Did you ever wonder how cars are manufactured? With many steps it is a fascinating process. Die Casting is one of the key methods for making car parts. This process is essentially taking a metal (typically aluminum or zinc) and forming it into the exact shape of a car part. On this week of Wheel Science, we are going to examine why casting is so important and how it works in the automotive realm

Die casting is an accurate method of making parts for a car. Jincheng die casting products means it ensures that parts are of the correct dimensions. It is essential that these parts are manufactured in the right way, because if they do not work well or do not balance out properly then chances of a car working at all would be low For instance, if a part is grossly oversized undersized the chances are it may not fit with other parts and can also cause complications when driving.

Die casting is also a fast method to produce automotive parts. The process is fast, meaning car manufacturers could complete the step at no extra cost in a timely fashion. This is beneficial because it allows cars to be produced and sold quicker. In addition, die casting can produce many parts at once. It is from this mass production that we have the term. Mass production could help reduce the cost of cars for all. Lower cost cars mean lower sticker prices as well, which is great for all the drivers

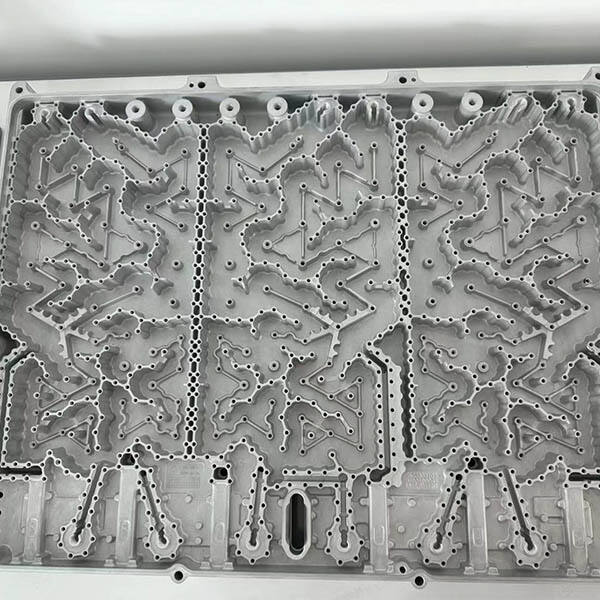

Really Nice Tools Die casting machines are very accurate. These aluminum die casting machines precision cut and form metal. It implies that car parts can be manufactured to high tolerances. For instance, if a car requires a component that is 10cm x 5 cm in size then die casting can create the same metal to those dimensions. This dimensional accuracy is significant since each of the many parts needs to be correctly implemented such as a puzzle that fits perfectly into place.

As we said, the process of die casting is a quick way to manufacture car parts. The Jincheng die casting process machines can quickly mold the metal into correct shape due to which no time is wasted. In short die casting can manufacture large number of parts at once. Producing many parts simultaneously may provide the possibility to reduce costs per part. Which means cars can be made more cheaply all up, which is good news for buyers. The price of cars is a very big barrier, when customers pay less for it - everyone drives cheaper.

Die casting provides economical way to produce car parts that are durable and stronger than other manufacturing techniques. The life of metal used in this method is very long and it can also work properly under tons of situations. When someone has the right parts in their car they can help it to work better and drive well. For instance, a car made with superior aluminium die castings parts could get better gas mileage and thus require fewer pit stops to put more fuel in the tank. Strong and trustworthy components can also improve an automobile's safety for you, the other occupants of the vehicle, as well as everyone else on those roads.

With electric cars at the fore-front of almost all automobile manufacturers, die casting is also an important part in creating parts for these vehicles. Jincheng die casting is used to produce parts in electric cars such as the motor casing and battery housing. This is achieved by die casting which allows for lightweight yet strong and durable parts. Lighter means further on the same battery charge for electric cars. A light car uses less energy to move. This is probably one of the most important factors due to the fact that you need light yet strong parts for them do what they were meant, hence die casting.

The product is manufactured in the company's own facilities. From purchasing raw materials to subsequent production and processing services We provide detailed pricing details. More than 80 expert mold engineers as well as 20 experts in die-casting are on hand at the firm. Our design for products is flexible and we are able to design molds to meet the needs of our customers, and also provide Automotive parts die casting. It can provide conditions to produce small batches.

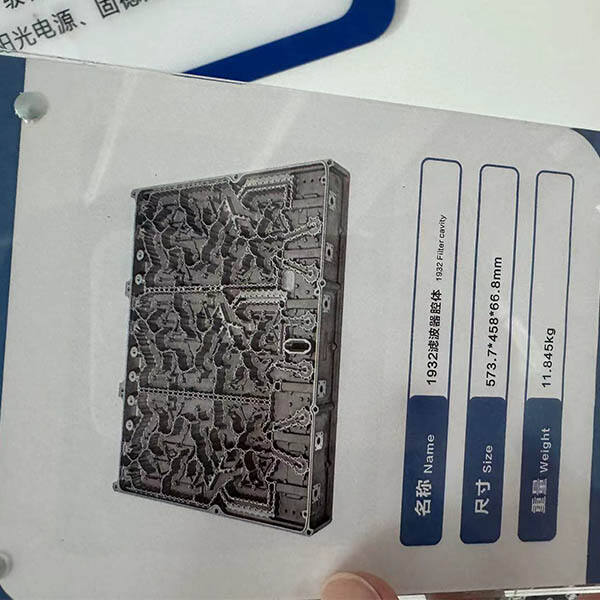

7 production process, technical support, quality control, mold production, die-casting production, machine production, processing of surfaces, as well as other facilities. Our company is equipped with 150 to 4000 tons of fully automated cold chamber die-casting island production lines 60, and advanced precision machines that exceed 600. Additionally, the company includes ancillary facilities as well as numerous large-scale precision measurement Automotive parts die casting and equipment, with an annual production of 50,000 tons of aluminum alloy die-casting components and research and development of parts, production and precision processing capabilities to get the impact of large-scale production.

We have three production centers: Automotive parts die casting auto part casting plant, Suzhou Jincheng Precision Casting Plant, and Xuzhou Jincheng Precision Casting Plant. The assets total exceed 1 billion Yuan and covers an area of 300 acres. Our plant covers 180,000 square metres. The company has more than 600 CNC machines with more than 60 vertical machining centers and complete electroplating and spraying equipment. We're dedicated to providing our customers with high-quality precision machining customized services.

Our company was established in 2006. was founded. We specialize in Automotive parts die casting aluminum alloy components in precision machining as well as general industrial parts. We offer 24 hours of human-to-human service online and also communication in languages of minority. We can also provide an expert service team to assist with a particular project.