A die cast mold is an indispensable manufacturing tool that helps crank out identical shapes such as toy cars or metal parts at a scale and coherence unmatched by other methods. To do that, the best scientists as possible worked out a mould which is an imitation of future object. Finally, the melt is poured into the mold maintained at an elevated temperature As a consequence of cooling and material solidification on cavity surfaces which determine casting shape there results shaped part made out of metal. When it comes to crafting the die cast mold, some crucial considerations should be taken into account such as ensuring under what temperature metal has melted and based on which size can a proper-sized piece must be molded. The mold needs to also be sturdy enough so it does not break when the hot metal is pressed into. A good die cast mold designer and maker needs to master a great deal of professional theory information and also requires a precise scale.

Due to modern advancements, it has become easier than ever before to create high-quality die cast molds. One process is to use computer applications for creating accurate shapes in molds. Additionally, a move to advanced metals with greater strength and durability has been widespread. Others have gone so far as to use 3D printers for mold fabrication - an idea that, collectively explained, means the direct digital printing of molds from a computer. This demonstrates a refinement in the process of making die cast molds.

Even though die cast molds are sized to last a long time before they need repair or replacement, regular maintenance should be performed after your mold is up and running by an experienced professional. Functionality experts also point out the importance of deep cleaning and a recommended treatment with Lustre struts to protect against damage through metal contact adhesion. Mold needs to be maintained regularly, and if it has problems then timely repairs are really important. Carefully tending to these molds can assure manufacturer cost savings, and the manufacturing of endless items both quickly.

Use of latest technology and that too in efficient machinery has the potential to increase production considerably thus increasing profits for a company. A tactic for enhancing production efficiency is the use of multi-cavity machines that can produce several molds at one time. Furthermore, the incorporation of robotic systems to pick parts from molds accelerates this procedure immensely, increasing efficiency and accuracy. Through the use of best-in-breed technology, manufacturers can drive both operational excellence and their bottom line.

Die cast molding is really quite important to the manufacturing sector, as it makes possible for a very quick and cost effective production of identical products. Sophisticated technology, combined with keeping high molds maintenance standards helps manufacturers achieve the best possible process optimization results and save costs while multiplying profits. You might even end up constructing your own unique design for a project using the latest in die cast mold technology!

We own three main production centers Weitang auto parts casting plant Suzhou Jincheng precision casting plant die cast mold precision casting plant The total value of the assets is more than 1 billion yuan covers the area of almost 300 acres with a total area of 180 000 square meters The company has more than 600 CNC machines including 60 horizontal machining centres with complete electroplating spraying and testing equipment We are committed to providing our customers with high-quality precision machining and customized services

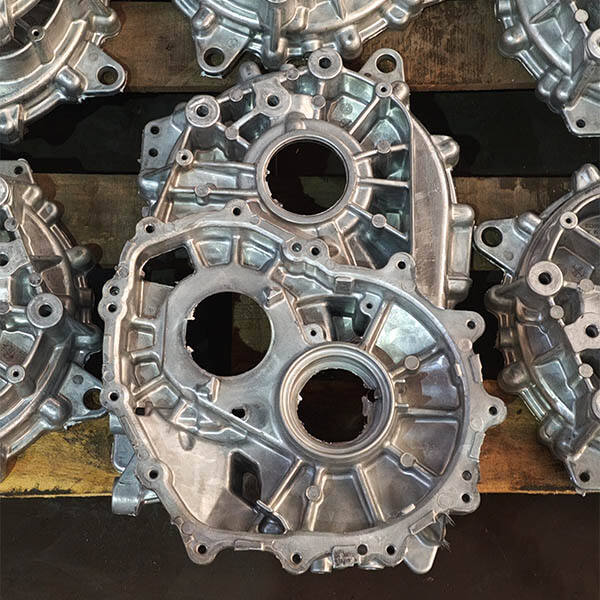

Our company was die cast mold in 2006, specializing in traditional cars, innovative energy vehicles, telecommunications inverter, photovoltaic energy storage rail transit, medical aviation, as well as other custom aluminum alloy die-casting components and precision machining and general industrial components. We support 24-hour human online support and communications in minority languages. We can also provide a service team to connect with a project.

7 production process, technical support quality control, mold production, die casting production, machine production, surface treatment process, supporting facilities. Our company is equipped with 60 modern precision machining centers and fully automated cold chamber island die-casting production lines ranging between 150 and 4000 tonnes. The company also has dozens of large precision instruments and measuring equipment, as well as various related services. The die cast mold production of the company is 50,000 tons, and it can perform precision manufacturing and processing.

The product is manufactured by their own factories. From the purchase of raw materials to further processing and production services we provide die cast mold details. The company is equipped with more than 20 experts in the field of die-casting and more than 80 mold professional engineers. Our product design is flexible, we can design molds for our customers and offer solutions for production. It will provide the right conditions to produce small batches.