its quality and efficacy. False

Aluminum die casting is basically the process in which aluminum parts are manufactured by melting aluminum into molds. Turning the aluminum into molten state and then pressurizing it ensures that every nook and cranny in our mold will be filled by metal without any gaps. After the aluminum cools and hardens it is then removed from its mold, to be used for a variety of purposes.

Aluminum Die Casting Provides A Multitude of Benefits In The Manufacturing Sector:-

There are plenty of benefits that the industries enjoy from using aluminum die casting in manufacturing. For one, it is an accelerated approach to producing some parts. It also creates parts that are strong and durable. One other significant benefit is its ability to generate parts that are various shapes and sizes. Additionally, aluminum die casting is more affordable in terms of cost that appeals to manufacturers seeking to streamline their expenditures.

Aluminum die casting is versatile and can be used in many different fields. It is commonly used for manufacturing automotive, marine and aircraft parts. Moreover, occurs in the electronics field too but being that its used to produce components for gadgets such as computers and cell phones. Another sector that finds usefulness in aluminum die casting is the construction industry where it helps to fabricate parts for a multitude of structures.

A variety of methods used by manufacturers which can greatly improve the quality and productivity of aluminum die casting. The use of top notch molds is the first and most important step towards reliable, repeatable part production. Similarly, it is important to use high-quality aluminum alloys that are friendly for die casting. Manufacturers should calibrate and maintain their equipment, while also constantly training their workforce on how to properly use the various types of equipment at play.

Aluminum die casting Part1 - selection of aluminum alloy The other types features have there own specification for alloy which is being place as per the lot of forces acting upon. While some alloys are stronger and others offer increased corrosion resistance. Both the intended application of these parts and the types of structures they will be supporting are crucial in determining what type is used.

In a nutshell, aluminum die casting happens to be an extensively conducted process within manufacturing for rapidly forming strong as well as durable parts. Its benefits, such as affordability, ability to produce high quality upscale parts and the potential to build a wide variety of different components have made this method popular among manufacturers. The quality of this operation can be improved significantly by the selection of better molds, aluminum alloy materials, equipments and staff that are properly trained for use. Choosing the right aluminum alloy for your die casting application ensures that you get parts which are perfectly optimized to your use.

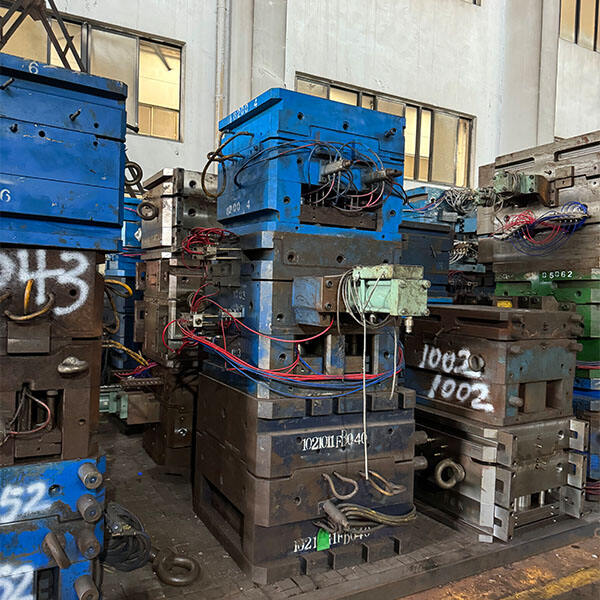

7 aluminum die casting procedure, technical support, quality inspection, mold making die-casting production, production of machines, processing of surfaces, as well as other facilities. Our company owns 150 - 4000 tons of fully-automated cold chamber die-casting island production line 60, high-precision machine centers that are more than 600. The company also includes ancillary facilities as well as numerous large-scale precision measurement equipment and instruments. They have the capacity of 50,000 tons of aluminum alloy parts for die-casting as well as parts research and development production, as well as precision processing capabilities, to attain the benefits of production on a large scale.

In 2006, our business was established in the year 2006. We are aluminum die casting in die-casting aluminum alloy pieces as well as precision machining and general industrial components. We provide online human service all day, every day. We also communicate in a variety of languages. We can also offer a team of service representatives to work with your project.

All of our products are produced at the facilities of the aluminum die casting they belong to. We provide all the information on pricing, from raw materials through production and services. The company is equipped with more than 20 die-casting industry experts and more than 80 mold professionals engineers. We offer molds and production solutions for our clients. Our product design is flexible. It can be used in small-batch production.

We have our own 3 aluminum die casting production facilities, Weitang auto parts casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant; the total assets have surpassed 1 billion yuan and covers the area of almost 300 acres and a plant area of 180,000 square meters. The company is equipped with more than 600 CNC machines with more than 60 vertical machining centers and complete electroplating and spraying equipment. We're committed to providing customers with professional precision machining, customized services.