Cylinder block prevents problems that could interfere with the functioning of a vehicle or machinery. The cylinder head is an important component that helps in preventing a problem with cylinders and holds the system perfectly. Proper care of Jincheng engine cylinder block greatly increases the life and performance of your engine.

For the best performance of your vehicle, opting for an increase in cylinder block can add to a new life altogether. Tiny tweaks to cylinder block in engine of the engine can result in big gains in output and mileage.

There are so many options for every need in the world of cylinder blocks. From the strengthened cast-iron blocks preferred for high-performance applications, to lightweight aluminum which reduces heat. It could take material strengths from cast-iron and lightweight aluminum, for hybrid blocks that combine the best of both worlds in terms of engineering. This new approach to merging materials leverages the properties of both material families against each other, for optimal mechanical interfaces.

Which Cylinder Block Should You Choose For Your Engine

A large number of companies offer quality and reliable products for your engine's cylinder block. Understanding the nature of the block, its weight and what it is made from with quality of process fluids used will help you to get a better decision on which Jincheng cylinder block of engine is for you.

Routine Servicing of the Cylinder Block is Critical

Maintain your cylinder block regularly for your engine running as smooth as possible. Regular checks and fixing small problems may help prevent larger issues. Further optional upgrade paths are available for many parts of the engine to enhance performance in various areas, and make maintenance a little bit more manageable.

Your engine compression ratios need to be just right for achieving maximum power output. The engine performance is dependent on the compression ratio, which is influenced by factors like piston style, engine cylinder block size and stroke length. That perfect balance keeps an engine efficient without pushing it to the ticking time bomb stage.

The cylinder block is the core of all internal components and serves as a mediator for carrying out the engine's operation. Choosing a solid Jincheng cylinder block in engine and maintaining it will help you make the most of your engine for longer. Jincheng dedicated to making the most long-lasting engine components give you plenty of choices. From component materials to load capacity and compression ratio grades that ensure your engine is operating at optimal performance levels.

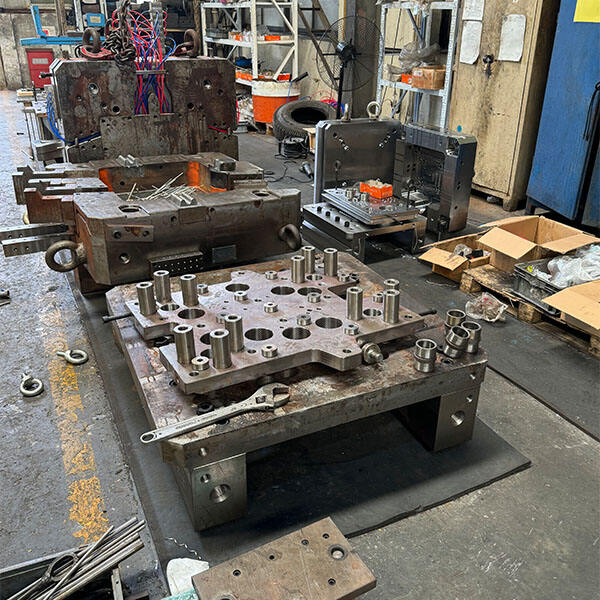

The product is manufactured in the company's own facilities. From purchasing raw materials to subsequent production and processing services We provide detailed pricing details. More than 80 expert mold engineers as well as 20 experts in die-casting are on hand at the firm. Our design for products is flexible and we are able to design molds to meet the needs of our customers, and also provide Cylinder block. It can provide conditions to produce small batches.

We have our own 3 important production facilities, Weitang auto parts casting plant, Suzhou Jincheng Cylinder block, Xuzhou Jincheng precision casting plant; the total value of the assets is more than 1 billion yuan, covers an area of nearly 300 acres, and has a plant space that is 180,000 square meters. The company has over 600 CNC machines with more than 60 vertical CNC machining centers, and a complete spraying, electroplating testing equipment. We offer professional precision machining services that are tailored for our clients.

In 2006, our business was founded. We specialize in die-casting aluminum alloy components as well as precision machining and general industrial components. We support 24-hour Cylinder block service online and also communication with minorities in a variety of languages. Additionally, we have the service team to help with a project.

7 production process, technical support, quality inspection, mold making die-casting production, production of machines Cylinder block, and supporting facilities. Our company boasts 150 - 4000 tonnes of fully automated cold chamber die-casting island production line 60, and advanced precision machining centers more than 600. The company also owns a plethora of high-precision measuring instruments and equipment and a variety of ancillary services. The annual production of the company is 50,000 tons and it is able to perform precise processing and production.