Cylinder- This part is used in the diesel engine. Its where fuel and air come together in a heartbeat to ignite that force which propels the vehicle forward. The Jincheng cylinder is essentially the point of the engine were, all exciting action happens. Diesel engines tend to be multi-cylinder because it is known that more cylinders help these type of engines run in a balanced manner Understanding how the 4 cylinder motor operates will allow your car to run smoothly for many more years.

The cylinder of a diesel engine has an incredibly important role to play as it is the very heart and soul of how any given motor will perform. It packs the air to a very tight and high-pressure format. This means that the air in five cylinder engine has been squeezed into a tiny area, which makes it incredibly hot. Diesel fuel is then injected into the Jincheng cylinder as air enters it under this high pressure. This mixture of fuel combines with compressed air and results in a huge explosion. This explosion is what creates the power that propels your vehicle forward. And it is a little boom that moves your car or truck.

Care of your diesel engine cylinder is so important to the health and life span of your vehicle. Like for instance the cylinder has to be new as if it is not good then nothing works properly and in time. Taking care of a vehicle with maintenance allows you to catch problems sooner rather than later when they are more expensive. It is like going to the doctor for regular appointments so you stay healthy. It is quite important to maintain the cleanliness of that cylinder because any dirt, dust or whatever debris could go inside hurt your precious baby. The last thing you want is for the dirt to collect up, and when that happens it can cause some serious problems in a couple thousand miles down the line. Regular oil changes are very important because clean oil helps to protect the Jincheng 6 cylinder motor and other parts of your engine. If you consider oil to be the lubricant that keeps everything running smoothly.

Diesel created a diesel engine cylinder in the late 1800s. His goal was to build the engine which would surpass steam engines commonly used in those days. It was based on the discovery that he could pump air into a cylinder, where adding less fuel than would be used in an equivalent engine made up for its shortfall by being far more powerful. The diesel engine cylinder in exciting new beginnings. All the fun stuff done to design a better diesel engine cylinder since then actually makes it an important and needed part of today's transportation These developments mean that every day, diesel engines power the trucks, buses and other vehicles we rely on.

One of the most substantial power and efficiency differences is made by the diesel engine cylinder. This means the engine has to put in more effort, using up an excessive amount of fuel if a cylinder is dirty or damaged. This can actually reduce the efficiency of your auto and drive up its running cost. It is almost as if you are pushing your life-size grocery cart uphill with 30 pounds of items inside; significantly more effort. However, a smooth and clean six cylinder engine can make your vehicle more efficient in terms of fuel economy constantly. Your vehicle will hence become smoother to drive and more cost effective in operation.

In 2006, our business was established in the year 2006. We are Diesel engine cylinder in die-casting aluminum alloy pieces as well as precision machining and general industrial components. We provide online human service all day, every day. We also communicate in a variety of languages. We can also offer a team of service representatives to work with your project.

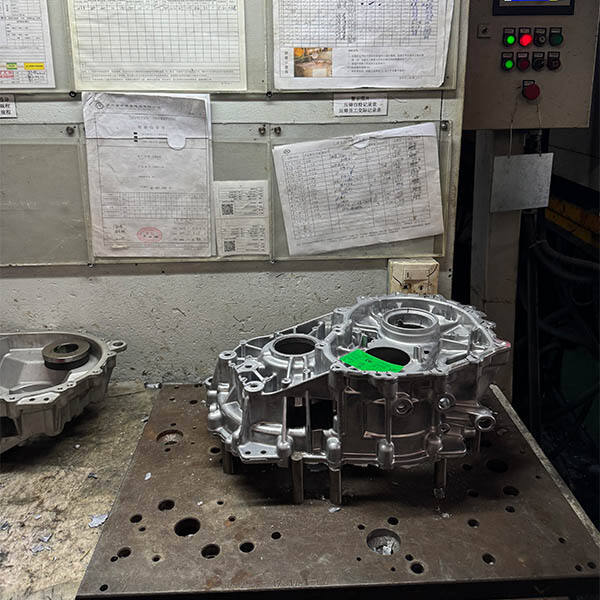

7 production process, technical support, quality inspection, mold making die casting production, machine production surface treatment, and supporting facilities. Our company has Diesel engine cylinder machining centers, completely automatic cold chamber island die-casting production lines ranging from 150 - 4000 tons. The company also has various ancillary facilities and numerous large-scale precision measurement equipment and instruments, with an annual production of 50,000 tons of aluminum alloy die casting parts and parts research and development production and precision processing capabilities to get the impact of large-scale production.

The product is manufactured in the company's own facilities. From purchasing raw materials to subsequent production and processing services We provide detailed pricing details. More than 80 expert mold engineers as well as 20 experts in die-casting are on hand at the firm. Our design for products is flexible and we are able to design molds to meet the needs of our customers, and also provide Diesel engine cylinder. It can provide conditions to produce small batches.

We have our own 3 Diesel engine cylinder production facilities, Weitang auto parts casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant; the total assets have surpassed 1 billion yuan and covers the area of almost 300 acres and a plant area of 180,000 square meters. The company is equipped with more than 600 CNC machines with more than 60 vertical machining centers and complete electroplating and spraying equipment. We're committed to providing customers with professional precision machining, customized services.