CNC machining services are essential for creating parts and pieces that require an extremely high level of precision. These systems use computer controlled machines designed to get everything perfect. CNC: The full form of CNC is Computer Numerical Control. It indicates machines that are directed by a code from a computer. Their sizes and shapes vary as CNC machines come in many different varieties. These machines are capable to produce everything from the smallest parts for toys, up towards large and complex forms of airplane pieces.

CNC machining is known for its accuracy and quality. Since these machines are computer-controlled they make parts that auto fit into every detail of your plan. The machines are able to cut, drill and laser a large range of materials down to the sizes programmed into our computer. This high level of accuracy is crucial in manufacturing highly specialised parts for industries, such as aerospace, medical and automobile sectors where the correctness if dimensions must be maintained to ensure safety and functionality.

The availability of CNC machining has made it easy to develop physical, mechanical prototypes for the individual components. In the recent years itself, there have been a lot of improvisation in technology concerning CNC machine tools. All these feature enhancements have made CNC machining even more ideally suited for parts manufacturing across a wide array of industries. These machines are precise as well other important operations including milling, drilling and turning. In doing so, they enable manufacturers to increase their output and cut production times considerably. This flexibility gives businesses the upper hand in responding to market demands.

CNC machining services help to ensure that high-quality parts are produced. By using CNC machines, manufacturers can create parts that comply with industry requirements set forth by the government. In many sectors - including the aerospace, automotive and medical industries -- the need for high-quality parts is paramount to safety dependability and performance. Through the use of CNC machining services for example businesses can guarantee that their products match what they are expected to be made up of and will perform as required.

Every industry is in need of CNC machining services, whatever the case expense and how much odd or difficult a project tend to be. They use the latest CNC technology to develop precise parts and components quickly. From custom parts for small businesses, to large production runs needed by big companies, CNC machining services are crucial in the realm of modern manufacturing. These standards ensure that each product is made completely; perfect.

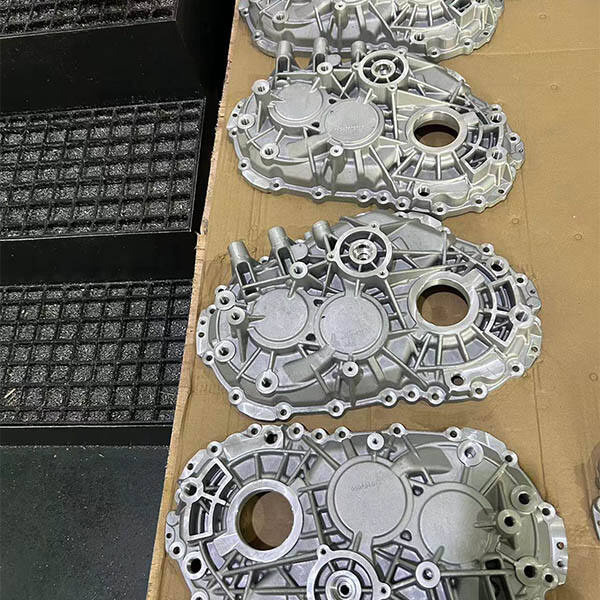

The product is manufactured in the company's own facilities. From purchasing raw materials to subsequent production and processing services We provide detailed pricing details. More than 80 expert mold engineers as well as 20 experts in die-casting are on hand at the firm. Our design for products is flexible and we are able to design molds to meet the needs of our customers, and also provide cnc machining service. It can provide conditions to produce small batches.

In 2006, our business was established in the year cnc machining service. We specialize in die-casting aluminum alloy components as well as precision machining and general industrial components. We offer 24 hours of human-to-human online service as well as communication with minorities in a variety of languages. We also have a service team to connect with a project.

We own three main production centers Weitang auto parts casting plant Suzhou Jincheng precision casting plant cnc machining service precision casting plant The total value of the assets is more than 1 billion yuan covers the area of almost 300 acres with a total area of 180 000 square meters The company has more than 600 CNC machines including 60 horizontal machining centres with complete electroplating spraying and testing equipment We are committed to providing our customers with high-quality precision machining and customized services

The seven processes of production are tech support, quality control, cnc machining service casting, die-casting and surface treatment. Our company has 150 - 4000 tons of fully-automated cold chamber die-casting islands production line 60, high-precision machines that exceed 600. It also has dozens of large precision measuring equipment and instruments, along with a range of other ancillary services. The annual production of the company is 50,000 tons and it's able to do precision manufacturing and processing.