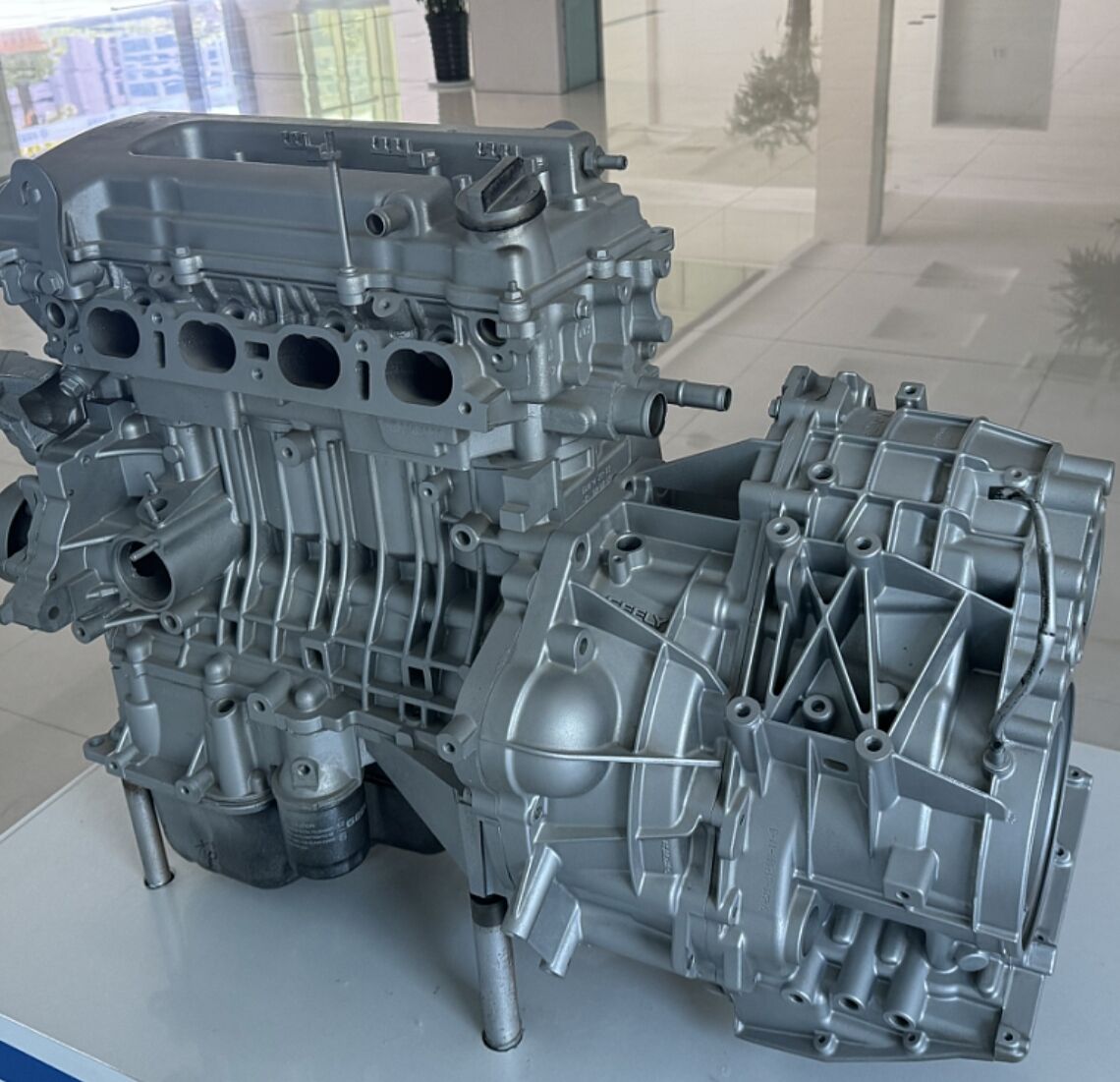

This is a question: You ever see something fully golden and metal? It could be made of a thing metal called aluminum after all. Aluminium is strong and durable, let alone not being a heavy metal weigh very little) Aluminium is a common metal, and people use it to make all kinds of things because it's easy to work with. From car parts to kitchen tools, and even on the huge airplanes flying high in the sky.

Wel how do we take aluminium and make these very useful objects with it?. One of the ways to accomplish this is through a procedure called die casting. This is a process of pouring hot liquid aluminum from the mixer to specific shape called mold. The mold is like a specific design container. The hot aluminium is poured in the mold, which cools down and solidify. After cooling down completely, the mould is opened and away from which a solid aluminium piece would be carefully dismantled.

But not all of you can produce such high-quality die cast aluminum parts. And not everyone upholds that standard well. This article will help to provide you with some specific aspects of what a good aluminium die casting manufacturer looks like and why you might want to select one for your particular use.

High-Quality Aluminium Parts

If you require an aluminium part to be custom made by Jincheng, it is always best for them. This way, it must be robust enough to withstand all kinds of weathers and resist breaking easily as long as you use it with care. This is a key checklist to go over as any good aluminium die casting manufacturer should be identified on the basis of these qualities.

Your part will be custom made using the highest quality parts and materials available. Replacing materials is not just about replacing with anything. Things have to be done right; only then will it work out as expected. They will have professional people using the equipment, as well as those that can verify every component made with precision and optimum level of detail. This is significant because well-trained workers will ensure precision manufacturing of the parts.

Innovation and Precision in Producing Aluminum Components Ideas

A good aluminum die casting company is always looking for new and improved methods to produce higher quality products. This will lead them to invest in new technology or tools for part creation with higher accuracy and precision. It also means the things they make will not loose cast aluminum parts as easy and more importantly, will work better.

But through new ideas are not restricted just using the most recent tools and machines. It also means being inventive and finding intelligent ways of solving any manufacturing issues. A trustworthy manufacturer will have a team of experts who know how to realize ideas and are constantly on the lookout for better ways, new methods or products. This is the kind of innovation helps them to get an edge from their competition.

Tailor-made Solutions for Your Aluminum Parts

Customer requirements are varied and therefor unique for customised parts. This is why an excellent casting company will help in delivering these requirements with custom made and individually designed products. Because they know that each project is unique, and so are you.

This company will be rather generous for your listening to exactly what you need and helping to design the perfect part meeting all of your expectations. Moreover, they will provide their suggestions and recommendations according to the knowledge earned by them from this aluminum manufacturing field since years. With this experience, they can give you useful feedback to improve your product.

The Superior in Aluminium Parts Production

Opting for a proper attention in case of an aluminium die casting is very essential as you get assured that the best among many are serving you. These will be individuals that have years of expertise, a background in creating custom casting aluminum parts for different applications. It's OK because you can feel pretty sure they are good at what they're doing.

This could range from designing and prototyping to coloring of parts, or putting them together. It also means there is no need to go elsewhere for you custom part requirements, speeding up the process. When everything in handled by the same manufacturer, it then saves you time and key effort.

High Quality and Economical Prices

While all these positive characteristics are nice to have, they will not do much good if the manufacturer prices themselves out of consideration. A quality manufacturer will work on affordable pricing with no compromise in quality and service. They wish that you have the best oil for your shotgun to get more bangs for bucks.

They will provide the pricing details in advance of service and will work with you to match solutions with your budget. That way you know what your costs are going to be. They will also respond quickly to what you want, offering a great deal of service during the job. The eyes have it - The importance of great communication to an effective partnership

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

KA

KA

BN

BN

LA

LA

MY

MY