Ever wondered how a car engine works? It may sound a little convoluted, well, because it is. Different parts of an engine cooperate to contribute its smooth functioning but the key part among all is called a block. The block is kind of the heart and soul or foundation to them engine if you will. For a structure to remain being something, as is ensured by strong bases for constructions we need it sturdy and correct which also describes the importance of having an un-wrecked engine block.

Allow me to illustrate an example of one block that holds very solid among most car lovers and enthusiasts, it is the aluminum hemi block. Today we have prepared a special article for all of you regarding the Jincheng aluminum block engine and why a certain block is perfect for your engine, along with answering all questions surrounding it that many racers apparently are willing to ask.

One of the primary benefits to aluminum is that it weighs less than cast iron (which most standard engine blocks are composed of and helps contribute to better balance on your car. A light engine will make your car faster, and use less fuel. A lighter car is able to accelerate faster and behave better on the road.

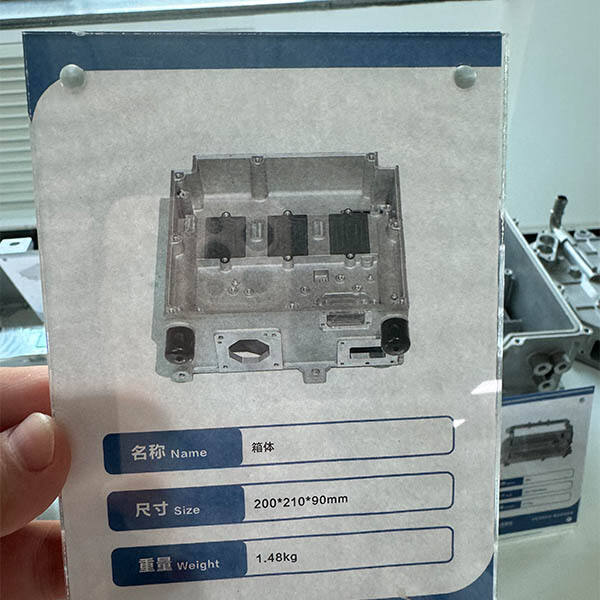

Another great advantage of Jincheng aluminum is its corrosion resistance feature, it does not rust easily as cast iron. That means, if you were to choose an aluminum hemi block (seen above), it will be more durable and take less attention in the long haul. It will not have the potential to do so much rusting of your engine.

Heat Tolerance: Aluminum can withstand heat considerably greater than cast iron. It does so by allowing an aluminum hemi block to keep its cool and not overheat, which will cause the engine fatiguing from high temperature. Maintaining Jincheng aluminium engine block at a dependable temperature is critical and advantageous to the general well-being of your engine.

Strong - While lighter than cast iron, Aluminum is still very strong. It is capable of dealing with the pressures and stress from an engine running without warping or breaking during use. The reliability component is essential, and this strength resides in regulatory action of aluminum cylinder block.

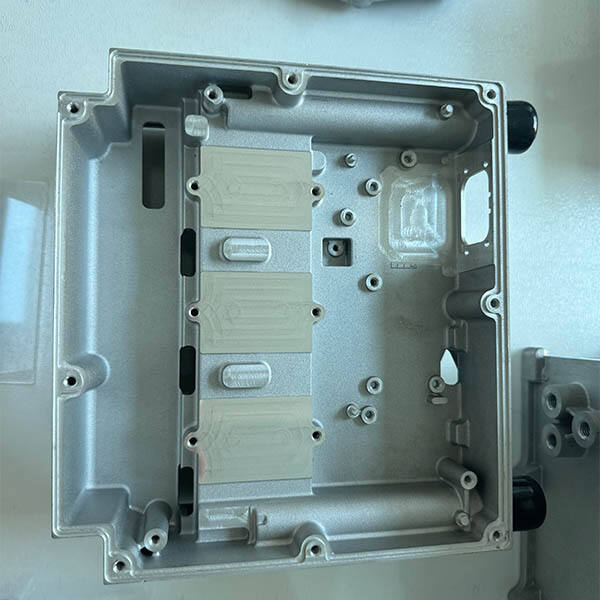

Pistons and Valves: These Other Parts Matter When building or upgrading an engine, don't forget to consider all the other parts. An aluminum hemi block goes a long way towards those goals, but if the thing's end doors off with bearing caps hanging out of them it's very much all nodes and no go.

The products are produced by the company's own facilities. We have all the details about prices, ranging from raw materials to production and even services. The company is Aluminum hemi block with more than 20 die-casting industry experts and over 80 mold professional engineers. We can provide molds and production solutions for our customers. Our product design is customizable. It is able to provide the conditions needed to produce small batches.

7 Aluminum hemi block procedure, technical support, quality inspection, mold making die-casting production, production of machines, processing of surfaces, as well as other facilities. Our company owns 150 - 4000 tons of fully-automated cold chamber die-casting island production line 60, high-precision machine centers that are more than 600. The company also includes ancillary facilities as well as numerous large-scale precision measurement equipment and instruments. They have the capacity of 50,000 tons of aluminum alloy parts for die-casting as well as parts research and development production, as well as precision processing capabilities, to attain the benefits of production on a large scale.

The Aluminum hemi block was founded by a group of people in 2006. We specialize in traditional automobiles, new energy vehicles, telecommunications photovoltaic energy storage, inverter rail transit, medical aviation, as well as other custom parts made of aluminum alloy, as well as precision machining and general industrial parts. We provide online human service throughout the day, and communicate in minorities languages. We also can provide a team of service representatives to work with your project.

We have our own 3 Aluminum hemi block production facilities, Weitang auto parts casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant; the total assets have surpassed 1 billion yuan and covers the area of almost 300 acres and a plant area of 180,000 square meters. The company is equipped with more than 600 CNC machines with more than 60 vertical machining centers and complete electroplating and spraying equipment. We're committed to providing customers with professional precision machining, customized services.