Explain the cylinder block of an automobile engine

The lower part of the engine is called a cylinder block. It is a big piece of metal that has cylinders for engines and supports pistons, crankshafts, etc. A typical large V cylinder block may be made of strong metal such as cast iron or aluminum

There are many important functions that the cylinder block performs. Jincheng die casting is where it burns fuel to produce power. It also acts as a channel for coolant to remove heat from the engine. Additionally, it provides a base for the up-and-down motion of pistons driven by crankshafts.

It would be best to purchase a new one from any reputable company in this case. There are several top-level manufacturers who make excellent quality products like Darton, World Products or RHS which produces high performance Racing Head Service blocks commonly known for being reliable and tough

Darton has developed its own method for preventing damage to cylinder walls that can occur when running high horsepower engines; Jincheng engine block also manufacture various cylinder blocks designed specifically for Ford and Chevrolet engines under World Products brand name while offering very competitive prices on them too; Another good option would be using Thud Block which belongs among highest levels available due to its exceptional reliability combined with affordable price tag (RHS is another great choice).

Like other parts of an internal combustion engine system over time wear out can cause problems if not fixed properly such as cracked/warped wall(s), liner failure(s) etc., all these issues will reduce power output or cause oil leak(s) eventually leading towards complete breakdowns therefore must be resolved accordingly

Cylinder blocks are one of those things that you cannot really fix at home without professional help because they are very difficult; once cracked, Jincheng engine cylinder block usually need replacing hence have no other choice but replacing entire cylinder block; warped walls can usually be corrected using smooth tool on them while if liners are causing or contributing to seam failure(s) then smoothing out/replacing them may fix problem.

To keep your engine running strong and healthy for years to come, follow these tips:

Check coolant level regularly and change it on time

Inspect around the cylinder block of engine frequently for leaks, fix any leakage promptly

Change oil/filter religiously this will help keep everything inside clean and in good working condition

Take a closer look at cylinder block every now and then especially so on powerful engines where wear could easily result into severe damage

They say that better engines have better blocks. These days all they really do is try to figure out how make their engine work more efficiently. For example, car cylinder came up with lighter weight cylinder block idea in Ecoboost motor which saves fuel by making things smoother

There are also some companies that want to use titanium or carbon fiber materials in making their cylinder blocks lighter thus reducing fuel consumption as well (but only certain degrees).

In 2006, our business was established in the year 2006. We are cylinder block in engine in die-casting aluminum alloy pieces as well as precision machining and general industrial components. We provide online human service all day, every day. We also communicate in a variety of languages. We can also offer a team of service representatives to work with your project.

We own three important production facilities, Weitang cylinder block in engine casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant. The total asset size has exceeded 1 billion yuan and covers the area of almost 300 acres, plant area that is 180,000 square meters. The company is equipped with over 600 CNC machines and more than 60 horizontal machines, as well as a full electroplating and spraying equipment. We're dedicated to providing our customers with the highest quality precision machining customized services.

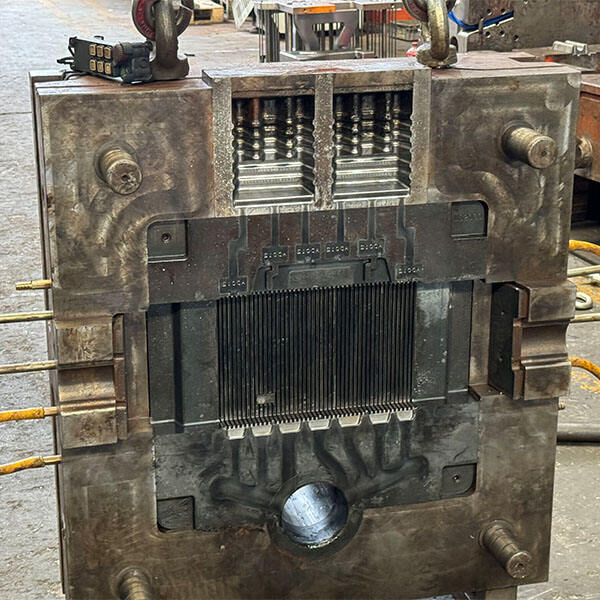

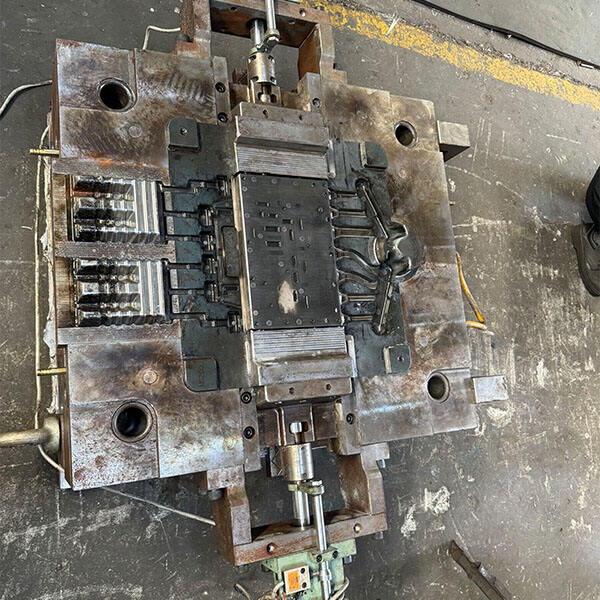

The product is manufactured by their own factories. From the purchase of raw materials to further processing and production services we provide cylinder block in engine details. The company is equipped with more than 20 experts in the field of die-casting and more than 80 mold professional engineers. Our product design is flexible, we can design molds for our customers and offer solutions for production. It will provide the right conditions to produce small batches.

The seven processes of production are tech support, quality control, cylinder block in engine casting, die-casting and surface treatment. Our company has 150 - 4000 tons of fully-automated cold chamber die-casting islands production line 60, high-precision machines that exceed 600. It also has dozens of large precision measuring equipment and instruments, along with a range of other ancillary services. The annual production of the company is 50,000 tons and it's able to do precision manufacturing and processing.