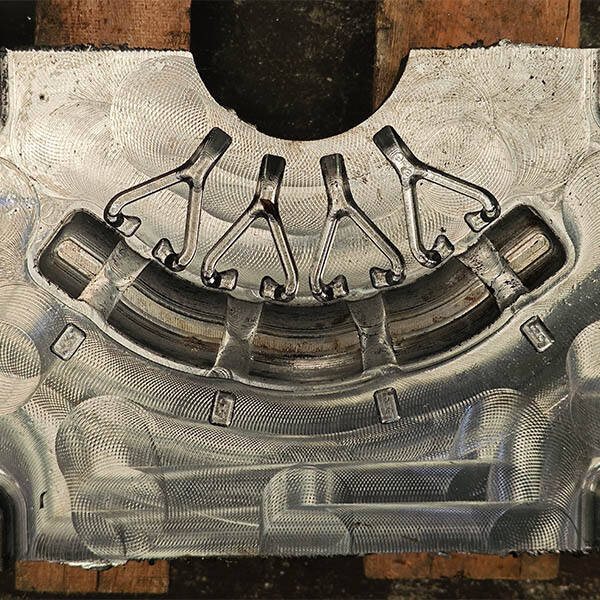

The engine block, also known as a cylinder block (above), is perhaps the most elemental part of an automobile and it houses almost everything required for its proper operation. The way that this framework surrounds all of what you write is like as a solid shell keeping it rigid.

Underneath the hood, you have cylinders, pistons and a crankshaft. Together, these components play a part in ensuring the engine works smoothly. Cylinders function as smaller channels where fuel is ignited for the energy build. The pistons slide up and down within the cylinders, with a crankshaft helping to turn that vertical movement into forward motion.

Different materials are there when it came to manufacturing an automobile engine block, each comes with a few pros and cons. For example, iron blocks are used in many engine applications given its strength and durability. But iron blocks are usually heavy, and they can have a deleterious effect on fuel efficiency.

Alternatively, there are also aluminum engine blocks that weigh significantly less than iron ones. While aluminum may be lighter and allow for better fuel mileage over iron, it is not as strong, which could lead to cracking or warping.

The gods of car manufacturing have to balance the benefits and drawbacks of each material when building their engines. It needs to withstand the heat and pressure of running a car, but it also must be as light for weight savings to satisfy efficiency targets.

Engine blocks can develop a number of issues over time from wear and tear or normal usage. They can develop cracks in the block - which is essentially a metal housing that encases an engine's innards or oil and coolant leaks. The block can also become warped as a result of overheating or other conditions leading to perhaps loss of power, rough engine operation, etc.

In order to do so, the mechanics have a long look at the block and decide what is best. Replacement, in other cases a special repair technique known as "welding" can be used. "

7 production process, technical support, quality inspection, mold making die casting production, machine production surface treatment, and supporting facilities. Our company has automobile engine block machining centers, completely automatic cold chamber island die-casting production lines ranging from 150 - 4000 tons. The company also has various ancillary facilities and numerous large-scale precision measurement equipment and instruments, with an annual production of 50,000 tons of aluminum alloy die casting parts and parts research and development production and precision processing capabilities to get the impact of large-scale production.

Our company was established in 2006. was founded. We are specialized in die-casting aluminum alloys as well as precision machining and automobile engine block components. We support 24-hour human online support and communications with minorities in a variety of languages. Additionally, we have the service team to help with the project.

We have three production facilities: Weitang auto part automobile engine block, Suzhou Jincheng Precision Casting Plant, Xuzhou Jincheng Precision Casting Plant. The total assets of the company exceed 1 billion Yuan and covers an area of 300 acres. Our facility covers 180,000 square metres. The company boasts over 600 CNC machines with 60 horizontal machining centers as well as complete electroplating and spraying testing equipment. We're committed to supplying our customers with high-quality custom machining services.

All automobile engine block are manufactured at the facilities of their respective companies. From the purchase of raw materials to further processing and production services, we have detailed price information. Our company has more than 20 experts in the field of die-casting and more than 80 mold expert engineers. We can provide molds and production solutions to our customers. Our product design is customizable. It can provide conditions for small-scale production.