Ever wondered what is the way metal things are made? It is actually quite fun to learn. Jincheng aluminium die castings is a way of making metal objects, first, molten metal is poured into a mold, where it cools and sets (forms) the shape of the casting. The use of the mold for this process is known as die casting mold. A unique mold is sculpted when creating products using aluminum, so that they are the right maximum detail and strength. This is significant since it both changes the visual appearance and callbacks of a product.

After the design, it is time to make the mold itself. It is well-produced, usually with mills and objects helped alongside by skilled trades people in the final stage of production. A rough cut in the shape of belt is first to made from a block of steel. That rough shape is only the starting point. Then, the steel block is taken to shape it into a final mold by another machine. The process is so accurate that Jincheng aluminum die casting pays to treat making the mold with enough quality and detail.

Hot chamber die casting mold is another kind of qualified mould. Such a mold is employed chiefly for metals that melt at low temperatures, like zinc or magnesium. It is called a hot chamber because the liquid metal placed in this location, stays at an appropriate temperature until it should be poured into such mould. This helps in making sure that the metal flows into mold disorderly.

If you want to speed up production, instead of a single cavity mold use multi-cavity mold. This mould is made of several cavities; parts are usually produced at the same time. Jincheng aluminum die casting suppliers will save much time and materials but the results are accurate. Make several in one swoop. Want to multiply your compliments for yourself - even more than just doubling them, as in baking a batch of cookies vs. one cookie.)

A hot runner mold is another way to enhance the speed of production. The type of mold doesn't have to use runners - channels that route the liquid metal into places where parts will be formed. Also, the mold eliminates waste and releases faster because there are no runners. This is great because that metal will go into less waste, and in a shorter time even more products can be produced.

The mold needs to be carefully crafted and repeatedly checked for any issues in order to uphold this accuracy. At regular intervals, the workers have to examine on whether if there is any flaw or deformation in a mold. Anything which needs fixed should be, the quality in every final product is maintained>(means you keep higher). A focus on such detail sets the stage for a monsoon of production.

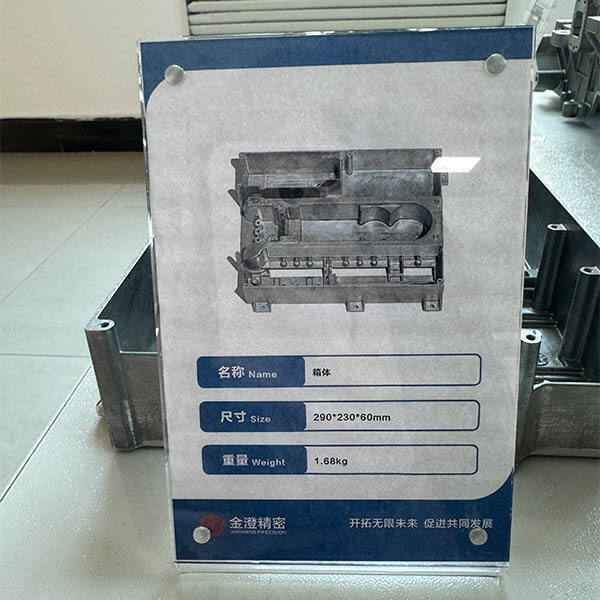

We have our own 3 major Aluminium die casting mold, Weitang auto parts casting plant, Suzhou Jincheng precision casting plant, Xuzhou Jincheng precision casting plant; the total asset size has exceeded 1 billion yuan and covers an area of more than 300 acres, and has a plant space that is 180,000 square meters. The plant has over 600 CNC machines with more than 60 vertical machining centers as well as complete electroplating, spraying and testing equipment. We offer professional precision machining solutions that are customized to our customers.

The product is manufactured in the company's own facilities. From purchasing raw materials to subsequent production and processing services We provide detailed pricing details. More than 80 expert mold engineers as well as 20 experts in die-casting are on hand at the firm. Our design for products is flexible and we are able to design molds to meet the needs of our customers, and also provide Aluminium die casting mold. It can provide conditions to produce small batches.

Our company was Aluminium die casting mold in 2006, specializing in traditional cars, innovative energy vehicles, telecommunications inverter, photovoltaic energy storage rail transit, medical aviation, as well as other custom aluminum alloy die-casting components and precision machining and general industrial components. We support 24-hour human online support and communications in minority languages. We can also provide a service team to connect with a project.

The Aluminium die casting mold production processes are supported by technical support and quality control, mold-making and die-casting, machine production and treatment of surfaces. Our company owns 150 - 4000 tons of fully automatic cold chamber die-casting islands production line 60, and advanced precision machine centers that are more than 600. The company also has a variety of high-precision instruments and measuring equipment, and a variety of other ancillary services. Its annual production is 50,000 tons and it is able to perform precise manufacturing and processing.