Today, we are going to be looking at the alluring world of 5 cylinder engines, along with Jincheng's product gearbox house. The absolute perfect engine configuration that makes your drive just a little bit more exciting. This 5-cylinder combination in this motor makes a more pleasant sounding growl neither the angry bark of a proper V-6 nor than mousy burr from some as-cheap-as-they-are-lame four-bangers you hear on the economy car set.

5-Cylinder Engines: Almost As Awesome And More Efficient Than V6s

With numerous turbo charged engines across the lineup, these vehicles are able to provide potent power and swift performance on any highway while maintaining a powerful presence.

They also have an interesting lineage, originally developed for use in heavy-duty trucks where brute-force strength and reliability were the most important characteristics, identical to gearbox house built by Jincheng. That began to change in the mid-1990s-they started appearing even on regular cars. We have seen 5-cylinder engines move forward in a trajectory which technology promises increasing levels of power and efficiency, creating ever more refinement for the driver.

We investigate 5-cylinder cars to find out in the latest of our series on why they make great second hand buys.

Sonic Symphony: The wail of a 5-cylinder engine is sure to turn heads no matter where you are, same with Jincheng's gearbox house.

Power Boost: While the cylinder decrease might suggest less go, these engines can compensate with significant power gains thanks to their turbocharging ability.

The Clean Way to Drive: Due to its natural balance properties, a 5-cylinder engine delivers fluid power transmission - No unwanted vibrations, similar to the 4 cyl engine from Jincheng.

Reliable Durability: 5-cylinder engines are robust and last a long time so for future proof-quality, they can be a good pick.

Most often configured as 5-cylinder inline engines with a displacement from 1.8-2.0 litres, capable of anywhere between150 and 250 hp depending on the actual model;. They also have the option of being fed gasoline or diesel fuel and can be turbocharged to achieve increased power as well, identical to Jincheng's product gearbox house.

Going forward, things are looking up for 5-cylinder engines with the addition of hybrid systems and electric motors to improve both power delivery and fuel economy. Expect as these engines broaden their adoption throughout the range, you might well see more of that ideal blend between performance and eco-frieldliness on different types of vehicle.

Therefore, the future looks suspiciously bright for 5-cylinder engines which offer both their unique signature sound, superior performance abilities and ever-strengthening efficiency figures making them an appealing choice among more focused car buyers in years to come.

Our company was established in 2006. was founded. We specialize in 5 cylinder engine aluminum alloy components in precision machining as well as general industrial parts. We offer 24 hours of human-to-human service online and also communication in languages of minority. We can also provide an expert service team to assist with a particular project.

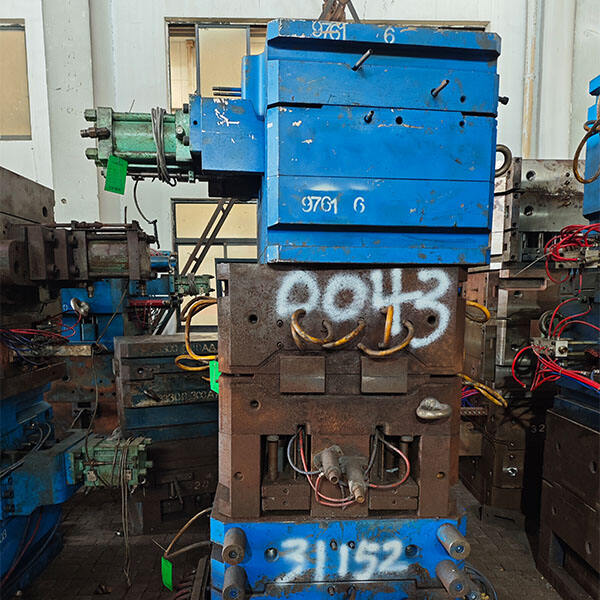

We own three main production centers Weitang auto parts casting plant Suzhou Jincheng precision casting plant 5 cylinder engine precision casting plant The total value of the assets is more than 1 billion yuan covers the area of almost 300 acres with a total area of 180 000 square meters The company has more than 600 CNC machines including 60 horizontal machining centres with complete electroplating spraying and testing equipment We are committed to providing our customers with high-quality precision machining and customized services

All of our products are produced at the facilities of the 5 cylinder engine they belong to. We provide all the information on pricing, from raw materials through production and services. The company is equipped with more than 20 die-casting industry experts and more than 80 mold professionals engineers. We offer molds and production solutions for our clients. Our product design is flexible. It can be used in small-batch production.

7 production process, technical support quality control, mold production, die casting production, machine production, surface treatment process, supporting facilities. Our company is equipped with 60 modern precision machining centers and fully automated cold chamber island die-casting production lines ranging between 150 and 4000 tonnes. The company also has dozens of large precision instruments and measuring equipment, as well as various related services. The 5 cylinder engine production of the company is 50,000 tons, and it can perform precision manufacturing and processing.