Bro also used cnc vac machines Brotools You are looking for the best toolmakers to your help in factories, so people these tools but inside Factories barely lessly know what they do She made things easy. They are so crucial because they have the ability to churn code out quickly and correctly. As a result, this allows for the products created by these machines to be of quality. What is the full form of CNC & VMC: Full-Form!! In order to understand what these terms mean, we need knowledge of how a machine functions.

Choosing the right tools and ways to get work done is a crucial part of extracting maximum benefits from CNC & VMC machines. Since these are highly accurate machines they can cut very precise. Quality product: A quality product is built when workers are using the right tools and method to build it. If, for instance a factory has to make many of the same item having the right techniques means that you can produce those items well and consistently.

CNC as well a VMC machines are very powerful tools and they can do amazing things. Their activity is supported by a computer programme setting the paths and operation of cutter heads. These machines can produce complex shapes and high speed cuts with this technology. If you decide to use these machines, your factory will certainly be able to increase its total productivity since the process of doing work with them is incredibly efficient. What this does, however is speed up mass production, boosting businesses.

There are several important benefits of using CNC and VMC machines in manufacturing. The main advantage, that is they can able to produce the products at both fast and accuracy manner. For businesses, this could be truly beneficial as it enables company to produce more items and respond quickly on their customers' order. In addition to that, the use of these machines also helps in minimizing waste during production. Big/heavy machines tend to have more precision than smaller ones, leading to better and tighter cuts/shapes that would allow for less waste of material.

These CNC and VMC machines are using highly advanced types of technology, which makes these tools able to perform operations for them. They depend upon computer programs to govern the path of the cutting tools. The machines are able to create cuts and shapes so fine they would be impossible by hand. These machines also are equipped with a feature to remember and hold programs. Once you create a program, you can use it as many times in the future: this saves time and minimizes human errors during production.

In 2006, our company was founded. We are specialized in die-casting aluminum alloy components in precision machining as well as general industrial parts. We provide online human service cnc and vmc machine and communicate in minorities languages. We also can provide a service team for your project.

cnc and vmc machine of our production sites: Weitang auto part casting plant, Suzhou Jincheng Precision Casting Plant, Xuzhou Jincheng Precision Casting Plant. The total assets are more than 1 billion Yuan and covers 300 acres. The plant is spread over 180,000 square meters. The company boasts over 600 CNC machines and 60 horizontal machining centers as well as complete electroplating and spraying testing equipment. We're committed to supplying customers with professional precision machining and customized services.

All of our products are produced at the facilities of the cnc and vmc machine they belong to. We provide all the information on pricing, from raw materials through production and services. The company is equipped with more than 20 die-casting industry experts and more than 80 mold professionals engineers. We offer molds and production solutions for our clients. Our product design is flexible. It can be used in small-batch production.

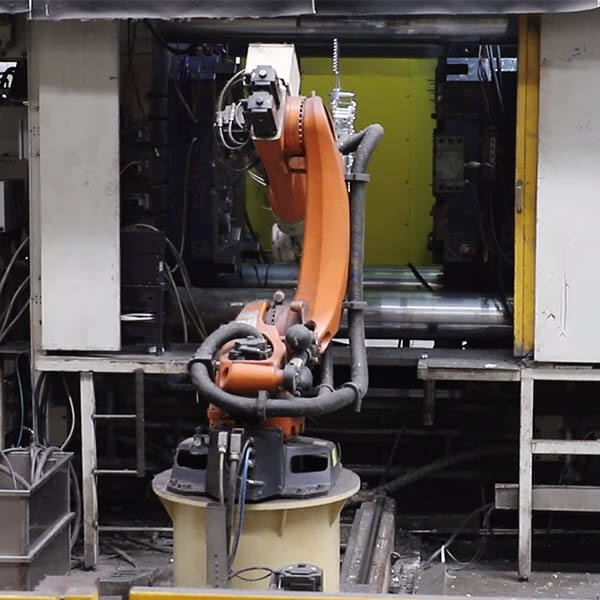

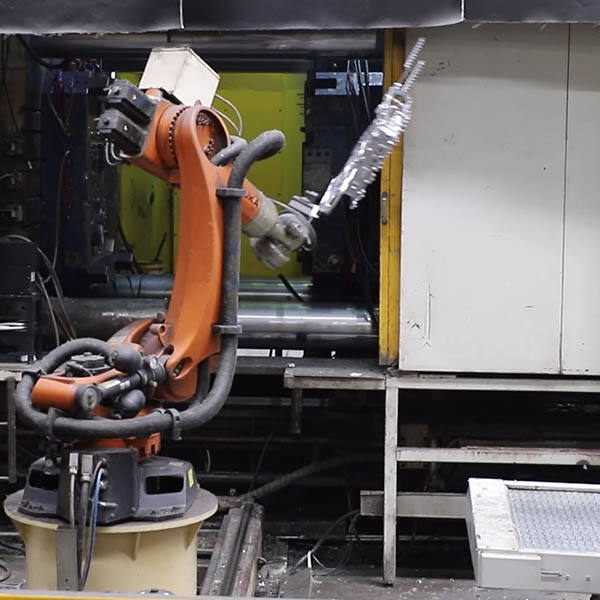

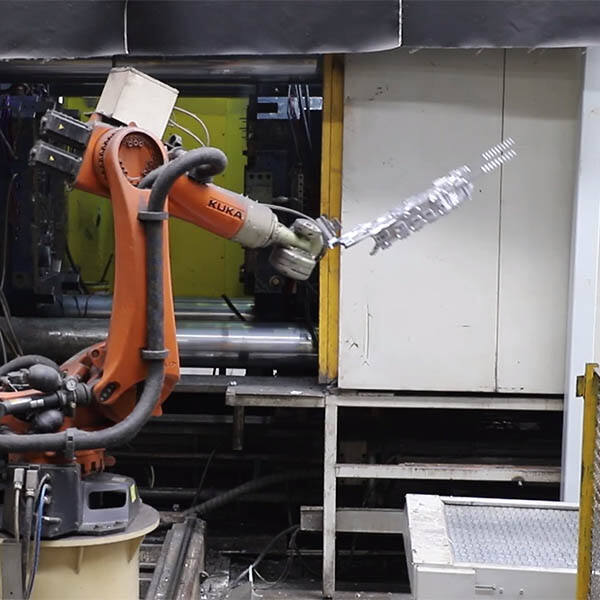

7 production process, technical support, quality control, mold production, die-casting production, machine production, processing of surfaces, as well as other facilities. Our company is equipped with 150 to 4000 tons of fully automated cold chamber die-casting island production lines 60, and advanced precision machines that exceed 600. Additionally, the company includes ancillary facilities as well as numerous large-scale precision measurement cnc and vmc machine and equipment, with an annual production of 50,000 tons of aluminum alloy die-casting components and research and development of parts, production and precision processing capabilities to get the impact of large-scale production.