Have you ever ask yourself how do we able to cut with a shape the really very hard material like metal and plastic. The laser technology, as a CNC Jincheng Communication Parts Products machine is one special tool helping us to do the precise cuts and designs in an easy and accurate way. This gives us the ability to produce things that we can benefit from day after day.

What is CNC Machine CNC full form: Computer Numerical Control What this means is we can instruct a machine exactly how to cut that material in the way we want it done. Think of the most obedient robot you can! Laser - a device in which light is emitted that uses multiple tubes fused together to amplify the lewisite rays it generates far beyond its original strength. When we merge the two 3d printings and laser cutting it gives as an opportunity to create huge number of products quickly, so this is a fast solution for creating items which are needed by us.

Perhaps the most apparent benefit of CNC laser Jincheng Traditional Auto Parts cutting is its accuracy. The laser is really precise, and therefore allows us to do tiny details, so that the end result looks exactly how we want it. Being even a thousandth of an inch off may not sound like much to you or me, but in making parts for machines and gadgets with critical tolerances it can mean the difference between success and disaster. A minor error can lead to some worry.

The best part regarding CNC laser technology is that it could possibly work on its own so a employee does not have to be current at the entire time. A printer that can read the design code and cut/engrave (design) Cut and engraving machines vs. printers. This will save a lot of time and you can also prevent mistakes which might happen when humans are working on it. It almost sounds like a smart assistant that can function on its own.

An automated CNC laser-cutting can furthermore be interlocked with another machinery and software. This in turn will mean that everything works together better and a smoother production process. And machines that communicate can save money and have a great product output. This Jincheng Products is a major plus for businesses who want to outplay their competitors.

This is particularly useful when building prototypes, an initial version of a product made to demonstrate its concept. CNC laser cutting makes it possible for companies to create these prototypes in a short time, thereby allowing them improve them subsequently prior to producing large batches. This enables businesses expedite their products from development to customers faster than other competitors and rival firms in the market.

Marking - the script which practitioners heat up and touch it to a product, much like branding cattle- allows for detailed information about an asset such as its serial number or company logo. A powerful, permanent mark can be created with a laser that will last for decades to help consumers more easily identify the product.

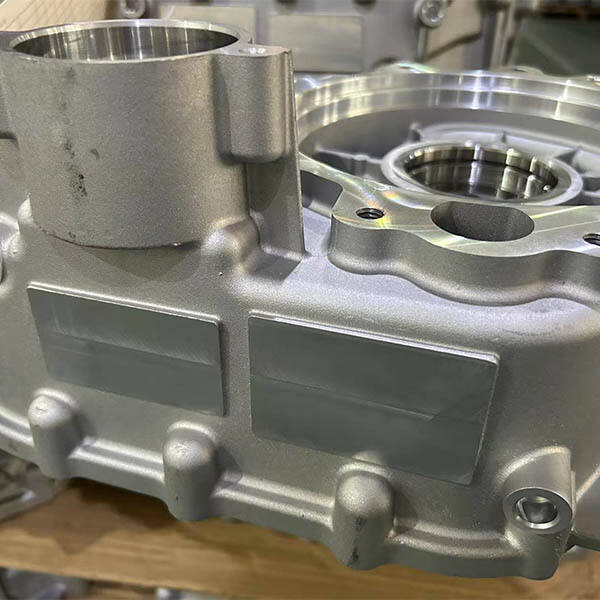

We have our own 3 Cnc laser production facilities, Weitang auto parts casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant; the total assets have surpassed 1 billion yuan and covers the area of almost 300 acres and a plant area of 180,000 square meters. The company is equipped with more than 600 CNC machines with more than 60 vertical machining centers and complete electroplating and spraying equipment. We're committed to providing customers with professional precision machining, customized services.

The Cnc laser production processes are supported by technical support and quality control, mold-making and die-casting, machine production and treatment of surfaces. Our company owns 150 - 4000 tons of fully automatic cold chamber die-casting islands production line 60, and advanced precision machine centers that are more than 600. The company also has a variety of high-precision instruments and measuring equipment, and a variety of other ancillary services. Its annual production is 50,000 tons and it is able to perform precise manufacturing and processing.

In 2006, our business was established in the year Cnc laser. We specialize in die-casting aluminum alloy components as well as precision machining and general industrial components. We offer 24 hours of human-to-human online service as well as communication with minorities in a variety of languages. We also have a service team to connect with a project.

All Cnc laser are manufactured at the facilities of their respective companies. From the purchase of raw materials to further processing and production services, we have detailed price information. Our company has more than 20 experts in the field of die-casting and more than 80 mold expert engineers. We can provide molds and production solutions to our customers. Our product design is customizable. It can provide conditions for small-scale production.