Electric motors, however - they are literally monumental at the global scale. These amazing Jincheng long block motor create energy that powers a substantial number of types of machinery, and also home appliances. Electric motors are the helping hands of us not only in reducing our efforts but it also a way to less globe destroying act.

In prehistoric times, homes were dependent on machines that burned gas or oil to produce power. This was bad for the world. Instead, what we have now in our homes with electric motors is the luxury of cleaning greener - and more responsibly -- for tomorrow. This is significant since it leads to our clean environment for future gens and after of us.

Our Home can Save a big deal in electricity Bill with Electric Appliances We are helping to our planet by this way as well without an useless toxicity. Electric Jincheng kicker motor brackets are intelligent in a way as it will convert energy into useful and effective manner. What make a waste of less energy, and that in turn means a brighter future for every sentient being on our planet.

Humans can actually do a thing to destroy the nature? The major problem, here it is the process of burning fossil fuels which release dangerous gases (e. g., carbon-dioxide CO2) into our atmosphere and henceforth can lead to a possible catastrophic nature in terms of environmental degradation.

All The Homes Which Operate By Electric Motor, We Keep Earth Safe. Our local environment plays an essential part in enabling us to live more sustainably, helping produce power through renewable clean sources like solar panels or wind turbines. Then Jincheng big block motor could live our lives and treat the planet with respect.

Yet electric motors are also super at rescuing us when it gets murderous hot or arctic chilly. So, eg if we run our electricity through some sort of system on the house that keeps us warm (like an electric heat pump), then - boom! This not only makes our homes more comfortable, but it saves us money and is also green.

IN THE END: Are you up with morphing your crib into a giant electric-mobil home? Below is just a small list of ways that you could do this. For example, you should put solar panels on your roof and have the majority of appliances inside your home be electric. Bc, we can do baby steps crown of thorns to help our earth.

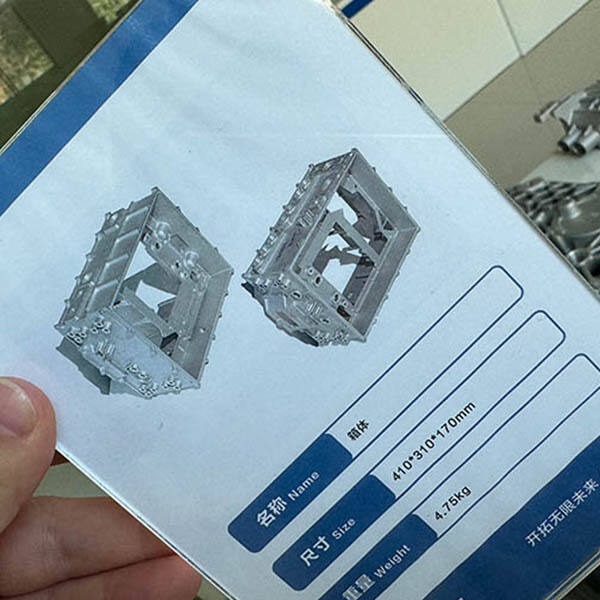

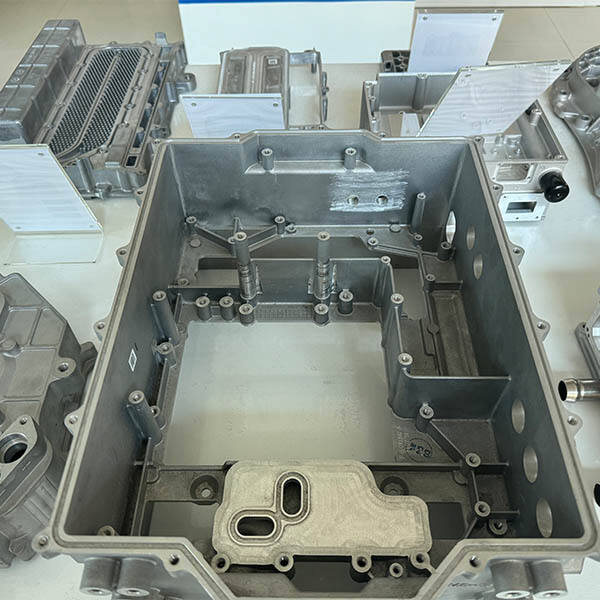

We own three main production centers Weitang auto parts casting plant Suzhou Jincheng precision casting plant Electric motor house precision casting plant The total value of the assets is more than 1 billion yuan covers the area of almost 300 acres with a total area of 180 000 square meters The company has more than 600 CNC machines including 60 horizontal machining centres with complete electroplating spraying and testing equipment We are committed to providing our customers with high-quality precision machining and customized services

Our company was founded in 2006, and is specialized in Electric motor house, modern technology vehicles for energy, telecommunications, photovoltaic energy storage, inverter, medical, rail aviation, and other custom aluminum alloy die-casting components and precision machining as well as general industrial parts. We offer 24 hours of human-to-human online service as well as communication in minor languages. We can also provide representatives from our service department to help you with your project.

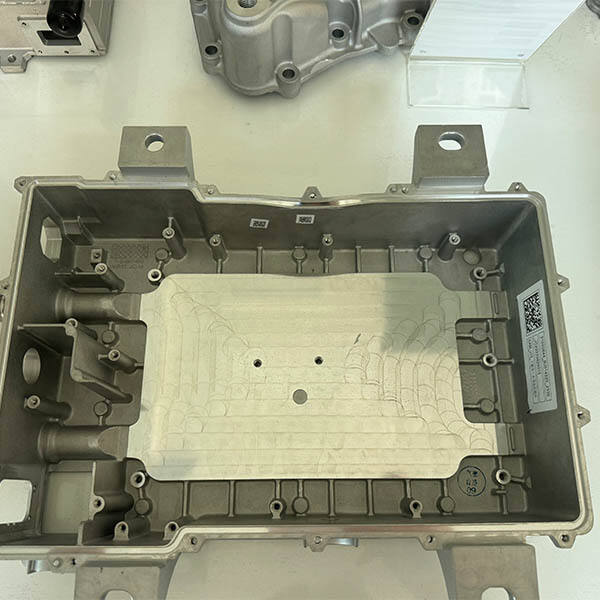

The product is manufactured in the company's own facilities. From purchasing raw materials to subsequent production and processing services We provide detailed pricing details. More than 80 expert mold engineers as well as 20 experts in die-casting are on hand at the firm. Our design for products is flexible and we are able to design molds to meet the needs of our customers, and also provide Electric motor house. It can provide conditions to produce small batches.

7 production process, technical support, quality control, mold production, die-casting production, machine production, processing of surfaces, as well as other facilities. Our company is equipped with 150 to 4000 tons of fully automated cold chamber die-casting island production lines 60, and advanced precision machines that exceed 600. Additionally, the company includes ancillary facilities as well as numerous large-scale precision measurement Electric motor house and equipment, with an annual production of 50,000 tons of aluminum alloy die-casting components and research and development of parts, production and precision processing capabilities to get the impact of large-scale production.