A metal CNC machine can be of great help if you are looking to produce fine and precision metal-based products. This machine could be directed by a computer to move it precisely instead of using our hands. It shapes, molds and creates metal in any shape you ask for.

A metal CNC machine is strong and can easily slice right through thicker metal. It is very powerful that can accomplish good result on big tasks with ease. Jincheng cnc metal lathe works very fast and precise, so you are able to lightning metal parts. This is ideal for creating large numbers of identical parts at a time, which happens with mass production. Mass production is critical when you want a lot of the same pieces for projects.

Making metal stuff that doesn't look like a typical design from an old mill with lots of tools. Think outside the box and make fun interesting designs. Jincheng cnc machining is capable of producing shapes and styles that are impossible to create manually. This is where you can make those 3D buttons pop, colors stand out with interesting patterns and special characters that have their own unique theme.

Great for Personalized High-End Custom Items

A metal CNC machine can be used with different tools to achieve various effects. You can make a wide variety of metal parts using carving, drilling or tapping techniques. Every tool can do something unique! There are many materials available like aluminum, steel, copper or brass. That means that you can produce a wide variety of products for many different purposes ranging from small pieces to large machinery.

CNC has revolutionized the way metal parts are made, in more ways than one. The first big way is it speeds up the production. Jincheng cnc machining always use purpose-built tools because when making the jig and fixture again, you can create an awful lot of many parts very rapidly. This makes it easier to deliver on what customers need.

It is necessary to mention that CNC technology ensures our metal parts in a more precise way but hygienic process. Exact cuts are important and that is something the machine can do creating designs of all being identical. The cnc machining also makes all parts align better, which is very important in many projects. It also translates to less waste as you are only cutting what is needed.

Another advantage of CNC machines is that they are less prone to errors than human beings. And they have built in instructions for the parts, so you can be sure each part is made exactly alike every time. The cnc machining helps keep you secure and reduces errors. People can get tired of working unlike CNC machines. Working best on continuous basis, without demanding time for breaks and rest again leads to stable good results.

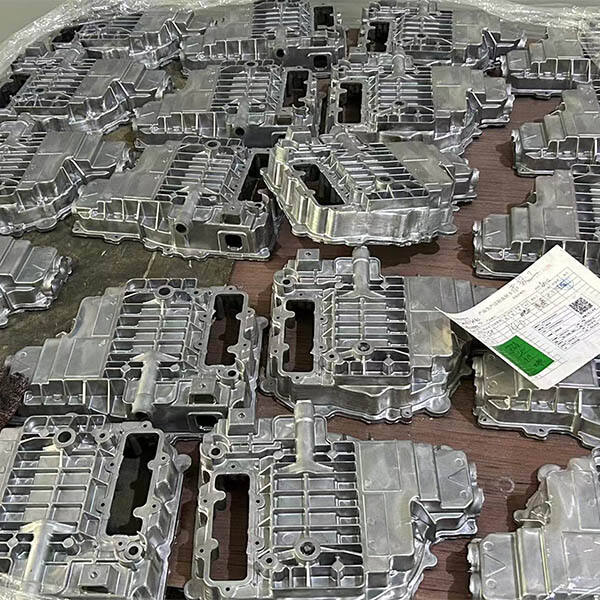

Our company was established in 2006. was founded. We specialize in die-casting aluminum alloys as well as Metal cnc machine machining and general industrial components. We provide human-powered online service throughout the day, and communicate in languages of minorities. We also have the service team to help with a project.

The goods are made in their own factories. We provide all the information regarding prices, from raw materials through production and services. More than Metal cnc machine expert mold engineers and 20 experts in die casting are on hand at the firm. We can supply molds as well as production solutions for our customers. Our product design is flexible. It can provide conditions to produce small batches.

We have our own 3 major Metal cnc machine, Weitang auto parts casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant; the total asset size has exceeded 1 billion yuan and covers an area of more than 300 acres, and has a plant space that is 180,000 square meters. The plant has over 600 CNC machines with more than 60 vertical machining centers as well as complete electroplating, spraying and testing equipment. We offer professional precision machining solutions that are customized to our customers.

The seven processes of production are tech support, quality control, Metal cnc machine casting, die-casting and surface treatment. Our company has 150 - 4000 tons of fully-automated cold chamber die-casting islands production line 60, high-precision machines that exceed 600. It also has dozens of large precision measuring equipment and instruments, along with a range of other ancillary services. The annual production of the company is 50,000 tons and it's able to do precision manufacturing and processing.