Did you ever where it began? A mold is filled with molten metal that solidifies to create a specific form known as die casting. Communication Filter is an excellent all-around alternative when it pertains to die casting its mainstream solid frameworks. In this blog, we will go deep into the world of aluminium die castings to unearth various benefits they provide, different industries where it is used and new age advancements in technology for Jincheng Die casting.

Aluminium die casting saves costs and improves efficiency during several stages of the production process. Manufacturers achieve cost savings through the efficient material, transportation assembly and maintenance of aluminium parts by adding this weight-saving technology. Also, Photovoltaic Energy Storage Components Products offer unswerving manufacturing processes that result in precise and dimensionally stable end products. Furthermore, aluminium alloys are extremely recyclable making them very sustainable and regulations compliant.

Overhaul Your Product And Make it Better and Stronger With Aluminium Die Casting

Aluminum alloys from Jincheng that have potential to be beneficial and offer many performance and durability improvements are available. As an illustration, aluminium is known for its high strength-to-weight ratio that helps increase the product's structural integrity without adding to weight of a principal design feature as in aerospace and automotive industry. In addition, the corrosion resistance of Aluminum helps prevent rust and surface destruction in demanding environments where exposure to marine or chemical elements exist. These can also be custom-designed to maximize heat conductivity, electrical conductance and abrasion resistance as per the product.

Aluminium die castings are increasingly being used by the automotive industry in several vehicle parts due to a wide range of advantages that they offer. Suspension System Plate help to reduce the weight of cars, trucks and buses, leading to lower fuel consumption levels and emissions. In addition, aluminium is helpful in dissipating heat faster within engine blocks, cylinder heads and transmission housings that further improves the performance of a vehicle as well as extends its lifespan. Outside of these Jincheng components, the automotive industry utilises aluminium die castings in wheels and suspension parts as well as steering components or brake systems from mechanical design there through to even more complex electrical housings.

Aluminium Die Castings can also be molded into complex shapes and surfaces which might otherwise be difficult to form using other production methods. The flexibility of Three-Power System enables the manufacturing of lightweight, thin-walled parts with both functional and aesthetic insides; In addition, die casting produces parts with wide range of good finishing as-cast.

The die casting industry always on the move in response to requirements for better performance, cost savings and environment-consciousness. Eco-friendly alloys: Other new Aluminum alloys are made from recycled materials or with low-energy demands during production, yielding environmental and economic benefit.

Hybrid manufacturing: It is where die casting method combined with other techniques such as 3D printing, machining or surface treatment to obtain more tailored and accurate components.

During the design and manufacturing of die castings, lead time is reduced significantly and product quality is improved through advanced computer simulations using simulation software.

Industry 4.0 will bring smart factories and digitalization of production processes for higher efficiency, less waste, more traceability, and better quality control in die casting operations.

Ultimately, aluminium die castings come with a plethora of benefits for manufacturers and designers looking to create lighter, stronger parts that last longer in many different applications. Operating in the automotive, electronics or consumer goods industry-aluminium die castings provide flexible and competitively priced environmentally-conscious answers to meet your demands. Keep current with the cutting edge in die casting technology to create more design opportunities and improve the performance of your products.

The products are made in the factories of the respective companies. We provide all the information on prices, from raw materials to production and even services. More than 80 mold engineers and aluminium die castings die-casting experts are in the company. Our product design is flexible and we are able to design molds for customers and provide production solutions. It can be used for small-batch production.

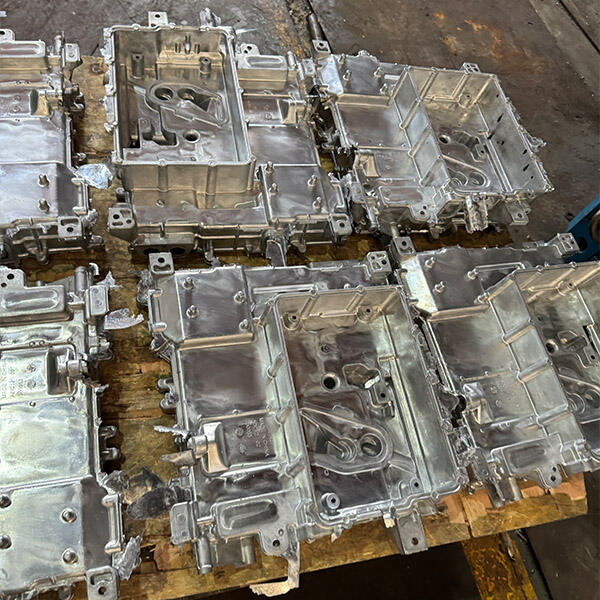

The aluminium die castings production processes are supported by technical support and quality control, mold-making and die-casting, machine production and treatment of surfaces. Our company owns 150 - 4000 tons of fully automatic cold chamber die-casting islands production line 60, and advanced precision machine centers that are more than 600. The company also has a variety of high-precision instruments and measuring equipment, and a variety of other ancillary services. Its annual production is 50,000 tons and it is able to perform precise manufacturing and processing.

We own three important production facilities, Weitang aluminium die castings casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant. The total asset size has exceeded 1 billion yuan and covers the area of almost 300 acres, plant area that is 180,000 square meters. The company is equipped with over 600 CNC machines and more than 60 horizontal machines, as well as a full electroplating and spraying equipment. We're dedicated to providing our customers with the highest quality precision machining customized services.

Our company was established in 2006. was founded. We are specialized in die-casting aluminum alloys as well as precision machining and aluminium die castings components. We support 24-hour human online support and communications with minorities in a variety of languages. Additionally, we have the service team to help with the project.