Water is one of the key resources in our planet. After all it helps us to grow food, wash our laundry and brush teeth! While most of you would have heard about using water, wait what can be cut with such WATER? This is where the water jet cnc machines do miracle work. The cnc water jet cutter from Jincheng cut through various materials in a very unique manner with the help of water.

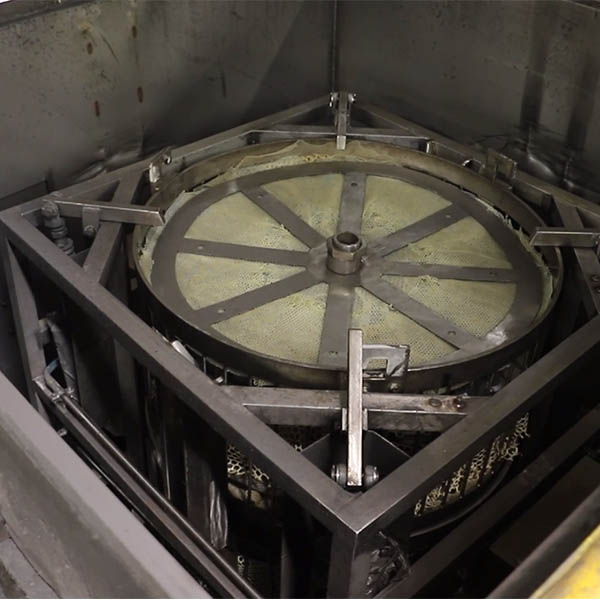

Water jet CNC machines accomplish this by emitting water out of a very small hole. This results in a high-pressure water stream that can even cut into hard objects. For this purpose, it can cut metals or plastic and even woods! This is exactly what makes these machines so important in factories and workshops.

The water jet CNC machines are truly meant to be rough and tough. This is because they are able to last for a very long time without getting spoils. When companies are in need of a sensitive machine to assist them in carrying out their duties with maximum accuracy and within the proper time limits, they have nowhere near as much room for error. In many cases, these cnc metal cutting from Jincheng can alter materials as well. For instance, water jet cutting can help to punch holes, shapes and designs in the metal. It is a great option to lower the cost of car parts that must be changed out all too often and for use in other machining. Thanks to the water jet technology, all cropping becomes very precise and that every piece fits together identically with great precision as if it were a puzzle.

Water jet CNC machines are so efficient as it can cut varieties of materials because they do not get affected by the wear and tear. That means cnc machining service from Jincheng can save companies a lot of time and money. Water jet CNC machines eliminate the need to invest in a deprecated machine for virtually every different material-type, but can simply use a single water jet cutting machine.

Workers even find it easier to do the jobs through these machines. They used to do them by hand which was tiring and pretty tough going. Everything has changed now thanks to cnc cutting technology but back then they had carve men who would cut the stone by hand. That way, they can focus on more essential jobs such as verifying that parts are absolutely correct and ready for use.

One such scenario may be that if a medical device, because of the text its is using and not optimized for it properly will have sharp edges which can harm anyone during use. With cnc machining technology, the cuts are so perfect that there is never any of this happening. This would make the devices safer for all who use them.

Water jet cnc machine of our production sites: Weitang auto part casting plant, Suzhou Jincheng Precision Casting Plant, Xuzhou Jincheng Precision Casting Plant. The total assets are more than 1 billion Yuan and covers 300 acres. The plant is spread over 180,000 square meters. The company boasts over 600 CNC machines and 60 horizontal machining centers as well as complete electroplating and spraying testing equipment. We're committed to supplying customers with professional precision machining and customized services.

In 2006, our business was established in the year 2006. We are Water jet cnc machine in die-casting aluminum alloy pieces as well as precision machining and general industrial components. We provide online human service all day, every day. We also communicate in a variety of languages. We can also offer a team of service representatives to work with your project.

7 production process, technical support, quality inspection, mold making die-casting production, production of machines Water jet cnc machine, and supporting facilities. Our company boasts 150 - 4000 tonnes of fully automated cold chamber die-casting island production line 60, and advanced precision machining centers more than 600. The company also owns a plethora of high-precision measuring instruments and equipment and a variety of ancillary services. The annual production of the company is 50,000 tons and it is able to perform precise processing and production.

Each product is manufactured at the Water jet cnc machine of the respective companies. We have all the details about prices, ranging from raw materials to production and services. More than 80 expert mold engineers as well as 20 die-casting experts are available at the company. Our product design is nimble, we can design molds to meet the needs of our customers, and also provide production solutions. It is suitable in small-batch production.