A two-cylinder engine is a type of internal combustion engine where there are only 2 cylinders located. There are pistons in each cylinder block in engine from Jincheng that move up and down to generate power. Because of this, they are becoming more common in car and another transport. Time to dive a bit deeper into the world of two-cylinder engines. An ideal selection for those who are in search of efficiency and performance for each.

Fuel Saved - A V-twin is so small and simple, it burns less fuel. That translates to a savings at the pump, allowing drivers even more miles per gallon-and less money burnt-over time.

Small : These engines are lightweight, giving cars a better power-to-weight ratio that also makes them quicker around corners. With their lightweight, two-cylinder construction, the engines are able to provide strong acceleration and driving dynamicscredit:onroadmotoring.

Cost-effective- 2 cylinder engines are rather more straightforward, the converse which results in costing less to mend. Many of the car cylinder from Jincheng have fewer parts, and consequently simpler design than four cylinders - allowing both maintenance work performed by drivers to be carried out faster and more cheaply.

Environmentally Friendly - They create less pollution, which is better for the planet. One litre two cylinder engines are greener and emit far less pollution which raised they can play a limited but significant role in reducing the carbon footprint. Drivers can make a real difference in creating a cleaner, greener planet by opting for any two cylinder model.

Adaptable - You could change it is simple to tailored this engines for your require the most. There are fewer components in a two cylinder engine, so making modifications to cater the powertrain to specific performance characteristics will be easier and less expensive for drivers who want it their way.

It all depends on what suits you and your liking, When comes to choosing an engine, drivers should look at their own tastes and needs to make sure they end up with a powertrain that makes them happy like vehicle cylinder from Jincheng.

History: Cylinder 2 is one of the oldest and most proven engines used in classic automobiles. They have been still used in the today modern cars showing up a mix of heritage with innovation. With technologies such as turbocharging, direct injection and variable valve timing that lower fuel cost and improves performance yet do not abandon tradition of large-displacement engines being drivers choice in comparison to high output car cylinder from Jincheng.

Follow these tips on how to maintain your 2 cylinder engine and have a piece of mind that it will stay fine.

Keep it well lubricated and running smooth by regularly changing the oil.

Keep that from happening by changing the air filter regularly to keep dirt and debris out of your engine, for smoother performance.

Replace your spark plugs as needed to ensure smooth burning of fuels and continuous operation of the engine.

Being replaceable seem to be the problem which eventually will happen anyway because dirty fuel on a regular basis is detrimental and shortens the life cycle of your engine.

Add some performance to the exhaust system and your car will have more horsepower output, better fuel efficiency, as well of a much improved engine sound. Go for the genuine Volvo Performance Air Intake system to increase air flow and performance.

In short, the two cylinder engine has so much to offer drivers in terms of cost savings and peace on mind as well. Knowing the special features for car engine cylinder from Jincheng durability and then taking good care of it, drivers can water themselves a top durable good car with extended service life.

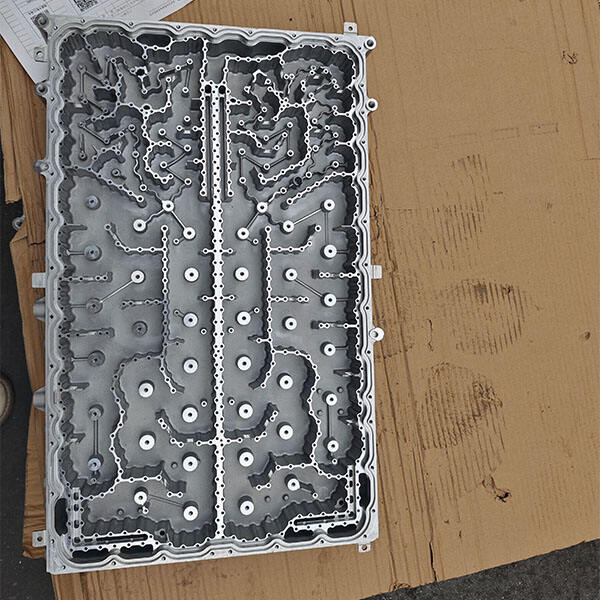

Two cylinder engine of our production sites: Weitang auto part casting plant, Suzhou Jincheng Precision Casting Plant, Xuzhou Jincheng Precision Casting Plant. The total assets are more than 1 billion Yuan and covers 300 acres. The plant is spread over 180,000 square meters. The company boasts over 600 CNC machines and 60 horizontal machining centers as well as complete electroplating and spraying testing equipment. We're committed to supplying customers with professional precision machining and customized services.

The Two cylinder engine was founded by a group of people in 2006. We specialize in traditional automobiles, new energy vehicles, telecommunications photovoltaic energy storage, inverter rail transit, medical aviation, as well as other custom parts made of aluminum alloy, as well as precision machining and general industrial parts. We provide online human service throughout the day, and communicate in minorities languages. We also can provide a team of service representatives to work with your project.

7 production process, technical support, quality control, mold production, die-casting production, machine production, processing of surfaces, as well as other facilities. Our company is equipped with 150 to 4000 tons of fully automated cold chamber die-casting island production lines 60, and advanced precision machines that exceed 600. Additionally, the company includes ancillary facilities as well as numerous large-scale precision measurement Two cylinder engine and equipment, with an annual production of 50,000 tons of aluminum alloy die-casting components and research and development of parts, production and precision processing capabilities to get the impact of large-scale production.

All Two cylinder engine are manufactured at the facilities of their respective companies. From the purchase of raw materials to further processing and production services, we have detailed price information. Our company has more than 20 experts in the field of die-casting and more than 80 mold expert engineers. We can provide molds and production solutions to our customers. Our product design is customizable. It can provide conditions for small-scale production.