Laser metal with some other kind of CNC method, and as this is a strong tool to make all type of Metal products. This technology is widely used in the field of metal fabrication. Thanks to new developments, CNC laser metal cutting has never been faster or more precise! Here we delve deeper into the process with CNC laser metal cutting and how this tool is something of an enigma to create a plethora of various styles made from all sorts metals.

CNC laser metal] is a cutting device that utilizes the latest technology of sharp, directed light from lasers which cut through flat-sheet materials such as sheet metal. The computer program controls a powerful laser, which can make precise cuts and form different shapes similarly precisely. The laser is then given a path to follow by the computer which then makes each cut.

One of the main advantages of CNC laser metal is that it can eliminate thick blocks of metals accurately and rapidly. This means it can cut both mild steel, which is easy to and cuts well, but also harder alloys that are much tougher. The variance of items which may be fabricated with CNC laser metal makes it an extremely useful tool in a large number of industries.

The first step is that a metal sheet on metallic moved platform which typically cut bed. The purpose of this bed is to keep the metal sheet safely in place during cutting. Once you are ready with the metal piece, a digital representation of the mould is created by virtue of computer program. This digital picture is used as a model of cutting the metal by laser.

As compared to the traditional metal cutting methods, there are several advantages of CNC laser metal cutting. For starters, it is many times more precise as well. This extremely accurate precision means that the metal parts can be produced with a high level of quality control over its size and shape. So it is no waste and surprises given every thing Is made of such perfection.

On the other hand, CNC laser metal cutting takes less time than traditional ways for second difference. The laser is a fast cutting tool and can cut through thick metal, so this reduces how long each product stays in the manufacturing process. The result of this is businesses can create more products in a lesser period which will help them to keep up with the customer demands.

CNC laser metal cutting is applied to various projects and industries For instance, it works tremendously in component production throughout the land of industrial machinery since exactitude and quality are highly expected. It is also very popular for producing metal signs and logos throughout shops, houses as well as decorative metal artwork that can be displayed in homes or galleries.

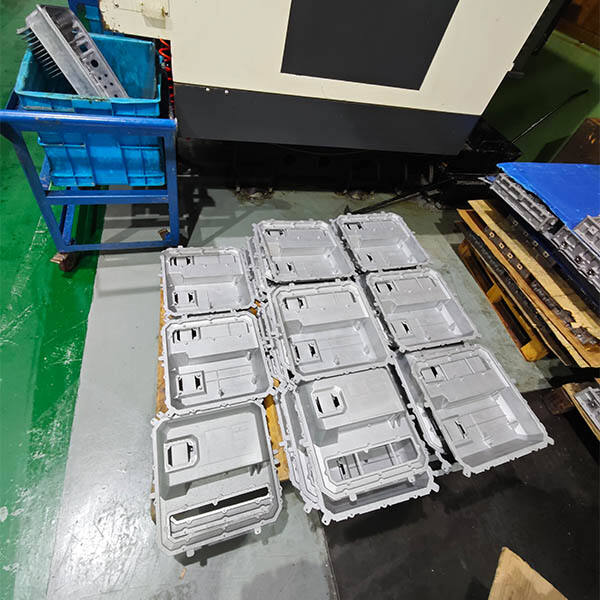

7 production process, technical support, quality control, mold production, die-casting production, machine production, processing of surfaces, as well as other facilities. Our company is equipped with 150 to 4000 tons of fully automated cold chamber die-casting island production lines 60, and advanced precision machines that exceed 600. Additionally, the company includes ancillary facilities as well as numerous large-scale precision measurement cnc laser metal and equipment, with an annual production of 50,000 tons of aluminum alloy die-casting components and research and development of parts, production and precision processing capabilities to get the impact of large-scale production.

The goods are made in their own factories. We provide all the information regarding prices, from raw materials through production and services. More than cnc laser metal expert mold engineers and 20 experts in die casting are on hand at the firm. We can supply molds as well as production solutions for our customers. Our product design is flexible. It can provide conditions to produce small batches.

We own three main production centers Weitang auto parts casting plant Suzhou Jincheng precision casting plant cnc laser metal precision casting plant The total value of the assets is more than 1 billion yuan covers the area of almost 300 acres with a total area of 180 000 square meters The company has more than 600 CNC machines including 60 horizontal machining centres with complete electroplating spraying and testing equipment We are committed to providing our customers with high-quality precision machining and customized services

Our company was established in 2006. was founded. We specialize in die-casting aluminum alloys as well as cnc laser metal machining and general industrial components. We provide human-powered online service throughout the day, and communicate in languages of minorities. We also have the service team to help with a project.