CNC machines certainly changed the factory floor today. CNC: Computer Controlled machines for cutting or shaping the hard materials such as metal, plastic. Until quite recently, the act of making things properly was a laborious and slow process. But now CNC machines can do this faster and better in all dimensions. That Engine Plate is why we are seeing an increasing number of companies using these robots in their factories. They enable trade to run smoothly and create high-quality products.

One of the big things that I think a lot about is how CNC machines have an equal potential to produce items again and again with no degradation in quality. This is excellent for business that needs to mass produce an item in simply the appropriate type. This Jincheng involves in the event a company needs thousands off car piece that are needed around every single part then it would mean they can certainly make these pieces at speed with precision because of CNC machine you can learn more on cnc here. CNC Machining is also well suited for the production of refined, complex designs that would be challenging to do by hand.

Reduced Waste: One of the Advantages of CNC Machining This Jincheng is because they are sharper and cut a little cleaner generating much less scrap. This is not only good on the budget for a company but also greener. This Transmission Plate minimized waste allows the company to save its costs, and by extension less pollution as well many other problems related to environmental resources were being solved in this way.

This special software operates CNC machines. The device receives clear instructions on the cutting area and depth. Tools such as drills or routers are added in the machine for cutting into the materials and contouring each material. This means that the machine has tensile element and thus works with human shapes (hands).

A revolution is also underway in the vast majority of CNC machines. Like in Car manufacturing, it was a cumbersome process to make parts of cars manually. After that Jincheng now a day we have CNC machines assistances which help in part production very quick with more accuracy. Cars can now be built to a much higher standard: CNC machines mill perfect parts which New Energy Auto Parts fit perfectly together so cars roll off the end of production lines more efficiently and accurately (and are generally better), as with Porsche.

CNC machines are also subsidising for the generation of indispensable medical devices and all. Special implants are created using advanced computer design that can be custom-fitted to the patient's anatomy by their surgeon. CNC Machines had amended the Communication Parts Products medical technology, with these machines implants would be more accurate. As a result, patients are getting better care and increased success rates.

Moreover; CNC machines are designed for programming and autonomous operation. It also means that Photovoltaic Energy Storage Components Products they can keep running for overnight or over the weekend, being idle employees named as #SilentWorker AgroBots. Rather they optimize themselves that leads to better productivity in production and a company can open more stock, less time is produced.

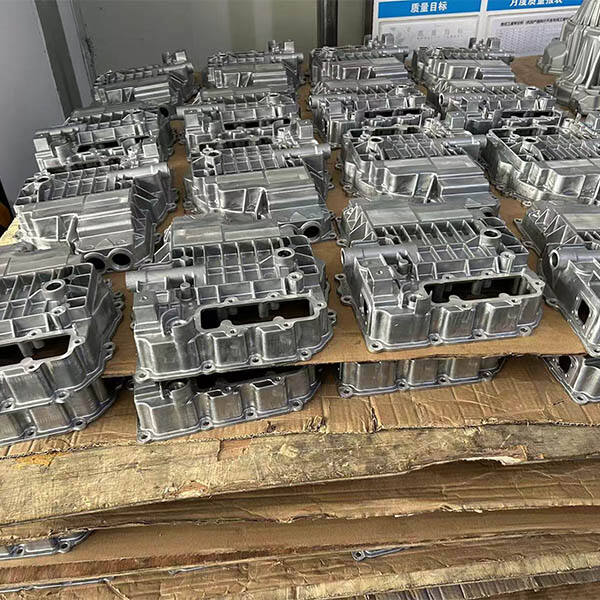

The products are Numerical control machine at the facilities of the companies they belong to. We have all the details about prices, ranging from raw materials, to production and service. The company is equipped with more than 20 experts in the field of die-casting and more than 80 mold professional engineers. Our design of products is flexible and we are able to design molds for customers and provide production solutions. It is suitable to make small batches of production.

In 2006, our business was established in the year 2006. We are Numerical control machine in die-casting aluminum alloy pieces as well as precision machining and general industrial components. We provide online human service all day, every day. We also communicate in a variety of languages. We can also offer a team of service representatives to work with your project.

We have our own 3 important production facilities, Weitang auto parts casting plant, Suzhou Jincheng Numerical control machine, Xuzhou Jincheng precision casting plant; the total value of the assets is more than 1 billion yuan, covers an area of nearly 300 acres, and has a plant space that is 180,000 square meters. The company has over 600 CNC machines with more than 60 vertical CNC machining centers, and a complete spraying, electroplating testing equipment. We offer professional precision machining services that are tailored for our clients.

The seven production processes include the following: technical support, quality control, mold-making die-casting, machine production and surface treatment. Our company Numerical control machine 150 - 4000 tons of fully automatic cold chamber die-casting production lines 60, and advanced precision CNC machining centers with more than 600. The company also owns a plethora of high-precision instruments and measuring equipment, as well as various additional services. Its annual production is 50,000 tons and it's able to do precision processing and production.