Gearbox Housing: One of the most crucial parts in all machines Machines would be entirely unusable without it... that is if they work at all, right? These small parts of gearbox housing help the machines to do their work. In this paper, more insights on the gearbox housing will be shown alongside an explanation why our concept is so essential for mechanical designs. The gearbox housing is made up of many differently shaped sections. These parts are the gears, bearings and finally shafts. The gear is the moving part that gives motion to machine. This purpose is usually something to do with locomotion, thus these gears would rotate and as so serves this purpose of allowing the machine to carry out its function. The bearings are part of the mechanism that keeps everything working smoothly as they slide back and forth to move gears in a clean cut. Bearings cut down on friction which in turn allows the gears to continue spinning with no hiccups. Shafts are a material piece that connects these gears and make sure they work as planned. This Jincheng housing is designed to keep these pieces clean and prevent them from wearing our down. The gearbox house billet for the housing is mostly metal and it's plenty stout to do its job. This gearbox house acts as a cover that keeps out the dirt, dust and other particles from entering into gears, bearings and shaft. Cleanest as it may stay on the surrounding to operate all works with its efficiency. An in order to keep the remaining elements out of dust and debris as well as overspill an apparently essential housing which only ensures that all guts works inside. The machines, especially the ones in factories are at a high level of power and speed also use good gearbox housings. They all collaborate to where the machines would not randomly break down. Machinery breaking or becoming faulty can lead to production hold-ups because the latter are often what enable productivity. You will need strong hosing that can hold up to the pressure and not easily break down.

The tough cabinets endure the roughest environments from high temperature to heavy usage without damage. That promises to be the only use of a well-engineered gearbox housing: keep people out for repairs, which take both time and money. Good business in a way because it more work gets done with the least amount of time thanks to machines running smoothly out off teh bat.

Featured Video Gearbox housings need constant care to keep them functioning correctly. That Jincheng it includes washing the gearbox bell housing case outside and in, oiling moving parts / evaluating machine for continued use. Prevent small problems from becoming big ones with regular maintenance.

It does not seem at all good, when something is broken or barely done to come a craftsman / electric technician and fix energy it? In such cases, replacing a whole part of gear-box casing may be necessary to keep equipment working. Regular checks by a trained professional will detect potential problems early and fix them before they turn into very expensive issues.

Aluminum Aluminum, being as strong and versatile it is only weighing a few ounces; makes aluminum the material of choice for a wide range. However, it is not as hard or durable as iron or steel. Iron is tough and strong so these same treatment gears excel in this area too, the Jincheng high durability of iron also mean it well suits as casings for gearbox on heavy machinery. It gearbox housing is more commonly used because it can handle high temperatures, and withstands extra powerful and extremely effectively (in most industrial conditions), but only steel.

New gear box housing design and gels are being developed on the technological impro-vest. Newer-Stronger-Faster=Wear, Materials that can receive more stress or wear They clutch housing are even creating novel mechanisms capable of achieving superior performance over the traditional methods.

In the meantime, innovations in technology are making it easier to inspect and maintain gearbox housings. For example, sensors can be installed right on the transmission housing machinery to detect operation and catch a problem long before it gets large. With this proactive attitude protecting workers, preventing bottlenecks and keeping equipment running is a standard.

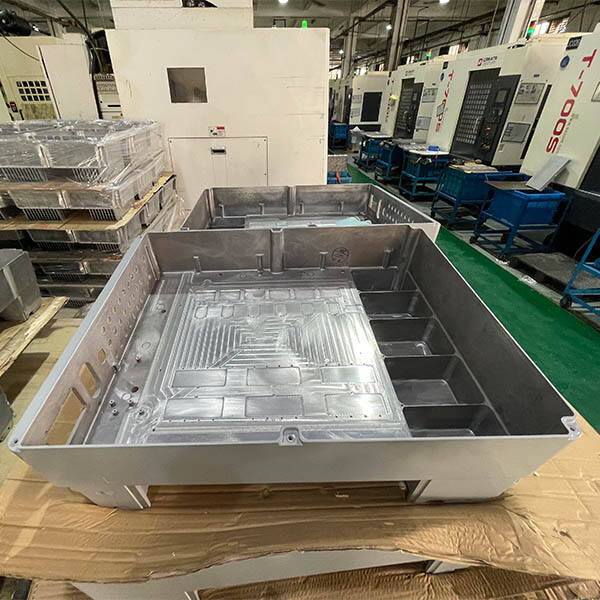

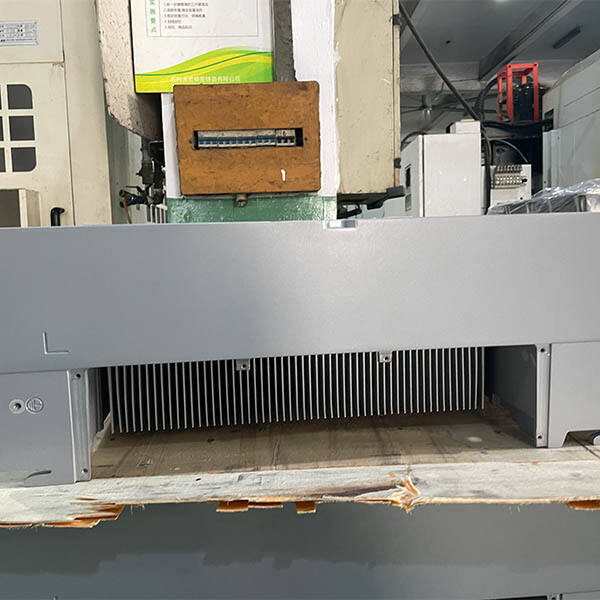

We have our own 3 Gearbox housings production facilities, Weitang auto parts casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant; the total assets have surpassed 1 billion yuan and covers the area of almost 300 acres and a plant area of 180,000 square meters. The company is equipped with more than 600 CNC machines with more than 60 vertical machining centers and complete electroplating and spraying equipment. We're committed to providing customers with professional precision machining, customized services.

7 production process, technical support, quality inspection, mold making die casting production, machine production surface treatment, and supporting facilities. Our company has Gearbox housings machining centers, completely automatic cold chamber island die-casting production lines ranging from 150 - 4000 tons. The company also has various ancillary facilities and numerous large-scale precision measurement equipment and instruments, with an annual production of 50,000 tons of aluminum alloy die casting parts and parts research and development production and precision processing capabilities to get the impact of large-scale production.

Our company was established in 2006. was founded. We are specialized in die-casting aluminum alloys as well as precision machining and Gearbox housings components. We support 24-hour human online support and communications with minorities in a variety of languages. Additionally, we have the service team to help with the project.

The products are produced by the company's own facilities. We have all the details about prices, ranging from raw materials to production and even services. The company is Gearbox housings with more than 20 die-casting industry experts and over 80 mold professional engineers. We can provide molds and production solutions for our customers. Our product design is customizable. It is able to provide the conditions needed to produce small batches.