Aluminum -- Strong, light metal This is why aluminium plays a role in countless functionalities from the things we use everyday like planes, cars even kitchen utensils! An important use of aluminium is manufacturing parts by a process named as casting which we shall discuss later. Casting is a process when we heat the aluminium and pour it into molds in different shapes. These mould for aluminium casting are some of the features that you must count when it comes and aluminium casting parts will help us to get used

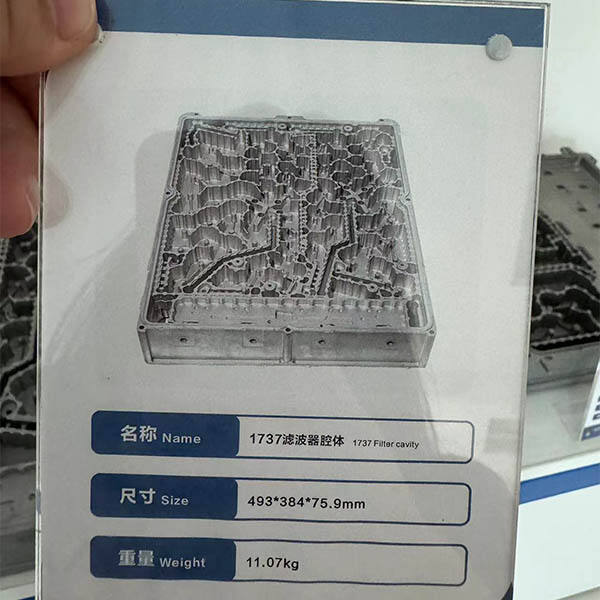

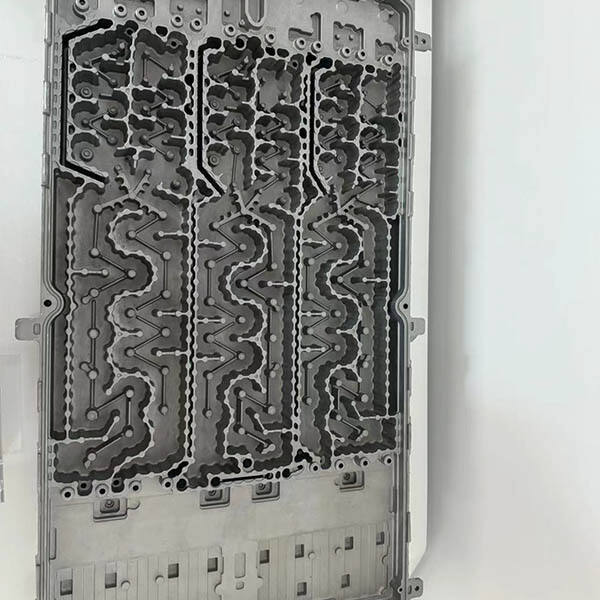

You can shape aluminum casting parts into multiple types and even the large sized ones. This is useful because we can directly melt aluminium and pour it into a mold. When cooled, it becomes hard and set in the shape of mold. Their ability to be molded into different shapes allows us to make parts that would otherwise be much more difficult or impossible using other materials. Only possibility in the design process.

It is also a feasible and cost-effective way for manufacturing parts when it comes to casting aluminum. Aluminium is great as one it can be melted back down and used again meaning we don't lose any materials. Because aluminium has a relatively low melting point, this means it requires less energy to reach its melting point than higher-melting metals. Jincheng aluminum die casting is not only good for the environment but it can also help you save money in energy costs over time.

Its lightweight characteristics sure do not hinder its being of an impressive strong metal. This makes it a great compromise for durable parts that will have extended use and need to endure high stresses. Moreover, Aluminium does not stain or corrode; thus, it lasts long in typical climate and outdoor conditions. This Jincheng die casting process property is especially important in parts used, for example, in aircrafts and automobiles - these require a reliable operation without fear of breaking down.

One more great aspect of aluminium die castings is that they can be designed a large amount in their style. It is also simple to swap the mold out in order that one design modification meets demand. This allows for leaner, faster iteration of our parts which is perfect when you work on a project that includes multiple different possible designs or need slight adjustments. This allows the engineers and designers to meet their project-specific needs without reinventing the wheel.

It is also a good choice for many companies that can perform well in quantities, and Jincheng aluminum die casting parts are solid components The mass-produce easily. This is critical for projects in which companies require large quantities of parts at once. Aluminium is one of those metals that are very strong and long lasting so it does not need to be replaced often. That way, businesses can save lots on materials and production over time. In the end, it helps to reduce costs, and that is why there are many companies willing to make this investment in aluminium casting parts.

In 2006, our business was established in the year Aluminium casting parts. We specialize in die-casting aluminum alloy components as well as precision machining and general industrial components. We offer 24 hours of human-to-human online service as well as communication with minorities in a variety of languages. We also have a service team to connect with a project.

All of our products are produced at the facilities of their Aluminium casting parts companies. We have all the details on pricing, from raw materials to production and even services. More than 80 mold engineers as well as 20 die-casting experts are on hand at the firm. Our product design is nimble, we can design molds to meet the needs of our customers, and also provide solutions for production. It is suitable in small-batch production.

We own three main production centers Weitang auto parts casting plant Suzhou Jincheng precision casting plant Aluminium casting parts precision casting plant The total value of the assets is more than 1 billion yuan covers the area of almost 300 acres with a total area of 180 000 square meters The company has more than 600 CNC machines including 60 horizontal machining centres with complete electroplating spraying and testing equipment We are committed to providing our customers with high-quality precision machining and customized services

7 production process, technical support, quality inspection, mold making die casting production, machine production surface treatment, and supporting facilities. Our company has Aluminium casting parts machining centers, completely automatic cold chamber island die-casting production lines ranging from 150 - 4000 tons. The company also has various ancillary facilities and numerous large-scale precision measurement equipment and instruments, with an annual production of 50,000 tons of aluminum alloy die casting parts and parts research and development production and precision processing capabilities to get the impact of large-scale production.