Question: What is CNC Cutting? What is initiated by CNC? This is where computers assist in the control of machines or hand-operated cutting shapes into different materials. Those Jincheng Communication Parts Products materials can be wood, metal, plastic or even food! And above news we will use CNC cutting that is super solid and helpful as it can reduce such designs which if made by hand would begin content language, quite a ton of pain the ass. How can you cut a complex shape or a perfect circle with just scissors? It would be very hard! CNC cutter can easily do it with precision.

Benefits of CNC cutting The combination to its precision is the CNC cutting, which makes it unique. Being very exact — the laser Jincheng Traditional Auto Parts cutter will make this identical cut over and over, hundreds or thousands of times without so much as growing tired or needing a break. This is why CNC cutting used in most factories. Factories produce many types of part in cars, airplanes and furniture! CNC cutting is quick-definitely one of the major advantages. That is one of the important things for a business because they can save time and money with this speed so consequently, work fast.

The CNC cutting technology is developed to assist individuals in work effectively and produce more items in less time. What's great about CNC Jincheng Products machines for sale is that they can operate around the clock without any rest, like a tireless machine. More accurate in cutting less material squandered as they can do super-dead-on cuts. So, that means more products can be made from the same amount of material. CNC cutting technology is prominent in giant factories but knowing that it could definitely come to aid small businesses and people who like making things at home. CNC cutting - How it can help you improve your work, hobby or professional

Said by cnc cutting they provide a stunning result and it turns idea safe in to real output. This implies that on the off chance you can consider it, a CNC machine may ask about an issue for creating. In other words, let's say you are imagining a toy or even any jewelry element; then CNC machines have enough versatility to cut intricate shapes and designs into the metal for your project. They are also able to replicate the same item repeatedly, which is great for creating things such as toys, jewelry and even phone cases! The benefits of using CNC cutting are that it allows the creation to be taken from an idea and turned into a real product which can either make money or given as gifts to friends and family, so why wait, start now by downloading one of our free files community blog.

Another advantage of this practice is it allows clients the opportunity to craft a unique design, specifically catered towards their specified needs and/or preferences. Individuals can thus create unique applications that differ from anything else. People use these machines to cut precise shapes (for personal jewelry, custom signs) and even make stunning pieces of art. CNC cutting technology allows us to put even the most custom design you can dream up into production so we might have something not just functional, but unique and yours.

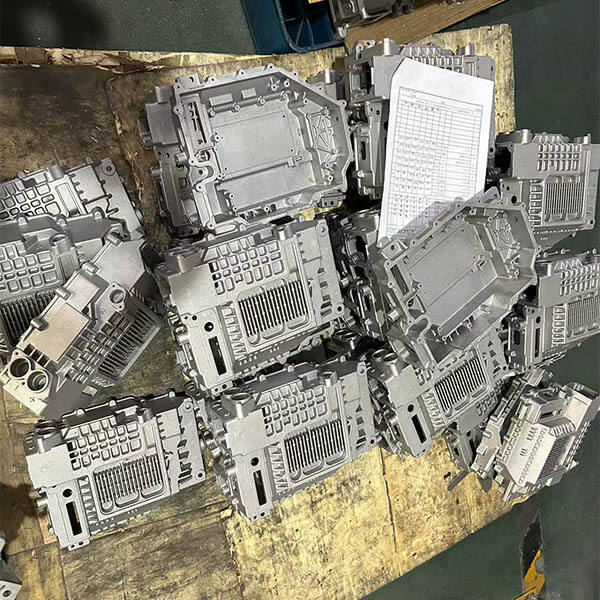

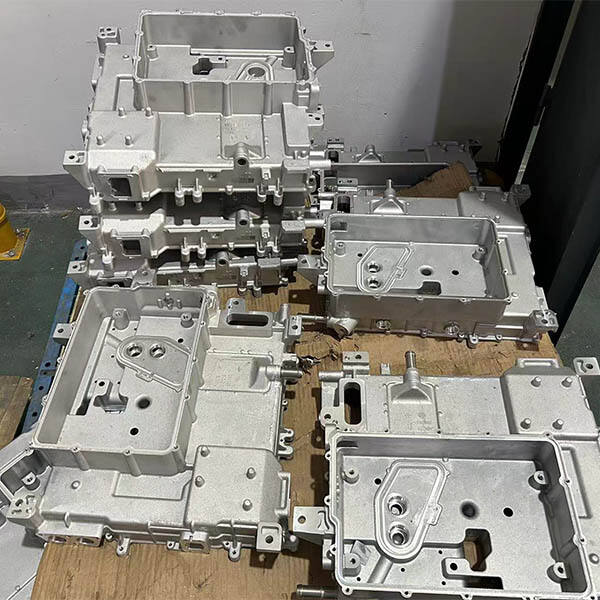

We have three production facilities: Weitang auto part Cnc cutting, Suzhou Jincheng Precision Casting Plant, Xuzhou Jincheng Precision Casting Plant. The total assets of the company exceed 1 billion Yuan and covers an area of 300 acres. Our facility covers 180,000 square metres. The company boasts over 600 CNC machines with 60 horizontal machining centers as well as complete electroplating and spraying testing equipment. We're committed to supplying our customers with high-quality custom machining services.

Our company was established in 2006. was founded. We are specialized in die-casting aluminum alloys as well as precision machining and Cnc cutting components. We support 24-hour human online support and communications with minorities in a variety of languages. Additionally, we have the service team to help with the project.

7 production process, technical support quality control, mold production, die casting production, machine production, surface treatment process, supporting facilities. Our company is equipped with 60 modern precision machining centers and fully automated cold chamber island die-casting production lines ranging between 150 and 4000 tonnes. The company also has dozens of large precision instruments and measuring equipment, as well as various related services. The Cnc cutting production of the company is 50,000 tons, and it can perform precision manufacturing and processing.

All Cnc cutting are manufactured at the facilities of their respective companies. From the purchase of raw materials to further processing and production services, we have detailed price information. Our company has more than 20 experts in the field of die-casting and more than 80 mold expert engineers. We can provide molds and production solutions to our customers. Our product design is customizable. It can provide conditions for small-scale production.