The special way of manufacturing precise parts from aluminium was discovered by people long time ago. This Jincheng is the aluminium casting die method. We call this method as very critical because it encourages people build perfectly fitting individual parts if there is an actual need. In this aluminum casting die article, we will have a deeper discussion about what is aluminium casting die work and why it so perfect.

Aluminium casting is a manufacturing method which allows intricate shapes to be created from aluminium based metal. To do that, it requires the specialization skill, more so than caution investment. Aluminium Casting Die is a method of aluminium casting where the hot malleable metal is poured in to the mould and take out after it gets solid.! This molding helps to ensure that the parts made are very accurate and repeatable every time they are produced. It would be like using a cookie cutter to bake cookies, and each one of your cookies ends up looking exactly the same!

In casting the most vital element would be considered to become a die. The die is the mold that forms the aluminum in its desired shape. Just like any regular work that when it is made out of good materials and designed well the parts will also turn up to be effective as if they are maintained with qualitative excellence. This Jincheng will allow them to function much more effectively and extend their lifespan. On the other hand, if the die itself is of poor quality then either it will break and need replacement often or just make bad parts. This aluminum die casting mold is why using aluminium casting dies must be done in top quality fashion so that great results are reached. With this, a good die can do wonders!

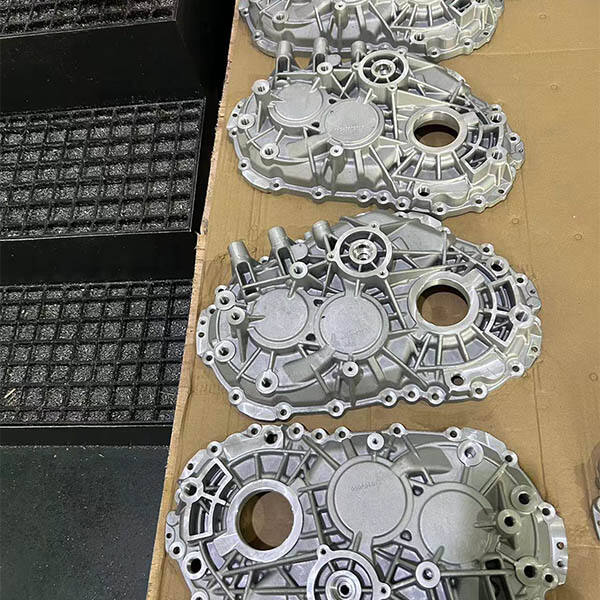

Producing the Die for Aluminium Casting Die The Jincheng die is not easily melted hence it might need to be made from strong materials like steel. Once the aluminum casting ingots die has been made, it is meticulously formed in the shape of a part designed to be created. When the die is prepared and takes its form, proceed to next step in processing.

An aluminium casting die starts with melting the melted aluminum. The aluminium die casting mold pipes are melted using the heat The melted aluminum is then poured into the die. Here the die is filled and then closed down tightly with pressure on it. This pressure forces the Al to conform into a solid after cooling has taken place so it can replicate the shape of what used to be occupants in that space. When it has cooled down entirely, the die opens and a new part is carefully removed. The part is washed and polished as needed to make it pretty and functional.

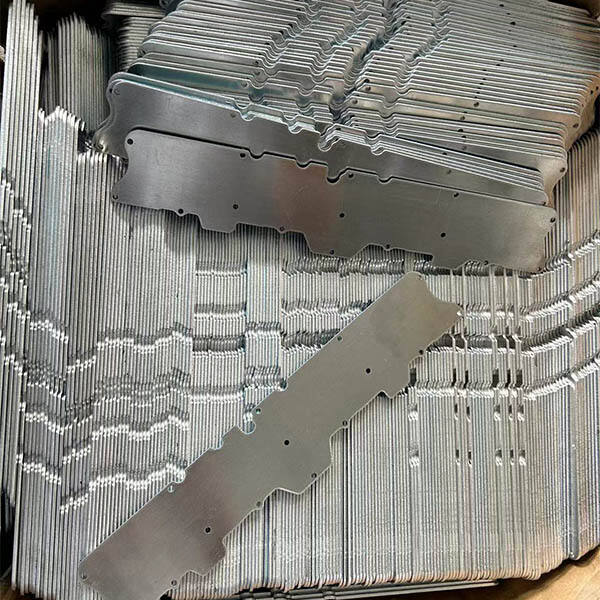

Benefits of Aluminum Casting Dies Above all they fabricate precision parts. It is ideal for machines and other tools because all parts have the same dimensions of size and shape. In addition, aluminum casting die is very rapid, so it can be used for the production of a large number of parts more quickly and cheaply. For businesses producing many parts in a short configuration time, it aluminum die casting components saves money while being efficient and accurate. Moreover, high adaptability of aluminum casting die. It produces parts in nearly every size and shape, so they suit any application you require it to accomplish.

Our company was established in 2006. was founded. We are specialized in die-casting aluminum alloys as well as precision machining and Aluminium casting die components. We support 24-hour human online support and communications with minorities in a variety of languages. Additionally, we have the service team to help with the project.

All of our products are produced at the facilities of their Aluminium casting die companies. We have all the details on pricing, from raw materials to production and even services. More than 80 mold engineers as well as 20 die-casting experts are on hand at the firm. Our product design is nimble, we can design molds to meet the needs of our customers, and also provide solutions for production. It is suitable in small-batch production.

7 production process, technical support, quality control, mold production, die-casting production, machine production, processing of surfaces, as well as other facilities. Our company is equipped with 150 to 4000 tons of fully automated cold chamber die-casting island production lines 60, and advanced precision machines that exceed 600. Additionally, the company includes ancillary facilities as well as numerous large-scale precision measurement Aluminium casting die and equipment, with an annual production of 50,000 tons of aluminum alloy die-casting components and research and development of parts, production and precision processing capabilities to get the impact of large-scale production.

We own three major production bases, Weitang auto parts casting plant, Aluminium casting die Jincheng precision casting plant, Xuzhou Jincheng precision casting plant. The total value of the assets is more than 1 billion dollars, covering an area of nearly 300 acres, plant area of 180,000 square meters. The plant has more than 600 CNC machine tools, more than 60 horizontal machining centers as well as complete electroplating and spraying equipment. We're committed to providing our customers with the highest quality precision machining customized services.