Do you think what the benefits that die casting products can provide for your industry needs? So, phrase it some more. - the semantics Below are several reasons why they make an excellent option:

Fast and Accurate: The die casting products provide the best combination of speed with precision in their making. The manufacturing is so well thought out that wastage at minimal and the product vary little between each manufactured pack.

Unmatched Durability: Die casting products are manufactured by applying high pressure to shape molten metal current and die-elaborate cavities. It can only ensure that its product is significantly durable because it has been proven to resist high compression and extensive wear.

Customized to the Core- The best part about die casting products is their potential for customization. This range in shapes, sizes and colors makes them perfectly suitable to be custom-made according to your specific industrial needs.

The process of manufacturing die casting products may appear complicated, and we will simplify it for you to make things easier.

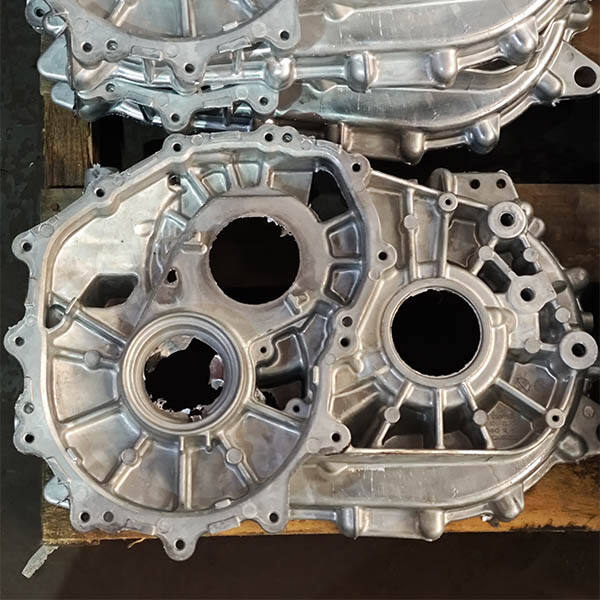

Making the Mold: The first step is to create a mold that acts as depending of things to come. These are made from steel and long lasting as used repeatedly.

Metal Melting - The chosen metal, zinc, aluminum and copper is needed to be melted in a furnace in order to make it molten enough for casting process.

Melt Injection in Mold: The obtained molten metal is further injected into the mold, under high pressure so that it adopts the shape of provided specification within a die. Thus, the metal is cooled and hardened perfectly in a similar shape.

Product Removal: The ultimate product is then pulled out from the mold by numerous methods (mechanical or hydraulic actions) following ample cooling of metal.

The Other End Of Die Casting Products - The Vesatility And Wide Range of Applications

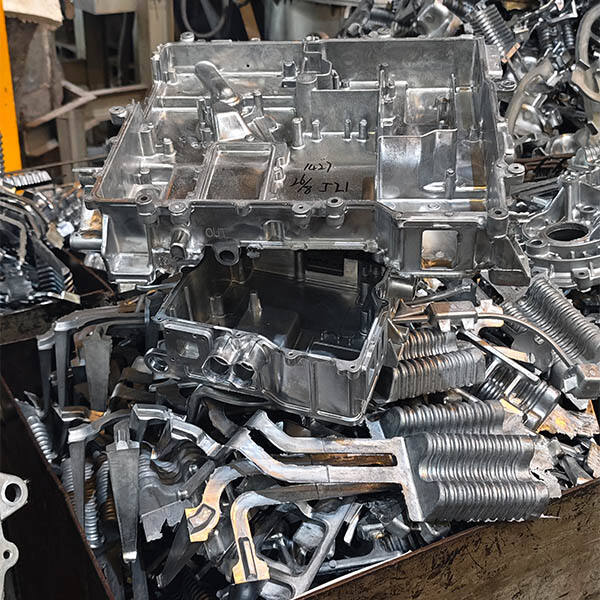

Die casting products are used a lot in many fields. Some examples include -

Automotive Industry: Die casting products are used for the production of a wide variety of parts on vehicles from engine components to structural elements.

Appliance manufacturing: Die casting is used heavily in the production of appliances such as refrigerators and washing machines

Electronic: Die casting is capable of producing housings for a large variety of electronic devices (Laptops, tablets, handsets) without compromising on the quality.

Selection of right kind of material is a critical decision and you need to weigh it up. Consider the following factors and do not NSNumber.

Strength Criteria: Different metals yield different strengths including hardness and malleability, the more however need a skillful at selection.

3) Corrosion Resistance: Operational environmental conditions for the product affects corrosion resistance, hence which metal to be chosen.

Recycled steel lessens cost as the prices of metals always vary and you are to ensure your choice of metal is based on a relatively manageable financial standpoint.

There are a few things to consider for evaluating the quality of die casting products;

Surface Finish:- A surface that is smooth and devoid of defects are reflective of the best quality.

Size & Fit: It is very important that the product meets dimension specifications.

Does the product reflect a strength: The frequency and method of its deployment in applications should be robust matching up to where it needs to perform.

To sum it up, die casting products thus make for an appealing prospect on a number of industrial fronts being both effective and durable as well having the ability to be customized. Understanding the manufacturing process, contemplating material selection and validating quality parameters are all critical steps in finding die casting product that best meets your requirements.

The product is manufactured in the company's own facilities. From purchasing raw materials to subsequent production and processing services We provide detailed pricing details. More than 80 expert mold engineers as well as 20 experts in die-casting are on hand at the firm. Our design for products is flexible and we are able to design molds to meet the needs of our customers, and also provide die casting products. It can provide conditions to produce small batches.

We have our own 3 important production facilities, Weitang auto parts casting plant, Suzhou Jincheng die casting products, Xuzhou Jincheng precision casting plant; the total value of the assets is more than 1 billion yuan, covers an area of nearly 300 acres, and has a plant space that is 180,000 square meters. The company has over 600 CNC machines with more than 60 vertical CNC machining centers, and a complete spraying, electroplating testing equipment. We offer professional precision machining services that are tailored for our clients.

In 2006, our business was established in the year die casting products. We specialize in die-casting aluminum alloy components as well as precision machining and general industrial components. We offer 24 hours of human-to-human online service as well as communication with minorities in a variety of languages. We also have a service team to connect with a project.

The 7 production processes are tech support, quality control, mold-making casting, die-casting and surface treatment. Our company boasts 150 - 4000 tons of fully automatic cold chamber die-casting island production lines 60, as well as advanced precision machine centers that are more than 600. The company also has dozens of large precision instruments and measuring equipment, along with a range of additional services. The annual production of the company is 50,000 tons, and it has the capability of die casting products precision manufacturing and processing.