It all happens with the help of cylinder blocks and engine blocks. In the cylinder block, there are these cool cylinders with pistons that moves them making energy from fuel needed to allow an engine run well, the same as Jincheng's engine block. But occasionally the engine's mounting vibrations can cause these cylinder blocks to crack. These cracks can result in catastrophic failures such as complete engine failure. So, how can you tell if your engine is exhibiting a cracked cylinder block?

Engine Overheating: A well-known sign of a cracked cylinder block is when your engine overheats out of nowhere, just like the car cylinder supplied by Jincheng. That could come by way of a higher temperature reading on the gauge in your dashboard or with any number of warning lights.

Cast Iron vs. Aluminum Cylinder Blocks

Their strength is one of the reasons that cast iron blocks are still used, but again steel can be stronger. Lightweight and exceptional at high temperatures, also the Jincheng's product such as gearbox house. It is also important to ensure the cylinder block has proper engine fluid levels, and you need to check on it weekly so that it remains strong and does not damage.

Running regular checks on the cylinder block to search for minor cracks or even leaks, should help you in avoiding any successive engine problems, the same as car cylinder supplied by Jincheng. If the block becomes clogged or begins to leak, it can cause engine failure which will result in expensive repairs.

This could be an indication of a cracked block if your engine begins to overheat, loses power, or develops strange noises, just like the Jincheng's product called cylinder block of engine. Additionally, you might see white smoke or bubbles in the coolant tank that indicate a defect. A block tester is good to have for sniffing the cylinder block cracks.

The cylinder block needs to be considered more often, but by doing so you can help protect the engine and save yourself from an expensive repair in future.

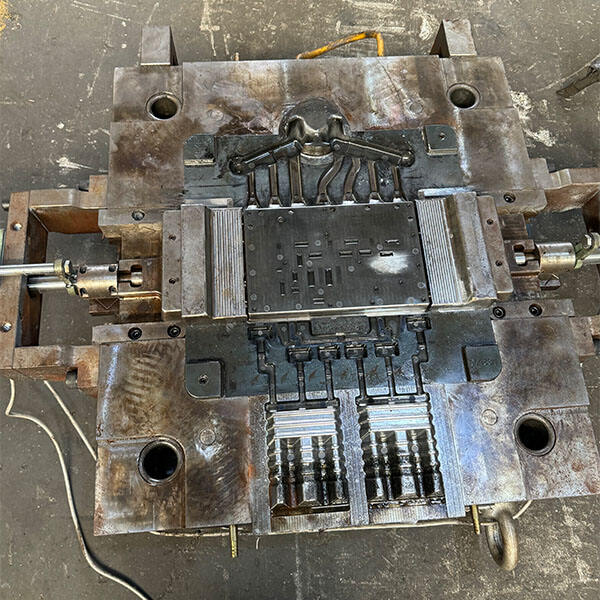

In 2006, our business was established in the year Cyl block. We specialize in die-casting aluminum alloy components as well as precision machining and general industrial components. We offer 24 hours of human-to-human online service as well as communication with minorities in a variety of languages. We also have a service team to connect with a project.

7 production process, technical support, quality control, mold production, die-casting production, machine production, processing of surfaces, as well as other facilities. Our company is equipped with 150 to 4000 tons of fully automated cold chamber die-casting island production lines 60, and advanced precision machines that exceed 600. Additionally, the company includes ancillary facilities as well as numerous large-scale precision measurement Cyl block and equipment, with an annual production of 50,000 tons of aluminum alloy die-casting components and research and development of parts, production and precision processing capabilities to get the impact of large-scale production.

We own three important production facilities, Weitang Cyl block casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant. The total asset size has exceeded 1 billion yuan and covers the area of almost 300 acres, plant area that is 180,000 square meters. The company is equipped with over 600 CNC machines and more than 60 horizontal machines, as well as a full electroplating and spraying equipment. We're dedicated to providing our customers with the highest quality precision machining customized services.

All of our products are produced at the facilities of their Cyl block companies. We have all the details on pricing, from raw materials to production and even services. More than 80 mold engineers as well as 20 die-casting experts are on hand at the firm. Our product design is nimble, we can design molds to meet the needs of our customers, and also provide solutions for production. It is suitable in small-batch production.