Melting Aluminum for Casting: The first stage of the process is to melt aluminum in a furnace. The Jincheng mould for aluminium casting temperature is high enough in this furnace to melt aluminum. The aluminum is then poured into the mold. A mold is a hollow shape which the aluminium can be held in by temporary materials like sand that hold the aluminum and keeps it from moving while allowing to cool. As we all know that when the molten aluminum pours into mold, it cools and hardens inside. Only when it is entirely cooled and hard, the aluminum part is ejected from the mold. The aluminum product is then cleaned and surface finished. It is often further shaped and polished to be smooth.

There are many reasons why aluminum casting is such a lift shop favourite, with advantages in every department. One of the best things about aluminum is that it's strong but lightweight. It has strength as well not easily break, and being light will ease your life handling it or using. Plus, aluminum pieces can last a long time before you need to worry about them breaking. They can also take high heat, so they are used for crucial roles as car engine blocks and parts in airplanes or even pots and pans that one cooks with

Another method to get the best of precision is by utilizing tools and machines that have been designed for this purpose. Advanced machinery, for instance CNC machines -- are used to program the computer to a high degree of cutting and shaping. This technique allows manufacturers to produce highly accurate parts. Besides, the quality of metal also inspected. This aluminum die casting guarantees that the aluminum parts are robust and compliant with required safety standards.

Casting Methods There are multiple different casting methods for aluminum parts, with each method having its own advantages and disadvantages. A brand-forge exists, and the most frequent ways are furnace casting. Mold in Jincheng die casting process made by mixing compacted clay and well-mixed tiny particles of local sands to form the shape with a particular pattern or core. It is a simple and cost-effective method that can be used for mass production of parts.

A method(s) used, often is investment casting. This aluminium die castings begins with the creation of a wax model from which you will be making the said part. This wax model is then covered with a ceramic material. But when then ceramic is fired with wax, the latter burns off and melts away leaving a hollow ceramics shell. Then they pour poured molten aluminum into the shell to make a final part, turning out very accurate and high-quality piece.

In addition, aluminum casting parts not just have low energy requirements however are also positively pulling away which means that they might be recycled and changed a portion of the techniques. Jincheng Aluminum die casting is one of the most recyclable materials and can be melted down to use again numerous times without losing its valuable properties. The recycling of aluminum in this manner reduces the amount of waste created by processing new aluminum products, which is good news for our Earth.

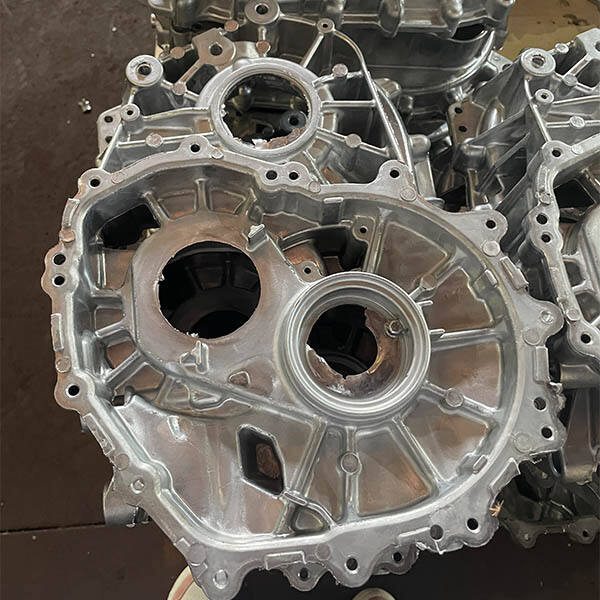

7 production process, technical support quality control, mold production, die casting production, machine production, surface treatment process, supporting facilities. Our company is equipped with 60 modern precision machining centers and fully automated cold chamber island die-casting production lines ranging between 150 and 4000 tonnes. The company also has dozens of large precision instruments and measuring equipment, as well as various related services. The Casting aluminum parts production of the company is 50,000 tons, and it can perform precision manufacturing and processing.

Casting aluminum parts of our production sites: Weitang auto part casting plant, Suzhou Jincheng Precision Casting Plant, Xuzhou Jincheng Precision Casting Plant. The total assets are more than 1 billion Yuan and covers 300 acres. The plant is spread over 180,000 square meters. The company boasts over 600 CNC machines and 60 horizontal machining centers as well as complete electroplating and spraying testing equipment. We're committed to supplying customers with professional precision machining and customized services.

Our company was established in 2006. was founded. We are specialized in die-casting aluminum alloys as well as precision machining and Casting aluminum parts components. We support 24-hour human online support and communications with minorities in a variety of languages. Additionally, we have the service team to help with the project.

The products are produced by the company's own facilities. We have all the details about prices, ranging from raw materials to production and even services. The company is Casting aluminum parts with more than 20 die-casting industry experts and over 80 mold professional engineers. We can provide molds and production solutions for our customers. Our product design is customizable. It is able to provide the conditions needed to produce small batches.